R&D Testing: Small to Large

At AGR, innovation defines us. Our journey in automation spans groundbreaking solutions, from intricate systems to revolutionary concepts. Our Research and Development (R&D) lab is pivotal, birthing, testing, and validating ideas.

Take, for instance, a recent project: automating packaging for a client, a task reliant on human labor. Our adept R&D team embraced the challenge, engineering a solution from concept to reality. Despite complexities, their commitment bore fruit. The result? A tested, proven system, instilling confidence in the client.

Our prowess lies in scaling projects, regardless of size. Small sparks of innovation often burgeon into substantial endeavors. Our scalable solutions optimize production, enhance efficiency, and validate concepts swiftly, saving time and resources.

At AGR, we're more than automation; we're innovation incarnate. Our R&D lab dedication and project scalability set us apart. Whether you're a novice or an industry leader, we're poised to turn your vision into success.

Explore AGR's offerings at www.arthurgrussell.com.

Let's innovate together

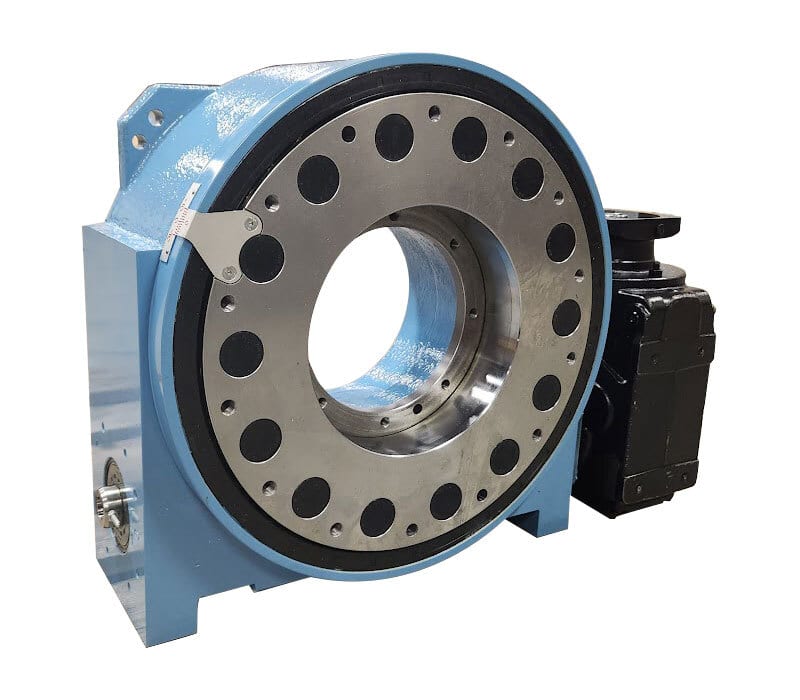

Trunnion Rotary Index Drives

Trunnion index drives are mechanical systems that rotate or index objects in machinery or equipment. These drives provide accurate and controlled object rotation to specific angles or positions for various applications across a broad industry range.

Motion Index Drives offers zero-backlash, programmable and fixed trunnion drives for all your automation needs. Benefits of fixed trunnion index drives is their low integration cost. These drives feature an internal barrel cam that provides a mechanically fixed degree of output. The units are essentially self-locking, delivering smooth acceleration and deceleration with a mechanically fixed dwell at a specific degree of rotation.

Programmable trunnions use a servo motor to control the motion and speed. These drives are programmable to work with various component types and sizes. This feature is especially beneficial for automation systems that require occasional adjustments, such as angle or torque modifications.

Another primary benefit of our programmable trunnion index drives is their flexibility, allowing you to retool the line for something new by programming it precisely as you need. Our RT, TMF and TR Series can accommodate any make of AC motor with absolute or incremental encoders for positioning. All our programmable vertical rotary indexers are adaptable to fit the correctly sized robot motor..

Worksmart Systems

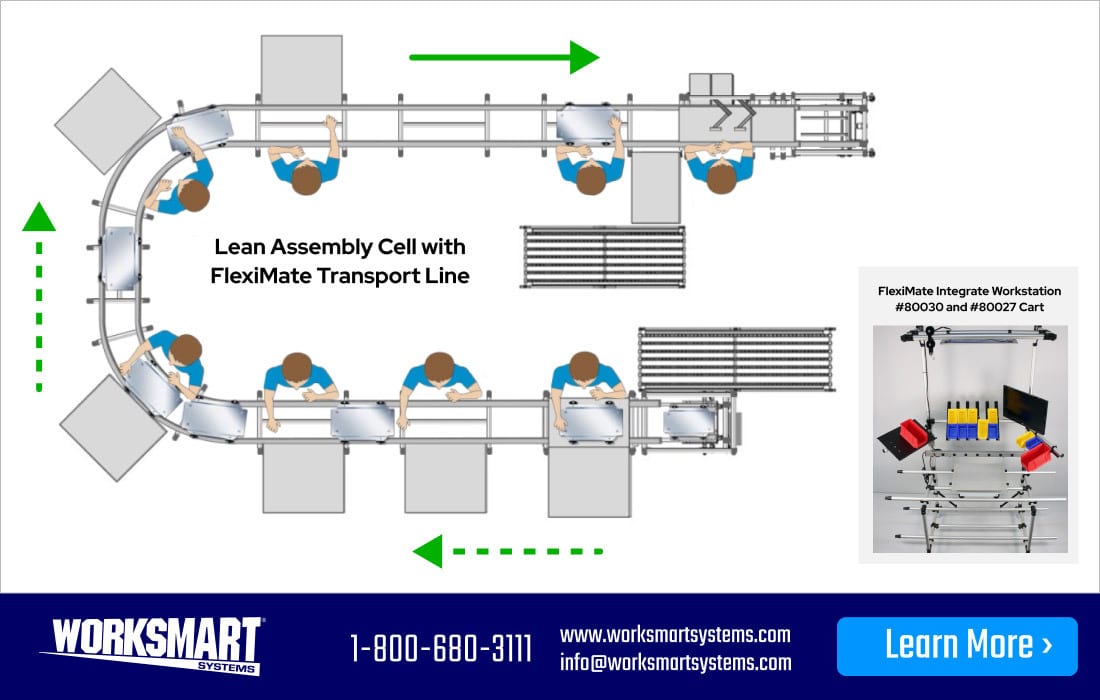

Fleximate Transport System: A Smarter Approach to Lean Manufacturing

Our modular system combines the efficiency of a conveyor with the ergonomics of a modern workstation—resulting in significant productivity gains. The Fleximate Transport System enables production to move seamlessly on carts guided by track tubes, connecting a series of workstations. This setup creates a lean manufacturing cell with true single-piece flow, dramatically reducing wasteful handling.

System advantages include:

• Single-tool adjustability for simplified, continuous improvement.

• Numerous options for parts presentation, tool handling, worker comfort, and equipment integration.

• Proven performance, with the ability to handle products up to 400 pounds.

• Components such as curved track sections, turnstiles, and vertical lift units to support unlimited cell configurations.

Stations can be used for online assembly, testing, rework, inspection, and pack-out. The system also supports smart tool integration, fixturing, and error-proofing (poka-yoke).

Thanks to its simple modularity, Fleximate cells can be quickly reconfigured or relocated to meet changing production needs and accommodate mixed-model manufacturing with minimal downtime. Our durable, low-maintenance construction minimizes disruption and keeps your operations running smoothly.

If you need assistance developing a lean cell concept, contact our experts. We’ll help define your goals and show you how the Fleximate Transport System can support your success.

Contact us today to get started.

Electric Press for Hazardous Locations

The Promess H-Series Press is a high-force, electric servo press engineered for mission-critical applications, including those in the defense sector. Delivering precise force and position control, the H-Series ensures optimal performance and safety—even in hazardous environments. Designed with intrinsically safe features and available in C2 Div1 compliant configurations, it’s ideal for operations where explosive materials or high-risk conditions are present.

Built on Promess’ proven closed-loop technology, the H-Series provides real-time feedback, ensuring accurate measurement, traceability, and control in every cycle. Its electric design eliminates the need for hydraulics, reducing maintenance and increasing efficiency, while supporting clean, reliable operation.

Whether deployed in standard production or hazardous locations, the H-Series Press offers the precision, adaptability, and safety demanded by today’s most critical manufacturing operations. Promess application specialists are available to tailor a solution to meet your exact requirements.