features

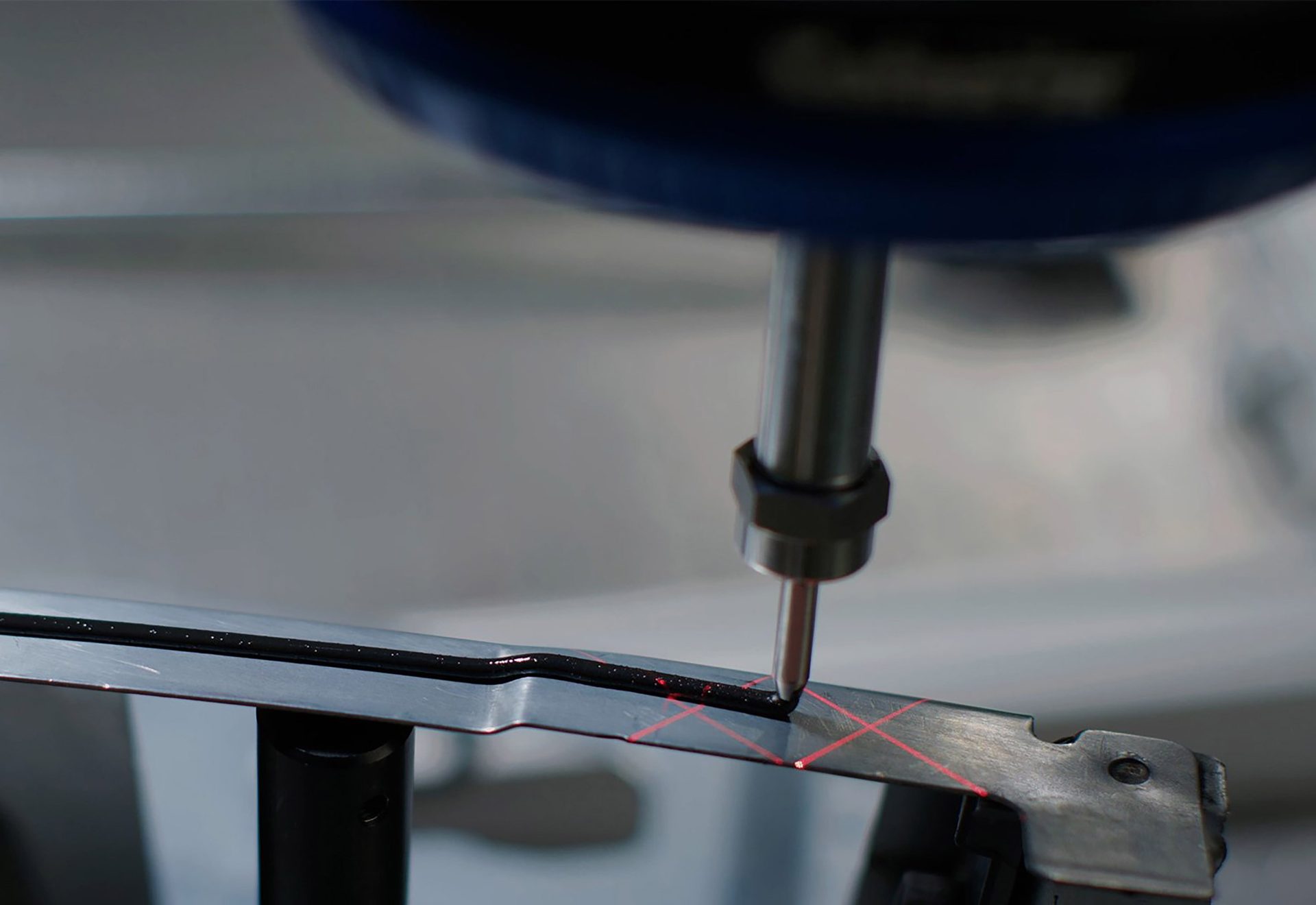

These tips and technologies can ensure that the right amount of adhesive is dispensed in the right spots.—Austin Weber

How to Error-Proof the Dispensing Process

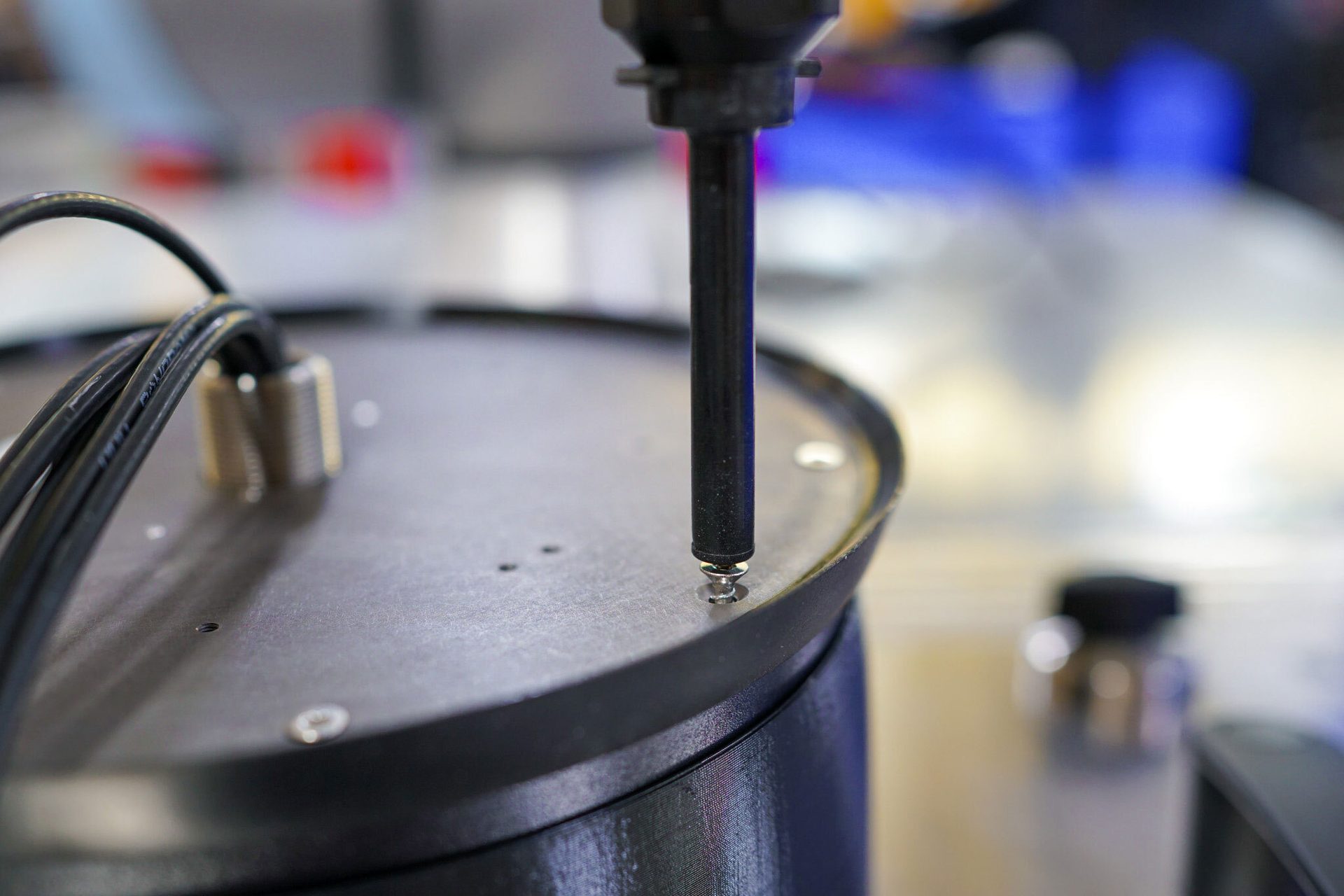

Automating the screwdriving process increases throughput, improves quality, reduces the risk of repetitive stress injuries.—

John Sprovieri

Cobot Automates Screwdriving at Electronics Company

Software enables Ancra Aircraft to optimize its assembly process by replacing text-based work instructions with animated, model-based, visual instructions.

—Fil Aronshtein

Aerospace Supplier Deals With High-Mix Production

A fantastic design can fail if engineers don’t choose the right fastener and assemble it correctly.—Jennifer Pierce

Fastening Failures: The Top Five Mistakes and How to Avoid Them

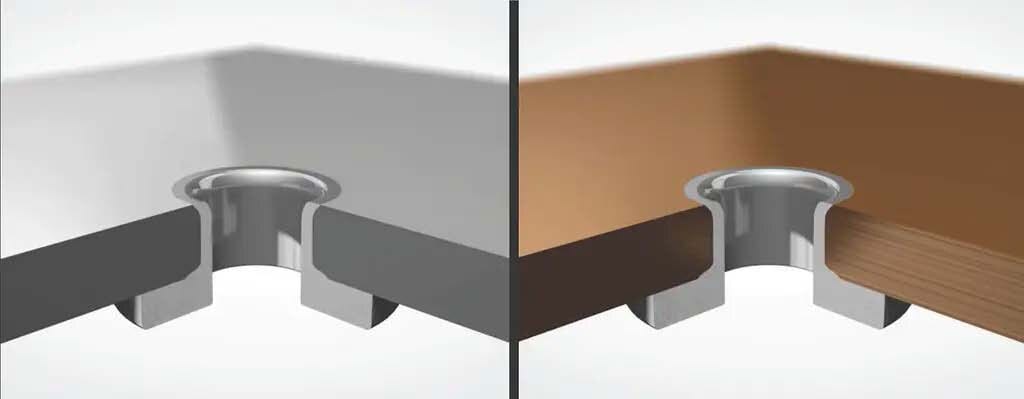

Self-clinching fasteners solve problem of metal oxide layers on copper and aluminum parts.—John Sprovieri

Contact Bushing Assembles Aluminum Bus Bars for EVs

Advancements allow the process to create larger, higher quality welds in less time.—Filippo Cortiglioni

New Technology Improves Diffusion Welding

ZF Lifetec employs both physical and virtual testing to ensure reliability and performance of seat belts, air bags and steering wheels.—Knut Zimmer

Product Testing Goes Digital

Nissan sold its first car in the U.S. in 1958, but domestic manufacturing did not begin until June 1983, when a white Nissan pickup truck rolled off the assembly line at a brand new factory in Smyrna, TN. More than 42 years later, Nissan has three U.S. manufacturing facilities capable of producing more than 1 million vehicles, 1.4 million engines, 1.4 million forgings and 456,000 castings annually. In this article, we take you behind the scenes at Nissan’s factory in Smyrna, which produces the Nissan Rogue, Murano and Pathfinder and the Infiniti QX60. Photo courtesy Nissan

About the cover

departments

Are you ready for the future? Asian manufacturers are.— John Sprovieri

From the Editor

Electric linear actuator is compact.—John Sprovieri

New & Noteworthy

Modular components lend flexibility to assembly lines.—John Sprovieri

See It At The Show

Humanoid Robotic Welders to Tackle Shipyard Automation.—Austin Weber

Assembly Lines

Nissan assembly plant rolls with the changes.—Austin Weber

Focus on: Automation

Interviews with leaders and innovators in product assembly.

Assembly Audible

Ad Index

Sourcebook Premium Sponsorship

Staff

In-depth profiles of the latest assembly technology.