ASSEMBLY ESSENTIALS

Meeting the Medical Moment!!

InterTech’s MicroScale Leak Testing

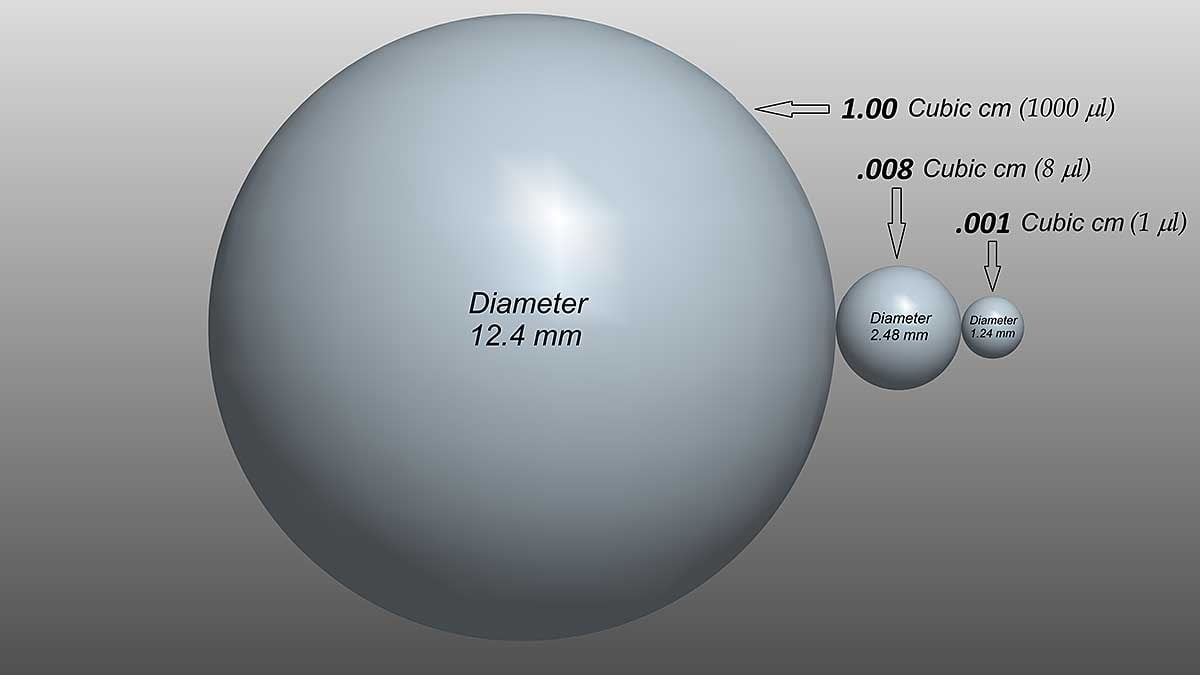

ASTM F2338 and ASTM F3287-compliant InterTech MicroScale leak testing systems-- testing down to microliters per minute—are being used for both in-line testing and audit requirements for a wide range of life science products including: rapid clinical testing systems; respiratory products; wearables; combined products; and a wide range of other medical devices.

InterTech’s turnkey MicroScale leak testing solutions --for both in-line testing and audit testing – have at their core InterTech’s unsurpassed patented test technologies--- superior mass flow test sensors, test sensor designs, and unique test fixtures.

- InterTech MED75 MicroScale Leak Testers

- Dual channel InterTech MED75 MicroScale Leak Testers control the test cycles:

- COVID19 Diagnostic Sample Transfer Device audit testing (GRR<10%) and production testing (GRR<20%) to a 0.008 sccm (8 microliters/min) limit at 682-710 mbar;

- Moisture Resistance Testing of Combination Products (e.g. canisters of respiratory inhalation devices) are leak tested at rate of 0.2 sccm (200 microliters/min) in 0.75 seconds test time;

- Container Closure Integrity (CCI) Test of Sealed Pharmaceutical Containers identifies leaks as small as 0.002 sccm (2 microliters/min) --equivalent to less than a 0.5 micron hole size.

Built-In GMP

GMP implementation is built in to all InterTech solutions—cutting waste and losses, as well as protecting medical manufacturers, drug processors and end-user patients from any negative product safety events.

- Product quality traceability is assured by deterministic test technology that eliminates potential for lapses in human operator judgements over entire product lifecycle.

- 21 CFR 11 data requirements are built into all InterTech test instruments and testing solutions.

- EtherNet/IP capability of test instruments allows seamless integration of test data in to all quality assurance systems.

- InterTech’s patented test technology eliminates the errors (both false positives and false negatives) inherent in previously used pressure testing methods.

- Online access to test instruments and all test cell controls enables remote machine acceptance and installation supervision, required by pandemic safety considerations.

March 2021

ESSENTIALS