Assembly Software

Jim Camillo // Senior Editor // camilloj@bnpmedia.com

The capabilities of manufacturing execution systems software have greatly expanded in recent years, making it a must-have tool for manufacturers in the age of Industry 4.0.

Make the Most of MES

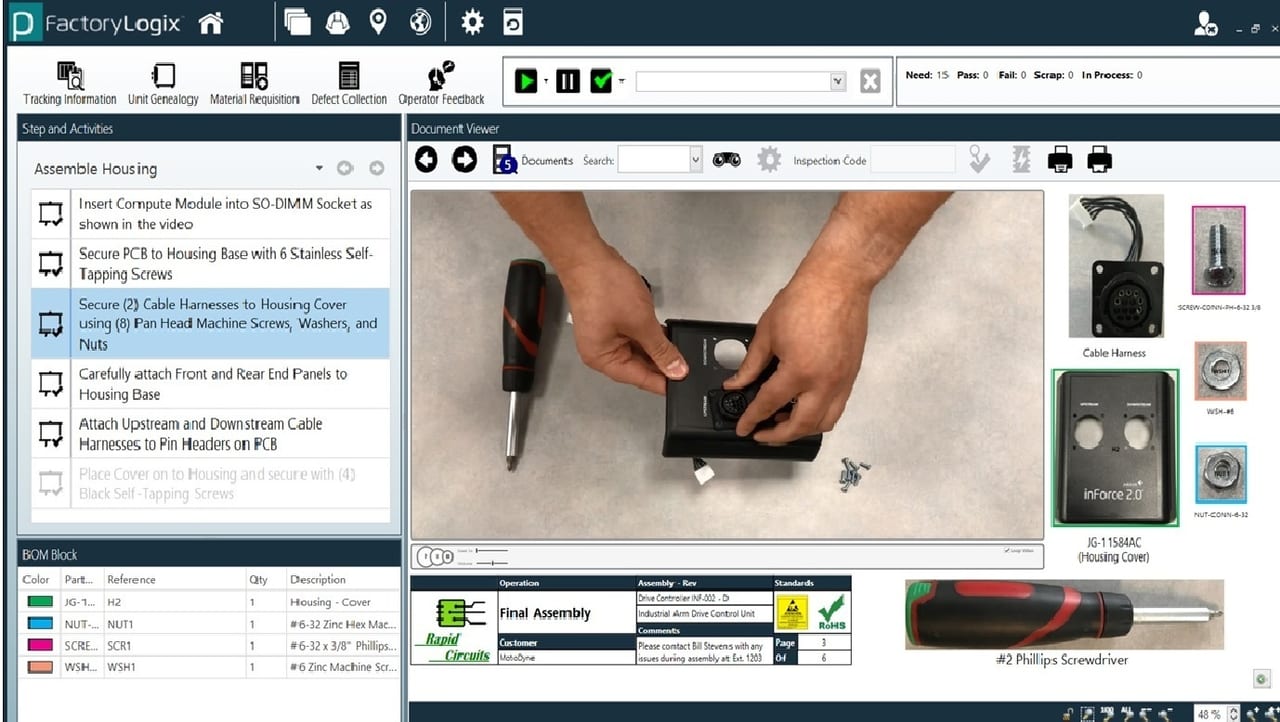

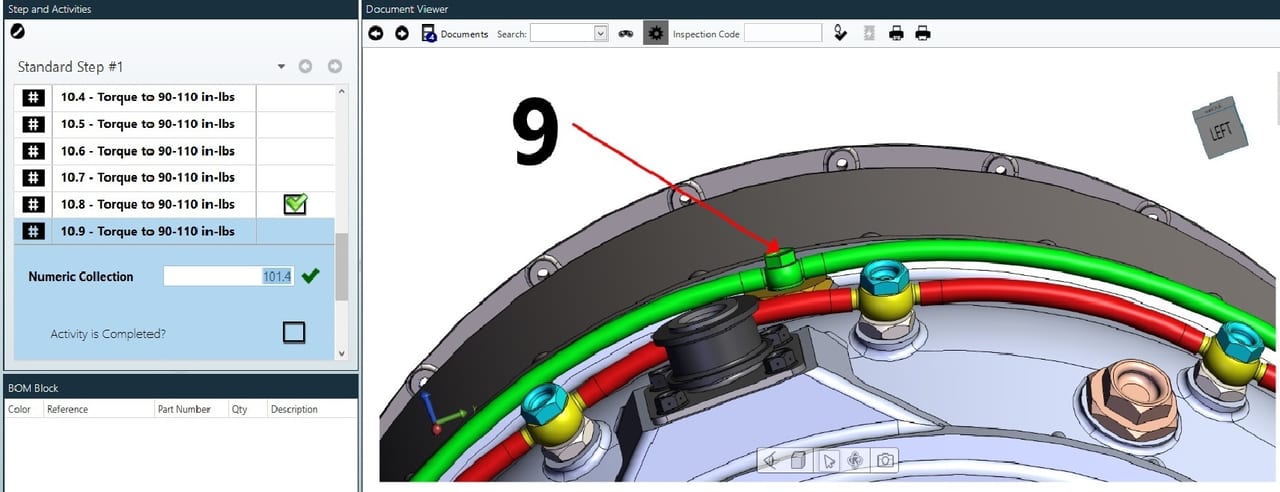

MES capabilities within the Manufacturing Integrated Platform include verifying tool torque during fastener installation. Photo courtesy eFlex Systems

When people say that two foods are better together than separately—like peanut butter and jelly, or macaroni and cheese—they’re giving simple examples of the benefit of synergy. A similar type of synergy has developed in recent years between manufacturing execution systems (MES) software and other types used by manufacturers.

“Our customers regularly use MES to complement and enhance their enterprise resource planning (ERP) software,” notes Ben Marsh, president and CEO of Scout Systems Inc. “Any ERP system is only as good as the data it has, and today’s MES software is capable of acquiring and providing great data. Personally, I think the goal of MES has always been to complement ERP.”

The Scout Systems MES is a two-tier platform (Lean and Pro) that helps manufacturers create digital work instructions, as well as monitor their assembly machines and processes. The latter capability enables companies to standardize production, improve quality and streamline maintenance.

Last year, this software helped a wire harness manufacturer determine exactly why its assemblers became fatigued when using manual crimping tools at one point in the assembly process. Marsh explains that a vice president of operations at the company saw this happen frequently on the computer monitor in his office and was troubled by it.

“Several workers significantly slowed down at one point in the process, and this was confirmed by the cycle-time data in the Pro version of our software,” says Marsh. “Together, though, the VP and our rep were able to analyze the work instructions and pinpoint exactly where and why the fatigue occurred. It turned out the assemblers assumed it was okay to use their shoulder in a certain manner to complete the crimping. Doing this increased the shoulder pressure, leading to fatigue. Assembly instructions were quickly changed in MES, and the problem is gone.”

MES software is by no means a new tool for manufacturing, having been around since the mid-1980s. However, for various reasons, manufacturers of all sizes in all industries often don’t take full advantage of the software’s capabilities. New benefits like scalability, affordability, low-code programming and traceability, complement traditional ones like error-proofing and optimizing workflow.

Stacked in the Manufacturer’s Favor

Not long after MES software became commercially available, the International Society of Automation (ISA) developed the ISA-95 standard in 1995 for an automated interface between enterprise and control systems. It is designed for all industries, and all sorts of batch, continuous and repetitive processes.

ISA-95 is a vertical model, with three main objectives. One is to provide consistent terminology for supplier and manufacturer communications. The others are to provide consistent information models and consistent operations models for clarifying application functionality and how information is to be used.

The standard, in essence, is a stack with five layers. At the bottom, Level 0, it focuses on sensors and signals for production processes. Above that is Level 1, for sensing and manipulating via a PLC. Level 2 is monitoring and supervising via HMI and SCADA (supervisory control and data acquisition). MES is at Level 3, for manufacturing operations management. At the top is ERP software for business planning and logistics.

“The broadest layer in the stack is MES,” says Dan McKiernan, president of eFlex Systems. “This is because 10 companies may have a different definition of what MES means to them. Despite this, they know that MES may be their best tool for optimizing the assembly line. Many users still resort to using spreadsheets with manually entered data, various in-house methods, printed documents like flip charts and even stop watches.”

The turning point for MES evolution occurred about 10 years ago, according to McKiernan. Software available up to that point was quite expensive and used only by large companies. The latest MES software, in contrast, is affordable for any size company, with low financial risk. It is also quicker to roll out, scalable, fully web-based and provides more accuracy and detail about manufacturing operations.

“Before MES, companies were forced to rely heavily on paper documents and other extra-time-consuming practices,” notes Marsh. “Imagine having to still do that in light of the current environment involving supply chain and labor shortages. With MES, you can address these challenges and still be efficient. Plus, you can take baby steps into the Industrial Internet of Things (IIoT) while continually learning about the software’s many capabilities.”

With FactoryLogix software, manufacturers can easily create interactive work instructions. Photo courtesy Aegis Industrial Software Corp.

Bob Miklosey, vice president of product management at Aegis Industrial Software Corp., cites complete automation control, real-time visibility, gathering of real-time data and improved product quality as some of the main benefits manufacturers receive from MES. Being able to lower the cost of regulatory and customer compliance for product build history is another advantage.

“MES truly is a key pillar in the stack, or set, of must-have industrial software for manufacturing and assembly,” says Miklosey. “It provides the best support for the factory floor, comparable to what ERP does for business management and planning. Floor managers no longer need to deal with disparate software programs and silos, like Access and Sequel, to optimize production.”

“The capabilities of MES are so vast it’s understandable that end-users don’t take advantage of them all,” says Marsh. “Manufacturers focus on the tangible things on the assembly line that make their products, such as how well a robot or piece of automation works on a daily basis. Eventually, they learn that MES can raise the capabilities of this equipment and the assemblers. Most of our customers see a 10 to 15 percent production increase in both areas.”

To make the most of MES, Miklosey recommends manufacturers compare using the software to taking a journey that can last for years. Doing this often requires management to change the company culture regarding the use of new software. Overcoming worker resistance to this is never easy, but doing so definitely pays off.

“It is totally fine for users of MES to crawl, then walk, then run with it as time goes by,” acknowledges Miklosey. “They can start modestly and expand. Maybe begin with creating interactive and animated work instructions. Then try some product tracking and data acquisition applications before moving on to material and quality management practices.”

Aegis’ FactoryLogix MES software is currently used in more than 2,000 factories worldwide. Most customers use it to optimize discrete manufacturing processes for mission-critical applications, according to Miklosey. End-users include manufacturers that serve the automotive, aerospace, medical, consumer products, telecommunications and computer-networking industries.

“Our platform can be easily upgraded and customized, and it utilizes a single code,” explains Miklosey. “It is device agnostic and serves as the digital thread between product lifecycle management (PLM) software and the factory floor to provide operators with interactive 3D.”

Types of data include animations and multimedia, images, video, PCB design files, detailed parts from PLM and that collected for implementing a digital twin. The platform also helps manufacturers optimize the functional and business value of non-redundant data. Management can capture defects, compare the data with models, and merge that data with existing IIoT data feeds to provide visibility and traceability.

Performance-Based Popularity

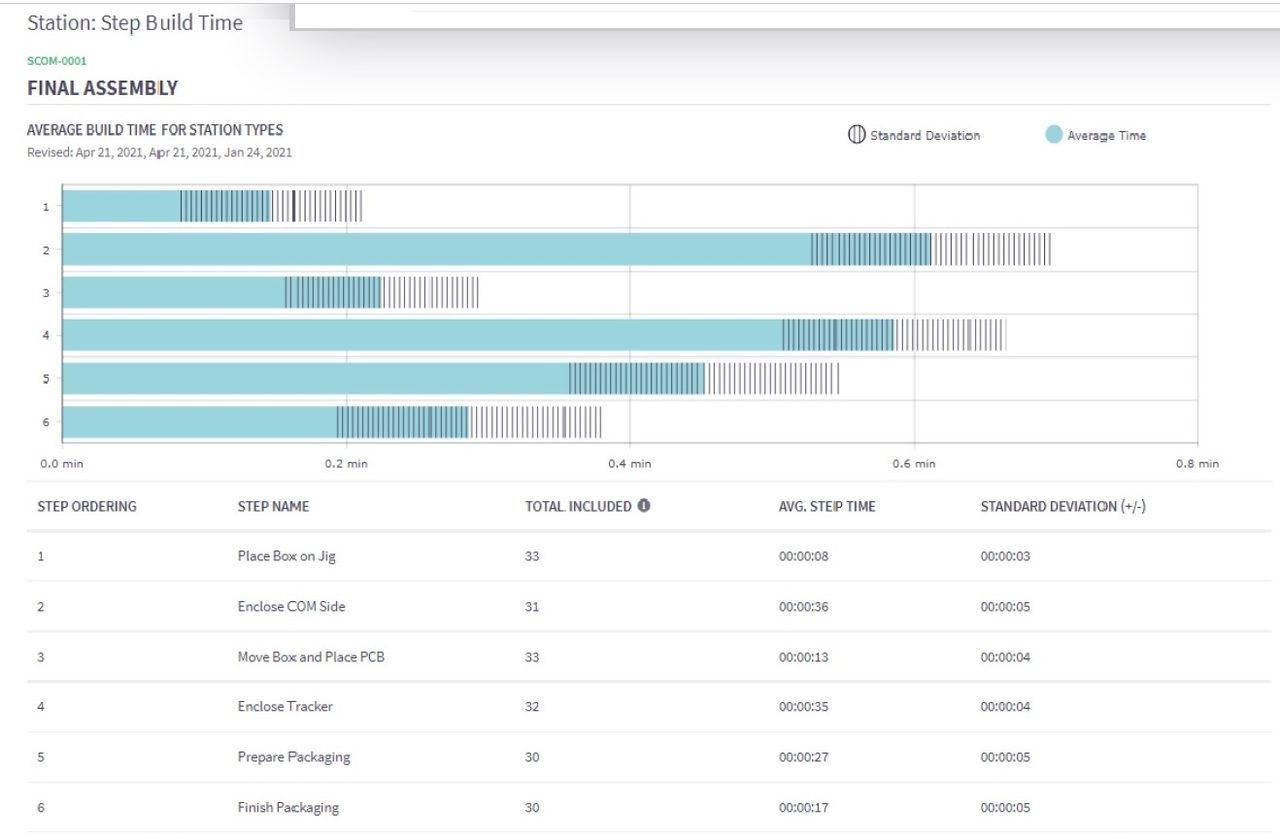

Scout Systems Lean and Pro MES software provides detailed data for all types of assembly. This graphic shows the average build time of each step at a workstation. Graphic courtesy Scout Systems Inc.

MES software continues to grow in popularity among fabricators and manufacturers. Marsh says 50 to 55 percent of Scout Systems MES users emphasize assembly, compared to 30 to 35 percent for fabrication and 10 percent for molding.

“I tell customers to focus on the software’s end-deliverables, rather than just a list of features,” says Marsh. “While it is nice to be able to press a button and quickly do something, it is better to understand MES at the operational level.”

According to McKiernan, MES popularity is partly due to the software becoming a necessity rather than a luxury for manufacturers. He says that digital transformation on the factory floor is a must for companies who want to keep up with competitors. MES is an effective way to achieve that transformation.

“The software’s use is definitely on the rise,” adds McKiernan. “One reason is more suppliers are entering the marketplace, giving companies greater access to a larger selection of software. But, even more importantly, manufacturers want to evolve to achieve greater flexibility on the factory floor and higher profits.

“The more assembly and manufacturing processes you use MES for, the greater the return you’ll get from both equipment and people,” continues McKiernan. “This is crucial for manufacturers as they continually experience worker turnover and increasingly lose veteran workers and their tribal knowledge to retirement. With the help of MES, a company can capture that knowledge from its most experienced workers and use it to train new hires.”

Miklosey says a big part of MES’ appeal is its ease of use and intuitiveness. The software is Windows- or web-browser-based, its basic and advanced features are easy to find, and suppliers usually provide in-person training and online tutorials that cover a range of functions and implementation challenges.

“The best approach to implementing MES is to determine the key business goals that need to be achieved and work backwards,” claims Miklosey. “This avoids endless wading through technical specifications and functionalities that can often appear confusing until the context of what is needed is clarified.”

Goal number one is assembling high-quality products and having them ready for shipping, according to Miklosey. MES software does this in two ways. First, by visibly showing the status and performance of all processes at all times. Second, by determining the plant’s overall capability to meet delivery goals when many product types are being simultaneously made.

“Live tracking of products and subassemblies is an MES cornerstone,” notes Miklosey. “It supports customers’ single-piece flows where the order detail automatically determines the process.”

As for software selection, Marsh says it should closely match your company’s short- and long-term goals. He also advises picking a supplier that provides technical support whenever the end-user needs it. This is especially crucial for companies that run multiple shifts on a daily basis.

Scout Systems has provided its MES product on a software-as-a-service (SaaS) basis since its introduction in 2015. Marsh says SaaS significantly lowers the entry cost for manufacturers looking to use MES. It also lets end-users fully test the software at a lower risk than buying it outright.

“By focusing on cherry-picking easy improvement projects, managers can achieve a surplus value within 90 days,” according to Marsh. “On average, it takes 3 to 5 hours to setup the platform, followed by 1 to 3 hours for a custom installation, and 30 minutes for operator training.”

The analysis phase of using the platform encompasses performing a complete data review, doing an ROI worksheet and identifying realistic change projects. A scaling worksheet is completed during the process improvements phase. Once the plant is digitized, managers can use the platform to more easily discover true waste and hidden bottlenecks.

EFlex offers its Manufacturing Integrated Platform, which essentially replaces all of the layers of the ISA-95 stack. McKiernan says MIP helps manufacturers address the issues presented by legacy systems, aging infrastructure and outdated technology--while simultaneously overcoming the challenges of a digital transformation.

EFlex first did work on this type of platform back in the late 1990s for General Motors. By 2013, the platform had evolved and been rebuilt with a modern web-based open software stack. The current version has been available to all manufacturers as an SaaS since 2017.

One unique feature of the MIP is it is no-code, meaning it requires no coding or scripting to set up and get running, says McKiernan. This lets people closer to the actual process take ownership of it, rather than highly technical resources that are outside of the company and expensive. For areas where end-users may need custom integration to equipment or processes, the company has a low-code programming tool called Node Red.

“Where our software is installed, we find that manufacturers are concerned about controlling their equipment and processes from the cloud," says McKiernan. "So we enable them to do it on-site behind their firewall, or in the cloud for maximum flexibility.

During a pilot program, they tell us the sequence and events they need for each workstation, and we help them configure it during installation and training," continues McKiernan. “This approach lets them continue expansion without expensive outside resources. Once implemented, the platform collects data from people, processes and assets, before turning the data into real-time visibility and operation insights for continuous improvement.”

The number of features a manufacturer requires in its MES usually depends on how much manual assembly is performed at a plant. According to Miklosey, each manufacturer alone must determine the functional scope it will adopt in its digital transformation.

However, software scalability becomes important should the company decide to change its approach in the future. FactoryLogix, for example, is versatile enough to effectively optimize high-mix, low-volume manufacturing, as well as low-mix, high-volume and continuous-flow manufacturing.

Some Trends to Watch

Device agnostic, FactoryLogix software directly provides operators with the actual 3D design of mechanical parts and assemblies. Graphic courtesy Aegis Industrial Software Corp.

The state of MES for assembly in 2022 is one of robustness, with suppliers continually expanding the software’s data-gathering and interactive capabilities to better serve end-users. This is great news for manufacturers looking to more accurately record the performance of torque and other tools, according to Marsh.

“Our Pro version of MES provides this level of equipment control and data collection,” says Marsh. “Manufacturers can easily set torque parameters for each tool, then change it as they need to, and verify that the change is done. The same technology can be used with test equipment, to determine good and bad parts, as well as various other machinery.”

Miklosey says some end-users increasingly prefer using MES systems that prioritize baseline and scalable business intelligence (BI) analysis. These systems let companies access the software’s terabytes of native data with no need for third-party integration. Insights from this data help manufacturers be more responsive to their customers’ needs. FactoryLogix, for example, is readily accessible by the manufacturer’s BI platform of choice.

Meeting the IPC’s Connected Factory Exchange (CFX) standard in MES is another challenge being addressed by software suppliers. Aegis greatly contributed to the development of the CFX, which emphasizes plug-and-play connections to simplify machine-to-machine communication, analogous to USB computer devices.

Recently, Aegis announced that Lockheed Martin’s Lufkin, TX, facility connected several of its automated assembly machines according to the IPC-CFX standard. Doing this enables the company to obtain all IIoT data in real time on its FactoryLogix MES platform.

“We now have just one manufacturing data protocol, with a single standard language, [which] greatly simplifies our manufacturing IT requirements,” concludes Jarrod Webb, manufacturing robotics engineer at Lockheed Martin. “Only in this way could we achieve our data-driven, smart manufacturing goals.”

ASSEMBLY ONLINE

For more information on MES software, visit www.assemblymag.com to read these articles: