Screwdriving and Riveting

Labor shortages are driving new demand for automation.

Options for Screwfeeding

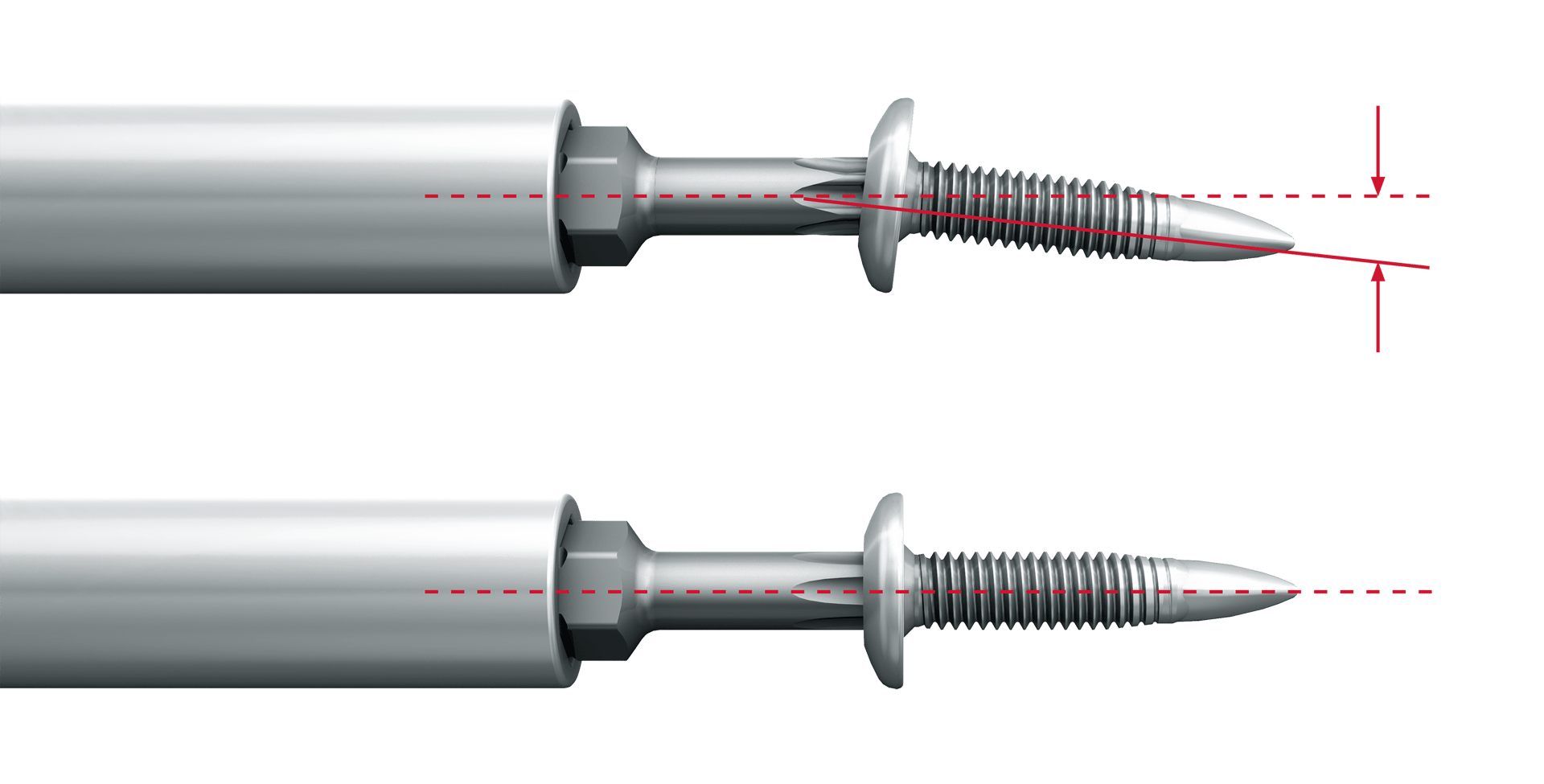

The design of the TOBI drive is based on a combination of large concave and small convex radii, resulting in a vertical wall recess whose six sides are gently curved until they intersect with the opposing wall in a relatively sharp, but radiused intersection. Illustration courtesy EJOT

The new TOBI drive recess enables screwdrivers to retain fasteners without the need for magnetics or vacuum.

Conundrum

Solving the Bit Stick Assembly

Markus Duchardt, Ph.D. // Vice President of Licensing and Business Development // Fabian Unterderweide // Head of TOBI Drive System // The EJOT Group // Bad Berleburg, Germany

Imagine you are standing on a ladder six feet in the air replacing a light fixture. In one hand, you are supporting the weight of the fixture as you align it with the electric box. In the other hand, you are precariously balancing the mounting screw with a cruciform drive on the bit of a screwdriver. As you gingerly raise the screwdriver to the mounting hole, the tip grazes the edge of the fixture. The screw plummets to the floor. Now you are in a predicament. You cannot let go of the light fixture to retrieve the fallen screw, but it is too far below to reach without dismounting the ladder.

Such an occurrence is an ordinary setback to a handyman. In a high-volume assembly operation, however, regular or intermittent dropping of screws during installation can be catastrophic. To prevent that from happening, manufacturers often employ sophisticated methods to guarantee that screws with an internal drive recess are delivered to the assembly point and successfully driven every time.

But, what if the internal recess itself delivered all the qualities necessary to achieve successful installation without needing additional sophisticated technology?

Just such a recess is available: the TOBI drive. The TOBI drive is a lobular, vertical wall recess that is visually like other hexalobular designs. However, that is where the comparison ends. The design of the TOBI drive is based on a combination of large concave and small convex radii, resulting in a vertical wall recess whose six sides are gently curved until they intersect with the opposing wall in a relatively sharp, but radiused intersection. When paired with the mating driver bit, this configuration provides users with several important advantages: “bit stick,” improved bit-to-recess contact, bit strength and durability, and bit-to-recess alignment.

With drive recesses that do not have bit stick capability, the screw often droops from the bit and loses its axial alignment with the driver. Illustration courtesy EJOT

Better Bit Stick

Bit stick refers to the capability of the recess-and-bit combination to securely hold the screw in a set orientation while it is presented for assembly. The most challenging presentation is when the screw must be retained on the bit as it is advanced horizontally or vertically into a workpiece without additional holders or constraints. Such presentations often occur when screws are either manually or robotically driven from the side or from below. In fact, the scenario presented in the introduction illustrates a challenging vertical presentation and an example of why some of the most successful construction screws have bit stick capability.

See us at The ASSEMBLY Show South, Booth 1237.

The TOBI drive achieves this bit stick capability by combining a unique recessed drive geometry in the screw with a specially designed tapered tip at the lead end of the bit. The result is a strong bit stick capability, making screws with this drive well-suited to unsupported screw assembly from any direction. It’s also ideal for installing screws made from stainless steel and other nonmagnetic materials. Like other recess drives that exhibit bit stick, a genuine TOBI drive must be paired with a genuine TOBI driver.

The ability to hold, move and place screws made of nonmagnetic materials is a significant breakthrough for applications using fasteners made from stainless steel or nonferrous materials, as well as for applications where magnetic holders can damage or interfere with the surrounding components. Ordinarily in these cases, parts must be hand-loaded onto the bit, or the drive must be equipped with a complicated vacuum pick-up system. Manually picking up larger screws, although time consuming, is not difficult, but when it may be entirely unfeasible with micro screws. In such instances, engineers often resign themselves to sacrificing corrosion resistance or introducing magnetism to surrounding components for better assembly.

Finite element analysis of the TOBI drive shows that the resulting interface between the bit and the recess lobe walls imparts an even and low stress distribution over almost the entire contact area. Illustration courtesy EJOT

Improved Bit-to-Recess Contact

The gently radiused sides that comprise most of the recess profile allow for increased contact area with the mating bit both in radial profile and longitudinal depth. In fact, finite element analysis has shown that the resulting interface between the bit and the recess lobe walls imparts an even and low stress distribution over almost the entire contact area. This is a critical attribute, because with more engaged contact area than other lobular, vertical wall and cruciform recesses, the efficiency and potency with which it transmits torque is improved. Improved torque transmissibility is a strong function of a drive system’s ability to be driven or removed without damaging or “camming out of” the recess. It is also an important advantage when the recess is partially filled with paint or other contaminants.

Axial Alignment and Wobble Reduction

Due to better bit stick, screws with the TOBI drive maintain axial alignment with the bit without additional fixturing or holding devices. Screws with recesses that do not have this capability often “droop” from the bit and lose their axial alignment with the driver. A screw presented to its assembly point drooping off axis is prone to problems associated with misalignment, difficulty in finding mating threads or pilot holes, or entirely dropping from the bit.

A practical consequence of axial misalignment is “wobble” in the screw during installation. When the fastener and bit are not axially aligned, the resulting assembly is plagued by the screw turning in wide arcs or wobbling around its axis. Other lobular drive recesses are especially prone to wobble under high axial loading because of large tolerances and eccentricity of the recess and bit axes. Screw wobble is particularly troublesome because it can mar or scratch the surrounding material. Wobble can also lead to downtime while engineers troubleshoot how to eliminate it.

Bit Life and Durability

Another advantage of the improved bit-to-recess contact is improved bit life. Since the improved surface contact eliminates the point loading and resulting stress concentration of other hexalobular and cruciform recesses, the TOBI drive exhibits both improved torsional strength and fatigue life. Improved torsional strength and fatigue life equates to longer bit life. Comparative tests show that TOBI drive bits significantly outperform similar sized traditional hexalobular bits.

In comparative tests for torsional strength, the TOBI drive was found to be 30 percent stronger than Torx Plus and 60 percent stronger than Torx. Similarly, we conducted fatigue testing with size 25 drives at varying levels of torque. The data indicate that TOBI significantly outperforms Torx and Torx Plus.

Inspection System

In comparative tests for torsional strength, the TOBI drive was found to be 30 percent stronger than Torx Plus and 60 percent stronger than Torx. Illustration courtesy EJOT

On the surface, this advantage may seem inconsequential, but under closer scrutiny, increased durability and bit life equates to real cost savings associated with bit replacement, reduced downtime, and fewer resources invested in reworking and troubleshooting when a bit breaks. For example, in our fatigue tests, when the applied torque is 30 percent of the TOBI drive’s capacity, the Torx bit survives 8,100 applications; the Torx Plus bit survives 27,244 applications; and the TOBI bit lasts for 581,443 applications.

Sustainability in Manufacturing

It may seem odd to discuss sustainability in manufacturing in the context of an article about a new drive recess. But, in fact, the TOBI drive can help manufacturers reduce energy consumption and lower their carbon footprint.

When installing threaded fasteners, one of the most significant energy demands comes from vacuum systems that are used to pick and place fasteners for assembly, especially if the fastener is small, nonferrous, or cannot be placed with magnetic tooling. Vacuum systems use large quantities of compressed air, and compressed air requires large quantities of energy to produce. The TOBI drive eliminates the need for vacuum systems. Also, the improved bit life will result in less downtime and greater productivity.

EJOT conducted fatigue testing with size 25 drives at varying levels of torque. The data indicate that TOBI significantly outperforms Torx and Torx Plus. For example, when the applied torque is 30 percent of the TOBI drive’s capacity, the Torx bit survives 8,100 applications; the Torx Plus bit survives 27,244 applications; and the TOBI bit lasts for 581,443 applications. Illustration courtesy EJOT

Service

The challenge of any new recess drive system is the availability of tools for service. Within many industries, manufacturers often hesitate to introduce a new fastener design that will require field service technicians to have to invest in new tools, even something as simple as a new set of screwdrivers.

The TOBI drive answers this challenge. It is compatible with standard and highly available hexalobular tools. Using such tools for initial assembly is neither recommended nor optimum, as it eliminates the bit stick advantage. However, it is feasible to use a standard hexalobular bit to disassemble and reassemble a screw with a TOBI drive recess in the field.

Sample Applications

There are myriad applications for the TOBI drive recess.

For example, an excellent application is stainless steel screws for precision electronic memory devices. Although most modern memory devices are now solid state and no longer unstable around sources of magnetism, it is still best practice to minimize stray magnetism around precision electronic and memory components. Therefore, the use of magnetic bit holders may be unwise. With TOBI drive’s bit stick capability, no magnetic bit or vacuum assist mechanisms are necessary to hold the screw.

Miniature screws are another excellent application for the TOBI drive, especially those made of stainless steel or ones that possess very thin heads and shorter-than-average recess penetration. The TOBI drive’s bit stick advantage makes picking and placing these screws easier.

Additionally, however, the TOBI drive’s improved bit-to-recess contact area means that less driver penetration is necessary to gain the same amount of torque transmission as other drive recesses. As a result, the TOBI drive becomes an excellent option for wafer and flat head micro screws that have very thin heads, and thus, the need for shorter recess penetration depth. In this instance, the TOBI drive not only solves an application problem, but it’s more cost effective by making the assembly less complicated, more efficient, and less problematic.

One more excellent application for TOBI is construction screws for general purpose uses, drywall and decks. The bit stick feature will allow users to align their approach to the fastening site, whether horizontal or vertically overhead without fear of the screw drooping, falling off, or wobbling when an axial load is applied. Additionally, since no additional holder that is larger than the screw head is necessary, screws can be installed in hard-to-access locations.

ASSEMBLY ONLINE

For more information on screwdriving, visit www.assemblymag.com to read these articles: