Larry Weis // Contributing Writer

Leak Testing

Existing machinery can be repurposed for new leak testing applications, saving thousands of dollars.

Repurposing Leak Test Equipment for EVs

Automakers and component suppliers can save time and money by repurposing existing leak testing equipment for EV applications.

Leak testing automotive components to boost quality and reliability has become a critical part of the production process for carmakers and their suppliers. These tests are expected to become even more important as the industry transitions to electric vehicles.

That’s because an EV’s sensors and other electronics are more sensitive and require tighter tolerances than the components in vehicles powered by an internal combustion engine (ICE), explains Thomas Parker, Inficon’s North American automotive sales manager.

As a result, leak test systems for EV components need to meet more stringent performance requirements. They also must be adapted for changes in a vehicle’s structural design, material usage and key drivetrain systems. In addition, test procedures for lithium-ion batteries, electric motors, transmissions and other components need to be reworked for EV applications.

Making the Most of What You Have

The good news is that some producers don’t have to buy entirely new leak detection systems to test EV components. Automakers and component suppliers can save significant time and money by repurposing—and modifying—existing leak testing equipment for ICE applications. In some cases, Parker says, reutilization can cut costs by as much as two-thirds. Considering that an all-new system can cost $1 million or more, the savings can be substantial.

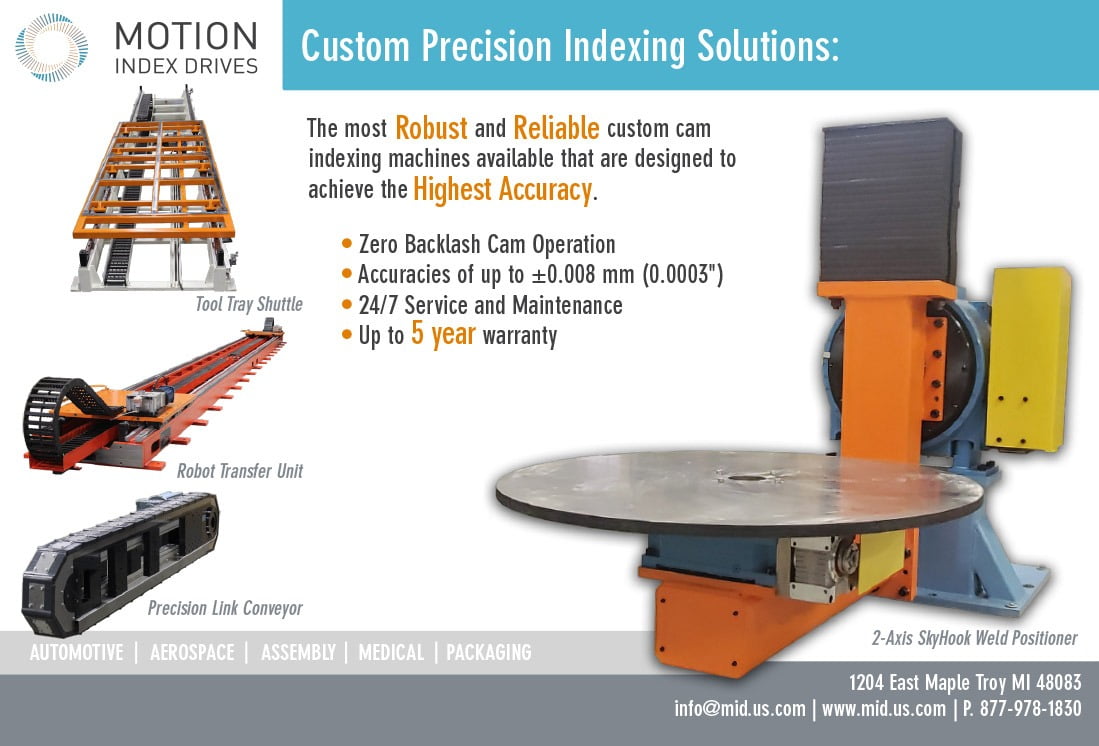

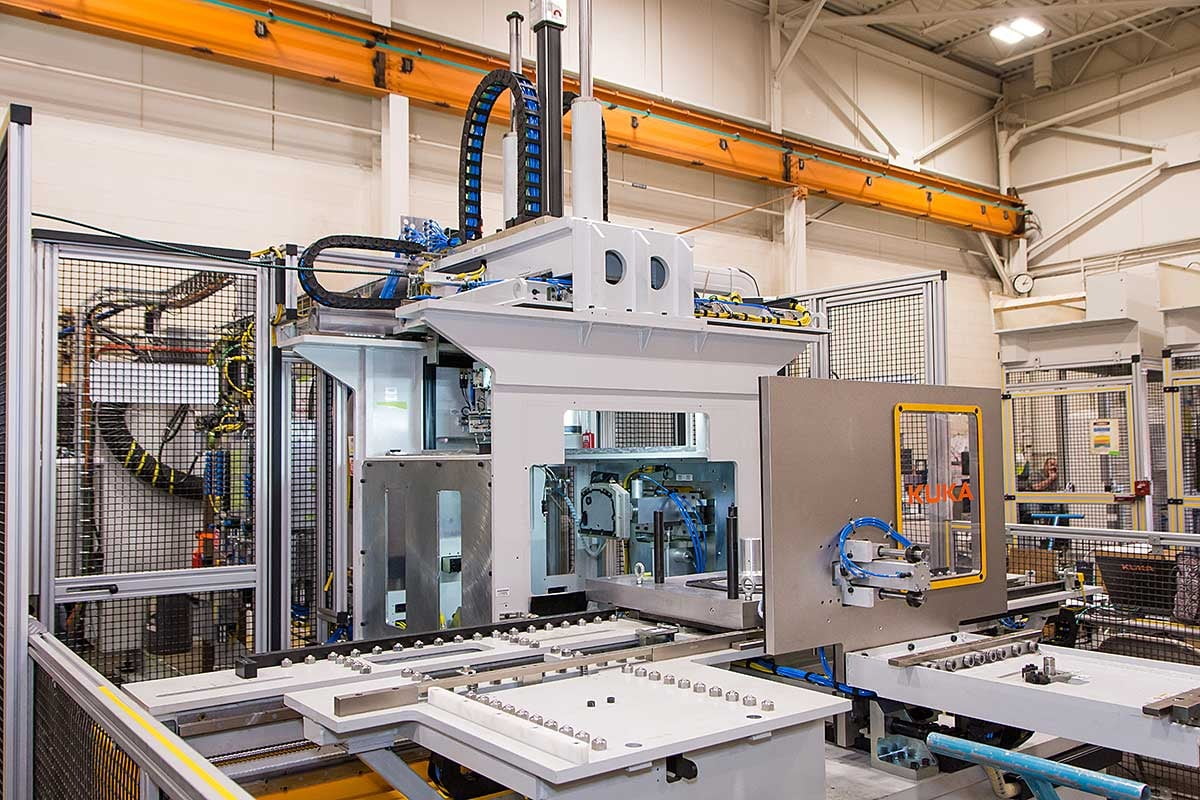

Working with KUKA, Inficon has taken the lead in developing repurposed automotive leak-detection systems in North America.

Benefits of reusing equipment can extend beyond the cost of the base test stand, notes Chip Darling, technical specialist leader for KUKA’s Product Performance group. Additional savings would come from reusing gantries, machining lines and other equipment and floor space.

“Companies want to make the most of what they already have,” Darling explains. “But there has to be a solid business case. Our job is to find the best solution and present the facts.”

A technician uses a helium-based leak test instrument to inspect automotive components off-line.

Getting Started

Regarding leak testing, the first step when switching to an EV program is for the manufacturing engineering team to conduct a process capabilities study. This includes a detailed analysis of equipment, vehicle design specifications and leak-test requirements.

“Companies need to know what their current leak detection system is capable of and compare that to the new program’s requirements in terms of testing sensitivity, speed and repeatability,” Parker notes. “An EV may need a lower leak rate, faster cycle time or different measurement certainty for the metrology.”

The evaluation of a robotic leak-detection system includes the test stand and subsystems, such as the programmable logic controller, the tracer-gas vacuum-handling unit and test instrumentation. All of these can be retrofitted to varying degrees.

An engineering study will determine what can be reused and what changes are needed. Everything from new vacuum pumps and larger chambers to different seal tooling or additional processing steps will need to be considered.

Modifications can either be made directly at the assembly plant or offsite by the testing supplier depending on the size and complexity of the system. The job itself can take anywhere from a few hours to several months.

After the equipment is updated, tests are conducted on prototype EV parts to prove the new equipment performs as intended. This means detecting leaks within specified time limits, Parker points out, and demonstrating that the process and measurements are repeatable.

Leak test systems for EV components need to meet more stringent performance requirements than those for ICE components.

Job 1

Inficon and KUKA teamed up last year to work on the installation of their first retrofitted EV leak test system. The repurposed unit will be used at a transmission plant in Michigan set to launch a high-volume EV program this summer, switching from a traditional nine-speed automatic gearbox to a one-speed unit.

Due to higher operating temperatures, EV gearboxes have internal glycol-and-water cooling circuits that are not found on automatic transmissions for ICE vehicles.

“An EV’s fluids, sensors and pressure rates all demand lower leak rates,” Parker says. “Problems that aren’t found through proper leak testing during the manufacturing process can lead to costly and much more serious problems once a vehicle is in service.”

KUKA’s retrofitted transmission test system required modified seal tooling and extensive changes to the vacuum handling chamber, due in part to changes made to the center motor housing.

Only minor changes were needed for the existing control system and Inficon’s LDS 3000 helium leak detector. The time required to complete each test remained the same at about 75 seconds.

Although there are less than half as many cavities to test in the new EV gearbox, the layout is more challenging because the openings for the electric driver and controller are adjacent. “We have to check for external leakage from each cavity on its own, as well as for internal leakage between them,” Darling explains

The stakes also are higher. “Whereas an external oil leak in an automatic transmission may result in a warranty issue,” Darling points out, “premature failure of the EV control unit can be catastrophic.”

The testing changes for the new repurposed system were relatively straightforward, but they required a lot of replumbing and a new process sequence. KUKA completed the update for the EV transmission program in about 12 weeks at one of its facilities in Michigan.

Future models could benefit from KUKA’s modular chamber design, which features removable panels that can be retooled.

Regarding leak testing, the first step when switching to an EV program is for the manufacturing engineering team to conduct a process capabilities

Educational Purposes

Making hardware changes is the easy part. The bigger challenge is transforming manufacturing cultures and getting people to accept that an EV gearbox is different than a nine-speed automatic, Parker explains.

“Do we really need to leak test parts to tighter tolerances? It can be a real learning curve,” he notes. “Everything leaks differently. We educate customers on leak-rate theory, how aluminum porosity leaks differently compared to leaks from welded joints or fastened joints.

“It can take time, but eventually there is an ‘aha moment’ when the customer realizes that a leak through porosity in a cast aluminum housing is different than a leak from a weld or a rotating seal, or that fine threads leak differently than coarse ones.”

There is also a teachable moment for helium-based leak testing. Helium systems are ideal for EV components, which have leak-rate tolerances that are as much as 30 percent tighter than ICE components.

Repurposing leak-detection systems for EV applications will be smoother for manufacturers that already have made the switch to helium on a traditional application.

During the process, Inficon also can provide suggestions on how to make the testing process faster with more repeatable measurements.

“Companies are finding that they can’t meet the tighter demands of an EV gearbox with pressure decay or air-testing systems,” Parker says.

A cost-saving option is to blend helium with hydrogen. The mixture is not as precise as pure helium, but it’s more economical. Inficon’s LDS 3000 can detect both gases.

Advanced test systems also can be integrated with emerging Industry 4.0 technology.

“Leak detection can provide important data to help companies identify potential quality issues and make more informed decisions,” Parker says.

For example, Inficon offers flexible bus modules and device-specific connectivity. That capability can be added during the repurposing process, which allows information to be shared with production equipment and operators to quickly identify potential problems and make changes on the fly.

“The more data you have available, the better it can be used,” Parker explains. “Leak testing is well-suited with Industry 4.0.”

Repurposing leak-detection systems for EV applications will be smoother for manufacturers that already have made the switch to helium on a traditional application.

Why It Matters

The transition to electrified drivetrains, which is well underway in Asia and Europe, is gaining momentum in North America. EV sales in the U.S. are expected to nearly double this year to account for 3.5 percent of the new-vehicle market from last year’s record of 1.8 percent, according to a recent IHS Markit forecast. EV market share is projected to hit 10 percent by 2025 and continue to grow through the end of the decade.

Parker predicts that repurposed leak-detection equipment will follow a similar growth rate. He estimates that there currently is the potential to retrofit about 100 systems in North America and some 1,000 globally.

“Right now, it’s all about getting up to speed quickly and being cost effective,” he points out. Long term, however, demand for new test machines will eventually outpace those of retrofits as new technologies are introduced.

“There are always benefits and tradeoffs to consider,” Darling concludes. “The key is to continue to improve. The only limiting factors are your imagination and determination.”

To save money on leak testing, engineers can opt to blend helium with hydrogen. The mixture is not as precise as pure helium, but it’s more economical. Photo courtesy Inficon

Editor’s note: Inficon has released a new 51-page guide to leak testing electric and fuel-cell vehicle components. The new e-book is available for download at: https://bit.ly/3sdRKxq. It covers leak-detection methods for a wide variety of applications, including battery cells, battery housings, electric motors, motor cooling circuits, sensors, control modules, fuel cells and hydrogen tanks.

ASSEMBLY ONLINE

For more information on leak testing, visit www.assemblymag.com to read these articles: