Manual Assembly

Matilda Wollter Bergman // Manufacturing Engineer // Volvo Cars // Gothenburg, Sweden

Managers should address the mental aspects of assembly work as much as the physical aspects.

Cognitive Ergonomics of Assembly Work

Work instructions ensure that assemblers follow standards. Photo courtesy Volvo Cars

While assembly work has always been physically demanding, little is known about the overall consequences of cognitive loading on assemblers’ performance, well-being, and the speed and quality of production. Cognitive under- or overloading can cause a lack of focus or distraction on one hand, or overwhelm on the other.

To learn more, we conducted a study to understand how work conditions affect cognitive demands and performance. Specifically, we wanted to learn the demands and resources that influence cognitive workload and performance in assembly work.

The study consisted of semi-structured interviews with 50 assemblers at three Swedish manufacturing companies: two automotive OEMs (Company A and Company B) and one automotive components supplier (Company C). The interviews were conducted individually at each company’s assembly plant. The workers represented a variety of experience levels, genders and ages. The questions were formulated to probe individuals’ work experience, understanding of their work tasks, what they perceived as enabling or hindering their work, and how the products or production tasks and work environment affected their ability to perceive signals, recall information from memory, solve problems and make decisions.

With few exceptions, all the assemblers worked on paced assembly lines with a specified takt time, which limited how long they could spend carrying out any assembly task. For most, the work day consisted of several time-limited rotations at a particular workstation, where they would perform assembly work from 20 minutes to a couple of hours, before switching to another station.

At the parts supplier, most products were similar and produced in batches. At the OEMs, each individual vehicle came with custom specifications that required assemblers familiarize themselves with how to assemble various options. This could involve selection of components and materials, dealing with packaging, moving objects from material racks to the line, and attaching components with one or more tools. Parts could be very heavy, occasionally requiring the use of lifting devices or pneumatic tools.

Despite the interview focus on cognitive loading, the interviewees emphasized that they considered assembly work to be much more physically than mentally straining. Most assemblers felt that assembly was manageable, and that the main challenge was exposure to heavy or repetitive physical loading, leading to fatigue and cumulative injury.

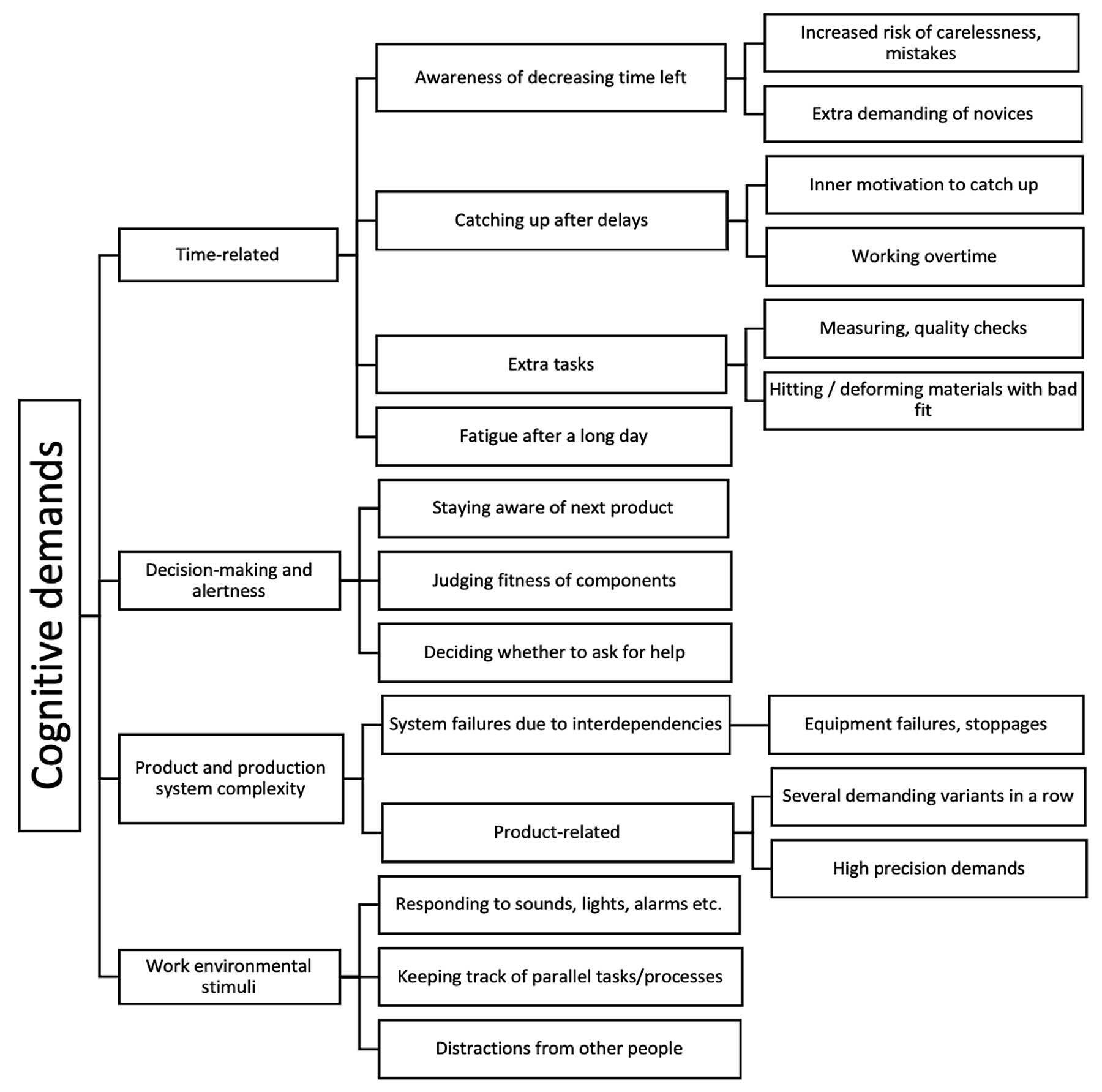

Cognitive Demands

The authors identified four main sources of cognitive stress on the assembly line: time pressure, decision making, product complexity and environment.Source: Chalmers University of Technology

We identified a variety of cognitive demands on assemblers. One of the biggest is time pressure. Assemblers are acutely aware of the time needed to complete a task. Indeed, in most companies, a visible clock is counting down the time to start assembling the next product. Cycle times at paced workstations vary from 1.5 to 7 minutes. Novice assemblers, in particular, viewed this countdown as a source of stress and a distraction from focusing on the work at hand.

At Companies A and B, the occurrence of product variants with unexpected assembly requirements was mentioned as having a large impact on the time needed to complete a task. The feeling of running out of time could cause one assembler to work more carelessly: “When you’re behind, mistakes come, because you more or less throw in the screws and washers,” reported one assembler. “Whether or not it’s the wrong way round, I have to hurry on to the next one.”

Time pressure is also related to production linr disturbances, such as a machine failure. The resulting delay could cause great frustration. Interviewees from Company C reported that they were motivated to catch up with the tempo after production problems occurred. Another assembler mentioned the occasional need to measure components, such as beams, to ensure tolerances: “Sometimes we have to measure beams, and that’s super complicated. You also have to build all the other stuff, too, with the clock ticking. It’s a thing you don’t want to do, start calculating math while you’re supposed to be building.”

In a worst-case scenario, activities that assemblers would need to fit into the available cycle time could include interpreting instructions, handling missing or faulty components, dealing with assemblies with poor fit, addressing queries from colleagues (or extending queries of their own), and generally needing to be quick-thinking and aware of what was coming next: “You always need to stay one vehicle ahead, in your mind, even as you’re handling heavy loads.”

Assemblers also mentioned that some degree of rapid decision-making was occasionally involved in the assembly, due to variability from the material and tools: “You get a piece that’s just borderline on whether it’s wrong, and you have to stand there thinking, ‘Should I do something about this, or not?’”

Environmental factors, such as noise or blinking lights, could also contribute to assemblers’ feeling stress and fatigue: “You get tired in the body and the head because of all the noise.”

At Company C, some signals could come from parallel processes that assemblers were expected to monitor at the same time as their assembly tasks: “It’s hard enough to keep your focus on a station when you know that at any time, this other station might start beeping. Sometimes it might not even beep, so you have to turn around and check that it’s running. That can be mentally demanding.”

Precision work was another product-related factor highlighted by interviewees at Companies A and B as mentally taxing, since it required thoroughness under time pressure. For example, components requiring high precision risked being mounted incorrectly and therefore require extra effort and time to correct afterwards. This problem could stem from ambiguous component design, faulty materials or tolerances that were difficult for assemblers to live up to without some kind of quality-assurance guide or tool: “When a connector or a screw or something that fits in several places can end up wrong and when there’s so much to keep track of, it’s easy to make a mistake.”

Interviewees emphasized that unclear work instructions can be very demanding: “It can be hard to know why a pipe should be rotated a certain way, because it’s not always evident from the instruction.”

Workers at all three companies reported that work instructions could be incorrect and contain a large amount of information that is demanding to read: “There’s a lot that isn’t right. There’s a lot of stuff to remember and rules of thumb. There’s also a lot of information like someone writing, ‘Note: assemble this.’ But texts like that, you stop seeing them after a while, so they just add to the disorder.”

At Company A, participants described “red stations” involving several demanding work tasks. These require help from another assembler, and no one is meant to work there too long. Workstations with too much or too little task variety that are poorly balanced could result in overload or underload: “Sometimes it can be very calm and very monotonous, because it is a very easy sequence. Then, you become rather understimulated. But, when there is a very high sequence, things can go the other way, meaning that it’s too much.”

Something that set Company C apart was that the complexity of its product was lower than that of the OEMs, so most assemblers reported that they found the cognitive load manageable. As one assembler described it: “I [have to] think quite a lot, but I don’t find it particularly straining. It’s just a responsibility, that I should do my part correctly. And instead of doing it wrong, I’d rather think about it for two seconds extra.”

At the same time, however, too-low task variation could also lead to negative attitudes towards the work: “Some days you think, ‘Well, here I am doing the same thing again.’”

Emotional Demands

The mental aspects of assembly work are just as important as the physical aspects. Photo courtesy Volvo Cars

Interviewees reported certain situations that involved emotional demands. Interviewees reported feelings of frustration or irritation after experiencing system or component failures that they had no control over—this frequently had consequences such as time delays and increased need for adjustments, staying overtime and additional physical and mental effort. Equipment failures, in particular, seemed to cause frustration, since assemblers would often have to wait for repairs before being able to resume work: “When machines don’t work like they’re supposed to, sometimes it takes a good while before they get fixed. And you have to stand there and fight with it. It gets pretty straining.”

Despite lacking control, assemblers still experienced a sense of needing to catch up. Alternatively, they anticipated needing to work longer hours or work on weekends to meet production targets, a common source of dismay. Similar frustrations could come from assembled products not passing quality checks, which routinely required adjustments.

The products themselves could cause emotional responses, particularly when assemblies were difficult and several of them occurred in succession. One assembler at Company B said that “We had really difficult vehicles last week, and we were behind all the time. Invariably, you would find out that you made a mistake five vehicles ago, and you would wonder, ‘How did that go wrong? How did I manage to do that? It can’t be right,’ You go into denial. And then you try to concentrate even harder, even though you know another car is coming. So those days, you absolutely just want to go home as soon as possible.”

Assemblers also mentioned the emotional toll of combined physical and mental fatigue after long working days. This was particularly tangible if they were asked to stay overtime. Some felt additional frustration at knowing that certain tasks would regularly require them to handle heavy loads. It appears that due to the predominantly physical nature of the work, it was hard for the interviewees to disregard its effect on mental performance entirely when they were asked about the work being mentally strenuous. The body-related aspects came up as dominant in their experience of the work.

One assembler described how some components would not always fit well into assemblies with narrow tolerances, leading to frustration and extra physical efforts to force them in: “They can be pretty badly fitted, so you really have to bang on and bend them. They’re hopeless and they give you trouble.”

The same assembler described a variety of sources of frustration and confusion, such as unplanned staffing changes, material being kitted incorrectly, and special-operations assemblers showing up to workstations without warning and imposing their notes and instructions.

Frustrations often arose from lack of communication: “If the communication isn’t good, if you don’t get informed in good time so you can prepare yourself—that can be frustrating.”

Some frustrations could arise from colleagues getting in each other’s way, particularly when working faster than the assigned pace: “That person hasn’t understood why he causes irritation. It’s because the other person has to wait, even though their time hasn’t started. This makes some people really mad while others don’t care. But of course, I can get annoyed, too, if someone doesn’t move and makes me wait.”

Similarly, frustration could arise from a perceived lack of understanding from other parts of the production chain: “It’s frustrating when decision-makers don’t listen to workers. Often, it’s a seller who has said [to the customer], ‘You can have that in your vehicle, no problems,’ but the wire harness has already been made and there aren’t any wires for that button, and then it becomes my problem to add those wires.”

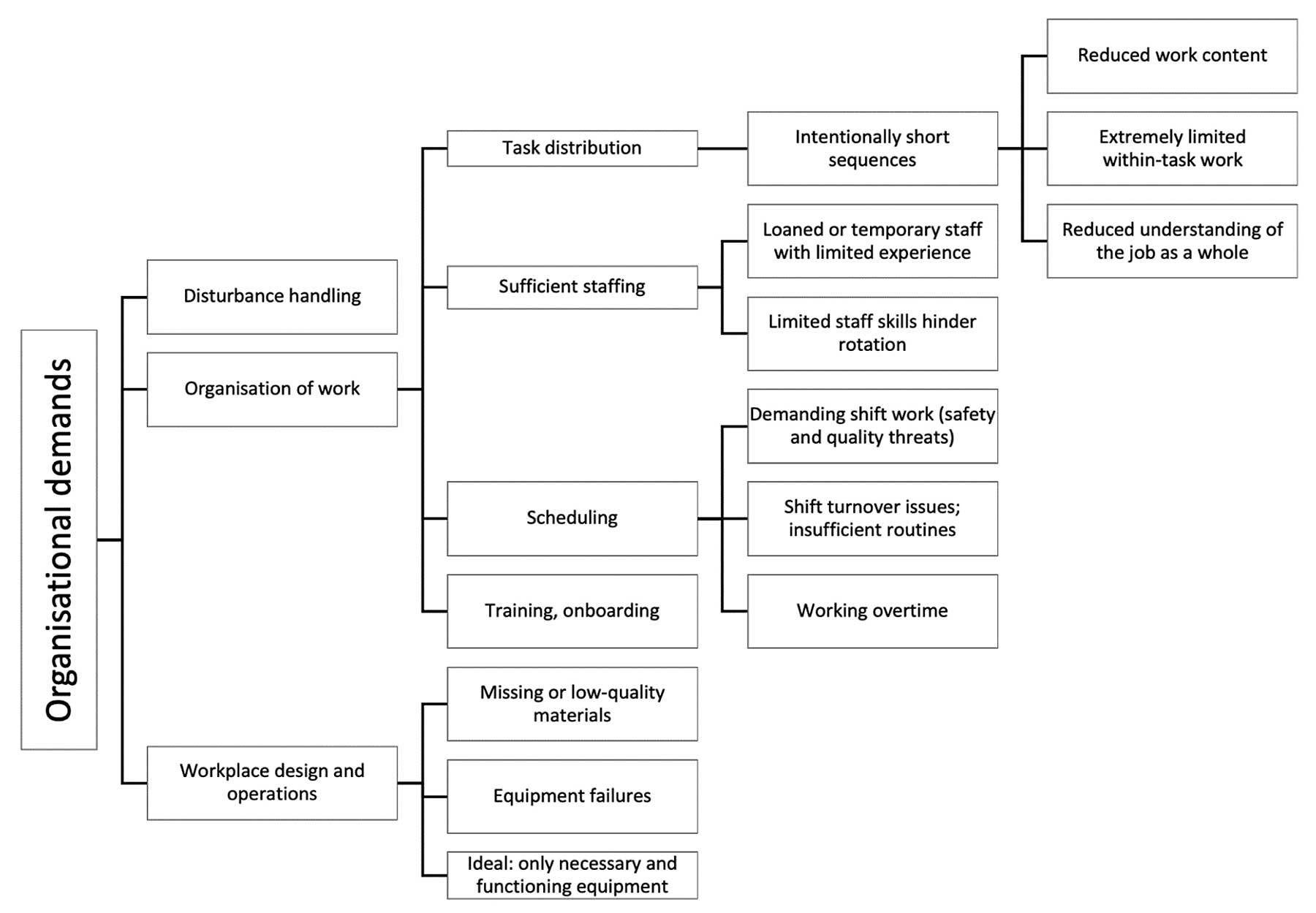

Organizational Demands

A variety of organizational resources can help mitigate mental strain on the assembly line. Source: Chalmers University of Technology

Demands resulting from the organization, scheduling and design of work were exemplified in several ways. In all three companies, it was common practice to lend operators from other lines to cover gaps and provide enough staff at each line. However, this required a lot of effort to uphold workflow and affected group dynamics negatively: “If we get someone from another line, who hasn’t been in our group and doesn’t know how we sync, then it gets a bit choppy.”

Sometimes inexperienced staff could add a limitation that affected the variation for the entire team: “When people are sick, we staff with people [from the temporary staff pool] who know several different departments, so they most often only know one or two stations within our department. So that person gets locked in, and we can’t rotate around, so maybe everyone has to stand still. This causes [people to get] irritated.”

Some interviewees who had experienced being “lent out” to an unfamiliar station described that it could be demanding (but stimulating) to learn new things, while others felt that they were learning new things constantly, partly because of occasional changes in operations. Getting accustomed to the new tasks often involved them asking more questions of surrounding colleagues to verify that they were assembling correctly.

Regarding onboarding, interviewees appreciated standardized routines and more practical rather than theoretical approaches for learning new assemblies. However, at Company C, one interviewee who had been working the night shift during his onboarding process described how his introduction had suffered from a lack of structure and coordination, which made it hard for novices to learn: “The supervisors were going to teach us and were running between us. They were very skilled, but they weren’t on the same page. So one came and said, ‘This is how you do it,’ and then after two days, the second one came and said ‘What are you doing? You can’t do that!’”

A common practice was to standardize work tasks and reduce them to a shorter sequence with fewer steps, to ensure quality and to ease the onboarding process for new staff. However, it had an adverse effect as the operators’ motivation decreased and they felt disengaged towards their work instead. For example, one experienced assembler said that he felt “limited when you’ve worked as long as I have. We [previously] had a completely different kind of assembly. So, I can’t say it’s gone in the right direction, certainly not. What I miss is the whole picture, now that I just do one part. You don’t get the same holistic view, so to speak.”

Some interviewees felt that there were limited opportunities offered at their company to develop new competencies on the job.

Unexpected events were a frequently reported issue that assemblers said affected the workflow. Several assemblers felt that it would be desirable to have better preparation to handle disturbances, and to reduce risks for unexpected events. Some assemblers stated that a combination of having enough time to complete the task, and to have been given enough time to become well-trained to perform the task (particularly new ones), were conditions that supported a good flow.

Workers reported that there were gaps in their routines for ending a shift, which delayed and increased their efforts towards preparing their shift start-up: “If there’s been an issue with the previous shift, they can’t focus on how to turn it over to us. It’s the same for us. If we have a problem at the end of the day, then it might not give the right starting conditions for those who start in the evening. We might leave it a bit badly done because we haven’t been able to focus on it”

“They care about doing their thing, but not about the one coming after,” added another assembler. “Sometimes you have to refill your own material, and then it takes a few minutes before I can start.”

Shift-work itself was recognized by participants as taxing and unfavorable to safety and quality: “Shift-work creates tiredness and can lead to assembly mistakes or injuries.”

Regarding the design and operation of the physical workplace, participants described the effects of late deliveries or inadequate quality: “Material handling doesn’t work very well, so we have to hunt for material.”

Other reported issues were faulty materials, ill-fitting parts, and inadequate supplies. At Company C, half the interviewees stated that equipment quality greatly impacted workflow. Another issue at the workstation level was when instructions were difficult to understand or not updated.

Social Demands

Cognitive under- or overloading can cause a lack of focus or distraction on one hand, or overwhelm on the other. Photo courtesy Volvo Cars

Regarding working with other people, the assemblers mostly emphasized how social interactions and teamwork were a strength, but demands appeared mostly due to unfavorable group dynamics, interdependencies between individuals, and dealing with other people as a distraction.

Group dynamics was recognized by interviewees as influencing cognitive workload—particularly, a dysfunctional work dynamic could result in dissatisfying teamwork and lowered motivation to come to work: “If there’s a bad vibe, of course it’s not as fun. It’s not as rewarding.”

At Company C, a lack of collaboration and communication could, for example, lead to colleagues not helping each other refill materials. One assembler described that the social interaction of doing the right thing towards colleagues and making them feel at ease was key to achieving good workflow.

At Company C, interviewees mentioned that having a production target for the team was demanding; often they would try to work faster than the set pace to reach their target. However, different assemblers had different capabilities to work faster than that pace, which could contribute towards a dysfunctional group dynamic: “Some people feel that we need to reach our goal despite a few slower workers, and that often leads to tensions because then it’s one or two people chasing that goal.”

Making mistakes added social pressure since they could add to the overall workload, leading to overtime for everyone. All three companies had tracking systems that allowed a mistake to be traced to a particular individual, which added a sense of being watched and held accountable. Some assemblers described this “blame culture” as a social pressure on them. Assemblers could also experience negative effects of being dependent on each other’s performance; receiving incorrect assemblies from earlier stations could add to a collective sensation of failing to carry out the task correctly, leading to everyone being negatively impacted by the need for adjustments and overtime.

Individual Preconditions and Attitudes

One of the biggest mental challenges of assembly work is time pressure. Assemblers are acutely aware of the time needed to complete a task. Photo courtesy Volvo Cars

Most assemblers were aware that each co-worker had individual needs, assets and motivations, and that it was important to be prepared, trained, equipped and motivated to assemble correctly. While many of these aspects could be viewed from the resources perspective, some intrinsic job demands were mentioned by the interviewees.

One interviewee reflected that even though he personally felt motivated to push his own performance, he was aware that “colleagues who maybe have kids and can’t work overtime so much, they work to a different effort level and reach their targets all the same, but I like maximizing and pressuring [myself].”

Conversely, when assemblers felt decreased motivation and negative attitudes towards work, it could result in bad assembly, characterized by “doing sloppy work, with no overview of what you’re doing. Or you work too fast and in a way that is harmful.”

Many spoke of different kinds of musculoskeletal disorders that they expected to become more sensitive to with age, and certain interviewees were concerned for their younger colleagues’ future well-being: “Some have worked for 15 years in assembly, which isn’t that usual, now that the [pace] is the way it is. But they work in a way that assures that they will last. They work calmly and methodically. While the young are more, everything has to go so fast, and preferably with a bit of movement. When fetching stuff, I take that extra step when I pick something up. While the young think, ‘I’m young, this won’t hurt me.’”

Several interviewees believed that the work pace was too demanding for an entire work life. This was one decisive factor for many in considering quitting their work as an assembler: “After 15 years, you start getting tired of this, so maybe one should try something different. If you think that, yeah, you’ll work until 67, it’s a long time and it’s quite tough. It can be. Because it’s the line, and the tempo is high.”

In addition, interviewees mentioned that the work is both cognitively and physically demanding, making them tired after a working day: “I’m tired when I’m done, but it’s physical too, not just psychological.”

Interestingly, when the assemblers were asked about aging, several mentioned that their current older colleagues (ages 40 to 55) appeared to be doing fine, particularly if they were experienced and had been assigned less strenuous stations. However, many were concerned that their own bodies would not be able to withstand the physical loading, high tempo and “running around” until retirement age.

For others, a lack of personal interest or motivation, or wanting to reduce future exposure to the constant time pressure, was their main reason for believing they would not want to stay. Among those who believed that it would be possible and desirable to continue working until retirement, they mentioned how the “calm” and routine that comes from experience would make it possible—as long as the cycle time did not become shorter in the future.

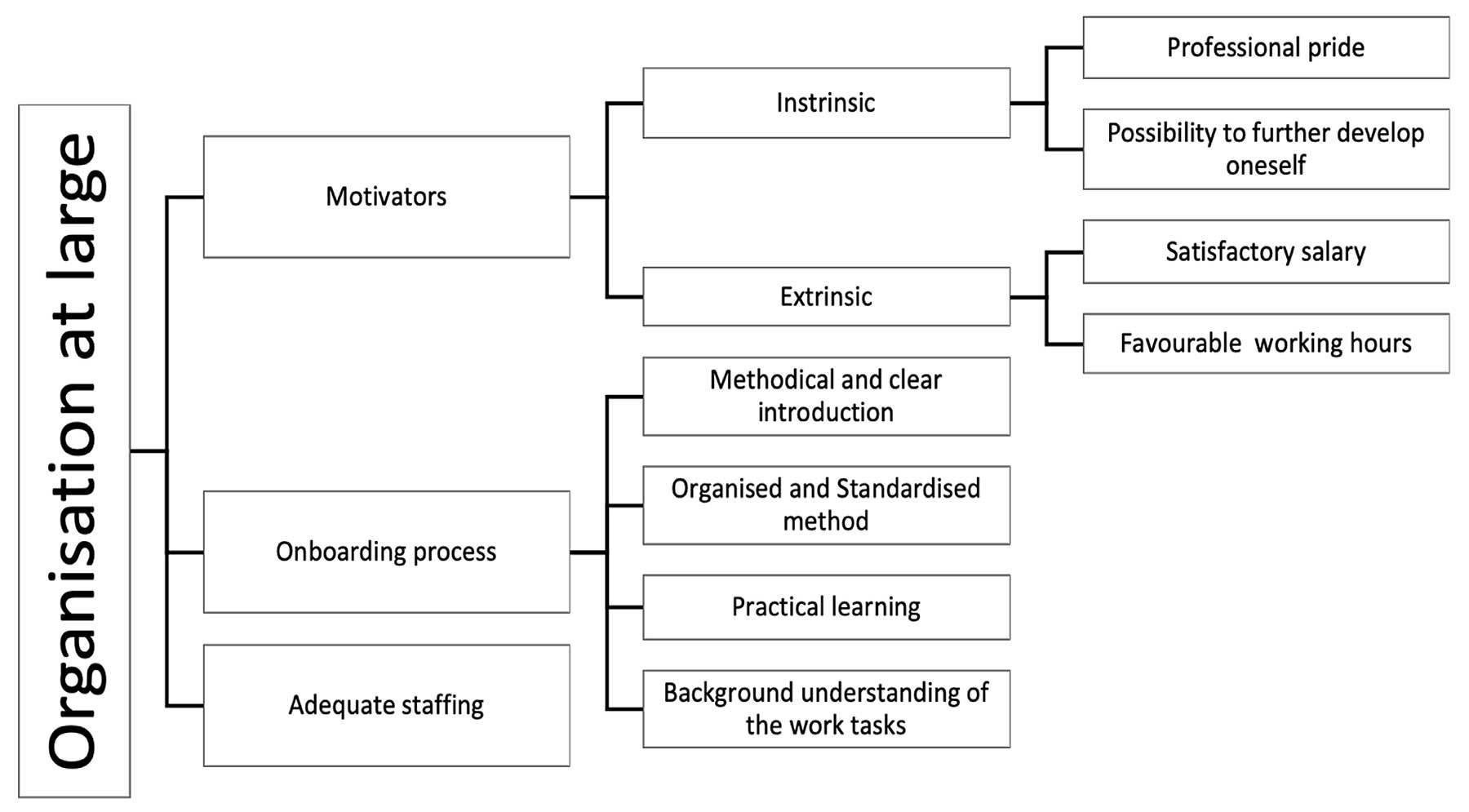

Organizational Resources

A variety of organizational resources can help mitigate the mental strain of working on an assembly line.

Regarding the organization at large, motivators, the onboarding process and adequate staffing were identified as the main resources. Workers' performance was influenced by their intention to continue working as an assembler, which was steered by a set of intrinsic and extrinsic motivators. The intrinsic motivators included the perception that the task itself is important, resulting in positive emotions, while extrinsic motivators included rewards for good work.

Four motivators were identified: two intrinsic (professional pride and possibility to develop oneself) and two extrinsic (satisfying salary and favorable working hours). According to the interviewees, these motivators contributed to enhanced engagement as well as inner calm and thereby lowered cognitive demand. The intrinsic motivators were similar among the three companies.

According to the interviews, professional pride is enjoying the work tasks, taking pride in assembling with quality and the feeling of being skillful when performing the work: “It is fascinating to see what we are achieving and contributing to.”

Knowing that one is good at performing one’s work also increases self-confidence and contributes to reducing nervousness over making mistakes: “I like monotonous jobs, I am rather good at doing such things all the time, because I like it. I love working in assembly.”

Moreover, the possibility to develop oneself and learn new things was important for work performance and increasing engagement: “As I am very invested in my work, I think it’s fun, and I want to learn new things.”

Other examples were providing the opportunity for assemblers to challenge themselves, through involvement in problem solving or receiving a promotion. It was also emphasized that work created positive emotions such as joy towards their work: “I am rather involved in all the improvement work at our department, so I am keen to identify problems as well as solve them. I find it enjoyable and stimulating.”

Regarding the extrinsic motivators, both satisfactory salary and favorable working hours influence work performance positively. As workers were rewarded, they became more engaged in their work.

The onboarding process for introducing work tasks was also mentioned, since it affects the operators’ ability to handle their work later. A common factor that was considered to influence the participants’ learning was having tutors that introduced the tasks methodically and clearly described the working steps to provide the assembler with sufficient time to practice: “We should follow a certain pattern that we are confident is the smartest and smoothest way to learn. I believe that the most important thing is to have time to learn to not feel any stress but to take it at your own pace.”

Having a short task reduced the amount of training needed by assemblers, which could in turn ensure product quality. The participants at Companies B and C mentioned that having the same tutor was important for continuity. In contrast, participants at Company A mentioned that having different tutors was favorable, as taking part in different operators’ working methods helped them to easily find their own working style: “We have a standard procedure that we follow, but there are some things that are not written down exactly how to do it, since everybody has their own personal way of doing things. We try to have one [tutor] in the beginning and one in the end since both work differently, so the person learning can have the best of both.”

At all three companies, the interviewees emphasized the importance of offering new operators the same learning conditions. They expressed appreciation for supervisors who used an organized and standardized onboarding process to introduce tasks to new operators. Participants at Companies B and C also emphasized the role of a practical learning method that included assembling under the guidance of an experienced operator. Additionally, the interviewees described that giving the operators a deeper insight into the entire product and a background to why the working steps are designed in a certain way, facilitated their learning ability: “Those who have been on the main line for a while and have seen how they build have a better understanding for why we assemble things in certain ways and then also assemble better. They can tell when the specifications are wrong.”

Adequate staffing, training and motivational factors can help assemblers feel less pressure on the line. Source: Chalmers University of Technology

Providing operators with these resources during introduction fostered skills and resulted in becoming confident in performing the work, thereby lowering cognitive load: “I feel that I could even help [others] if necessary.”

Besides the introduction, the participants also highlighted that they were provided with opportunities for skill development through courses such as ergonomics, material training and machine training.

Adequate staffing was also emphasized as a resource: “Sometimes we’re just five on the line, sometimes maybe six. It depends on how the job should be done, to have the best flow.” Having enough staff enabled the operators to successfully perform the assigned tasks as they were described to promote workflow and mitigate cognitive strain.

With regard to organization of work, three themes were identified that directly and indirectly affected cognitive demand. Participation in decision making was mentioned as crucial, since the operators themselves often had ideas about how to optimize their workload. The interviewees highlighted different approaches for a successful involvement of operators in decision making. One common practice was using continuous improvement to develop the work together with the operators: “Everything is standardized, but if we have a suggestion, I tell everybody at the meeting, ‘I have this suggestion, what do you think?’ If it’s a good suggestion that saves time with no additional risks, then we go ahead.”

Continuous improvement consisted of regular meetings where workers and managers discussed improvement proposals or wrote down ideas and thoughts: “Once a month we have something called continuous improvement, where we write down ideas and thoughts that we later share with our shift supervisor.”

Another common practice was communicating suggestions directly to the shift manager or writing them down on a whiteboard. Interviewees at Companies B and C presented improvement proposals straight to technicians in the maintenance department. Company A assigned operators with improvement responsibilities, which they were obliged to follow up and time was set for each operator to carry out the improvement work: “We have development targets that everyone is given time to work on. Some people are what we call brainstormers. They have a lot of ideas. During assembly, they might say, ‘Can we do it this way?’ So that one feels involved, which I think is important.”

Improvement proposals were handled in different ways. For example, work instructions were developed in collaboration with the operators: “There are binders and instructions for every workstation. These are formed together with our opinions. So I think these are as good as can be.”

Outdated work instructions required more effort to read and contributed to confusion. Improving them on a regular basis can diminish the risk of uncertainty. Participants at Company A mentioned the ability to influence the sequence of work tasks, which improved performance and workflow. Additionally, interviewees described that having a supportive management team and receiving feedback on their improvement proposals encouraged taking part in decision making and facilitated performance.

Providing operators the possibility to influence work planning was also described as facilitating performance and reducing cognitive workload. For example, unwanted stress could be prevented by letting the operators prepare in terms of loading material and checking that equipment is functional before assembling: “I often try to start working a little before the line starts. I start planning and do it now instead of later when it becomes more stressful. I prepare tools and order parts that needs to be brought via forklift from supply.”

Another example mentioned at Company C was the possibility to plan work to achieve the production goal and simultaneously reduce stress: “Sometimes we agree to work quickly the first four hours before lunch to avoid stress at the end of the day, because we have a production goal, and we need to reach it.”

Manageable product variability was identified as important for creating workflow and mitigating cognitive overload. As companies mostly had moving lines with products of a certain variation, the degree of difficulty varied: “I think it is good with a little variation, but when it is too much up and down, it is not so good. When it’s a bit calmer, and then a bit harder, one stays active.”

Participants described that product variability should be distributed evenly to avoid peaks of demanding assembly: “You feel how your energy drops faster if there are many difficult cars at the same time during the whole day, instead of being spread out so that we don’t have to feel that stress.”

Design of the work environment was emphasized as a factor that contributed to reduction of cognitive demands. Interviewees mentioned that having quality materials delivered on time was important for creating workflow and reducing disturbances: “When the material is in place, everything flows.”

Having materials at the right height enabled easier movements: “We had a colleague who sat and thought for a long time about how we could place the material in a way that would make it easier for us to assemble. It revolutionized our way of assembling.”

In addition, having only necessary and functional equipment on the line was found to be beneficial: “When the line works as it should without technical problems, there is automatically a decent flow at the line.”

At the task level, five factors were identified that facilitated the operator’s performance. A well-balanced and well-planned workstation enabled a sense of calm and the feeling of having enough time to perform the task. Overloaded workstations could result in stress and operators taking shortcuts that could lead to injuries and faulty assembly. Sufficient time to complete the work was considered crucial: “Good assembly means that you have enough time. Everyone has an inner calm, and the pace is not so overwhelming. When you feel that you cannot keep up, you start taking shortcuts, and shortcuts entail risks.”

Minimizing work disruptions was essential for reducing cognitive workload: “I think that the work flows well when we aren’t having any stoppages.”

Some participants found anything outside the standard of work to be a distraction: “Everything beyond the standard takes extra time and creates more stress.”

Task variety was mentioned in all three companies as important. To avoid the feeling of monotony, variation in the tasks was vital: “We perform many different tasks at each workstation, so we don’t get [the situation] that it becomes monotonous because you stand and do the same movements all the time.”

Frequent work rotation can have a positive influence on performance: “Good rotation, so that despite a high pace after a while, half an hour, you can do something else.”

Frequent work rotation during a shift was important to uphold the assemblers’ focus and stimulation: “Just to give the brain a different stimulus.”

However, rotation frequency differed between companies and within companies. At Company A, it was described that the rotation frequency depended on whether colleagues knew the tasks at the workstation or not: “We try to rotate as much as possible, but not everyone knows every station, so some of us need to skip it.”

According to participants from Companies A and B, creating simple assembly tasks was important. By enabling the operators to easily identify where to mount components enhanced their work performance, as having precision demanding work tasks required heightened effort: “The optimal way is being able to directly visually see where everything fits, then one doesn’t need to think about if it should be mounted here or there.”

Social and Interpersonal Resources

Error-proofing technology can help ease the mental strain of assembly work. Photo courtesy Volvo Cars

Good social relations foster enthusiasm and a positive work environment: “Colleagues—that’s why we’re here; everyone is nice.”

Collegial cooperation and cohesion facilitated workflow, increased motivation and mitigated cognitive workload. Fellowship between colleagues was described as a factor that led to good group dynamics and good communication that also increased motivation for being at work. Social contribution led to a positive attitude and good performance. Participants said they had fun working together: “I enjoy being with and having fun with my colleagues. We do our work, but also joke around.”

A well-coordinated team also enabled workflow: “We have a good team. Everyone does exactly what they should so we get a good flow.”

Asking colleagues for help is another resource: “When you see the component, you know that it should fit somewhere, but to double-check, I usually ask someone with more experience.”

Several interviewees preferred consulting a colleague to reading instructions: “I’ve never had to use them, usually it's just faster to ask someone who knows, rather than go and read it.”

Reminding each other to avoid incorrect assembly was mentioned as a frequent behavior: “I’d rather ask than make mistakes. People are very good at this place. If someone notices that you made a mistake, they tell you.”

Moreover, some interviewees said that working faster than the predetermined pace enabled them to assist colleagues: “If you keep it up, you can finish your task and thereafter help others. I have a very good work team who help each other.”

Companies A and B had a support system, called andon, that assemblers could use to receive help: “I do not always remember when something appears wrong. There are so many different faults. We have andon in all departments.”

All three companies have personnel resources at standby to step in and assist with demanding tasks: “There is either an andon or a team leader at standby and ready to help if needed. We place them in positions to support us if things get rough.”

Cognitive Support

Components requiring high precision risk being mounted incorrectly and therefore require extra effort and time to correct afterwards. Photo courtesy Volvo Cars

Different types of support were identified to facilitate cognitive performance. Notably, these were perceived as satisfactory by interviewees in all three companies: “I often think they are very good as they are. It is very important that they exist if you are insecure.”

Several types of memory support were used to assist operators in preventing incorrect assembly. For instance, visual signals indicate if the assembler has performed the work step correctly or in the correct order: “You can see on the computer which step you should do next. And for example, if you forget to tighten a screw, the computer shows red. The same goes for the electric screwdriver. It has lamps that indicate if the screw is tightened or not.”

Similarly, pick-to-light systems indicate which component to assemble and when.

At Companies A and B, participants described that markings such as arrows or colors were used to facilitate assembly: “We have screws of different length, and they are color-coded.”

Another memory support mentioned at Companies A and C was a quality alarm, used to detect incorrect or unperformed assembly tasks by hindering the moving line, thus preventing the operators from continuing assembly: “The system will not let you go ahead with the sequence if you don’t finish a certain task.”

Each company used different kinds of memory support that were unique. At Company A, for example, bar code scanners were used to help assemblers remember which parts go with which variants. Another memory support used at Company A was a type of screen that prompted the assembler on how to complete various tasks: “Screens tell you when you are finished by turning green. Then the task is checked off and the line continues.”

Pre-kitted boxes with parts necessary to complete an assembly was an appreciated resource at Company B. The kits helped both in terms of knowing how to place components and ensuring that the correct number of components were mounted. Computers were used to assist in detecting electrical errors: “We have a computer that scans for electrical problems, so often we get a printed document from our colleagues at the line showing what is wrong.”

Vision systems were used to assist in finding errors and alert the personnel at Company C. These could detect most errors: “It’s difficult to get anything wrong, because we have these cameras that monitor the process.”

Another cognitive support was work instructions, presented on paper or electronically to refresh the assemblers’ memory. Having work instructions ensured that operators followed the standards: “We have everything documented in binders at each station, describing the work method that we follow. It doesn’t matter if there are ten different assemblers, they should all do work the same way. That is how we are trained.”

The interviewees also described that work instructions should be precise and easy to read. All companies had several kinds of instructions where the level of detail varied as well as the format: “There is a binder with different standardizations on what to do. There are pictures of the models from above, from below, from the side.”

The instructions were developed to accommodate even inexperienced assemblers: “It should be possible for people who don’t know how to read these and be able to build afterward.”

Individual Resources

Environmental factors, such as noise or blinking lights, can contribute to assemblers’ feeling stress and fatigue. Photo courtesy Volvo Cars

Individuals themselves can also influence their ability to handle the workload: “If you can work more efficiently, you do it.”

Level of experience was mentioned in all three companies as impactful on work performance; interviewees expressed how feeling relaxed and being skillful while assembling contributed to workflow: “I very seldom feel that I have to hurry. This has a lot to do with experience. One feels rather relaxed. You know exactly where everything is. I can almost stand there and close my eyes and assemble nowadays.”

Being focused and having the mindset of trying to assemble with as high quality as possible was another common factor affecting the assemblers’ performance positively: “A good assembly, that is essentially doing your best in the time you’ve got.”

Participants also described that taking time for self-checks enabled them to avoid adjustments requiring extra effort: “You should check the car after assembling; then you can find those errors.”

Memory training was identified as facilitating performance as it mitigated cognitive overload: “When I stand at the workstation, I no longer think, I just work. I have trained my muscle memory and it sticks.”

Interviewees mentioned that finding routines enabled them to incorporate their skills: “Foremost, you find routines. That this is my way of working at this workstation and then you always follow the same pattern, and then it becomes part of your muscle memory.”

Interviewees at Companies A and B highlighted that writing down notes was helpful: “I also have a notebook, otherwise you cannot remember everything.”

Practical Implications

It’s vital that work instructions be brief, accurate, and up to date. Photo courtesy Volvo Cars

A clear implication from this study is that no single role or stakeholder in a manufacturing system bears sole responsibility to address the problem of mental workload. Because the problem is systemic, so must be the solution. Potential for improvement exists at both the micro and macro levels. The resilience of the entire system can be reinforced both with individual-focused interventions, such as training and skills development, as well as through systemic characteristics, such as workplace design, organizational structures and beneficial collegial interactions.

The responsibility for identifying cognitive demands at various levels in the organization and addressing them should therefore be distributed across many roles. Early phases of product and production design, where design and manufacturing engineers are involved, are the most optimal and cost-effective stages for proactive ergonomic action. However, these interventions have predominantly focused on the physical demands of assembly, rather than the mental ones. It is our hope that the demands and resources outlined in this article can be used both for reactive and proactive intervention.

Manufacturing engineers and managers should also bear in mind that mental workload problems are a moving target. Assemblers often find individual or collective strategies and “tricks of the trade” to meet those demands. However, relying entirely on individuals’ capacity to cope with demands may be a slippery slope: Companies should avoid the detrimental trade-off where assemblers sacrifice long-term well-being, safety, engagement and motivation to “get the job done” in the short term. Their perseverance, coupled with dissatisfaction, is conducive to wanting to leave the profession as an assembler, which is a cost and a knowledge loss for companies.

Editor’s note: The following also contributed to this article: Cecilia Berlin, Ph.D., associate professor of design and human factors at Chalmers University of Technology, Gothenburg; Maral Babapour, Ph.D., project lead, Institute for Stress Medicine, Gothenburg; Ann-Christine Falck, physiotherapy manager, Västra Frölunda Specialist Hospital, Gothenberg; and Roland Örtengren, Ph.D., professor of ergonomics, Chalmers University of Technology.

This article is a summary of a much longer research paper. To read the complete paper, click here.

ASSEMBLY ONLINE

For more information on ergonomics, visit www.assemblymag.com to read these articles: