MAY 2023

MOTION CONTROL

What’s New With Conveyors

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

What’s New With Conveyors

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

John Sprovieri // Chief Editor

Transportation—moving parts or assemblies from place to place in a factory—is one of the seven wastes specified in the principles of lean manufacturing. Transportation does not add value.

That does not obviate the need for conveyors, however. These machines remain essential for getting the right parts to the right spot at the right time. Here’s a look at the latest offerings.

Ultrasonic Welder Assembles Medium, Large Parts

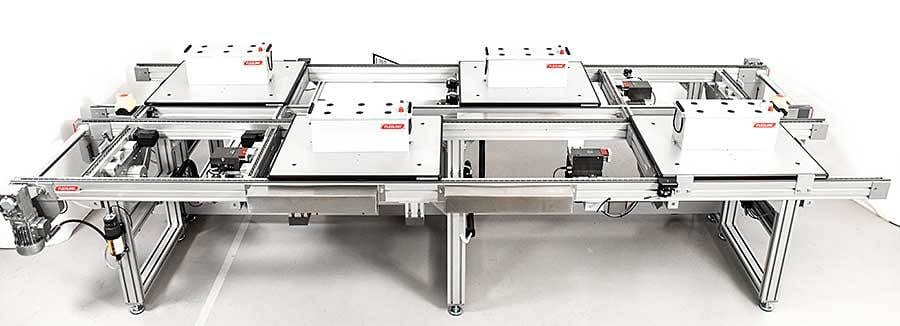

The HU twin-track pallet conveyor from FlexLink Systems Inc. is suitable for assembly and test processes for heavy loads. Configurable standard modules allow engineers to quickly and easily create layouts for routing, balancing, buffering and positioning pallets. Modules include predefined control logic, which reduces programming time and enables true plug-and-play integration. Functions such as transfers, locating stations and stops are all electrical.

The conveyor is fully digitalized and prepared for IIoT and traceability requirements. The software includes tools for pallet routing, traceability, data acquisition and OEE data.

The conveyor beam is rigid, ensuring smooth running with low noise. T-slots ensure easy but firm attachment of accessories. The upper slide rail is made of stainless steel, while the lower rail is made of plastic. The return chain runs within the beam. Three types of chain are available: steel roller chain, steel off-set roller-top chain, and lubrication-free steel roller chain.

Aluminum pallets come with an electrically conductive frame and are RFID-ready. The pallet has an accurate fixture interface and is tooled in relation to the locating holes. Standard pallet width is 1,040 millimeters. Conveyed products can range from a few grams up to 200 kilograms in weight.

A booster section doubles transfer speed when needed and reduces pallet exchange time by up to 50 percent. This reduces noise and stress on wear parts. Maximum speed is 15 meters per minute. Maximum conveyor length is 10 meters. Maximum accumulated load is 1,000 kilograms.

The conveyor has a mean time between failures of 12,000 hours (two years in a three-shift operation). All functions are plug-and-play and mounted in fixed positions, allowing a single digit mean time to repair. Smart motors and digital chain slack detection permit predictive maintenance.

A fully electric transfer is designed in two sections—lift and drive—to facilitate installation and maintenance. The locating unit stops the pallet and positions it with a repeatability of ±0.1 millimeter. The locating pins are situated on one side, but machined in the same piece to achieve perfect accuracy.

The system offers a range of stops and dampers. Stops can be electric or pneumatic. FlexLink also offers a unique gravity damper that gently slows down the pallet.

Smart asynchronous motors only run when needed, and thanks to the conveyor’s low-friction design, engineers can configure longer sections per drive. This reduces torque by 50 percent. Motor control can be integrated or separate. A chain tensioner with a proximity switch for alarming is optional.

Modules include FlexLink standard controls logic. The line controller manages routing and track-and-trace, while FlexLink device controllers manage sensors, functions and smart motors. The benefits are reduced PLC programming and fast reconfiguration of a system.

FlexLink offers a range of software applications for designing smart production flows. Material flow and process traceability are easily configured. The software also includes a production monitoring function for OEE improvements and predictive maintenance.

The FlexLink Design Tool permits quick design and line simulation, helping engineers to identify bottlenecks and verify new line configurations and OEE. The tool reduces engineering errors, saves time and allows quick and trouble-free order handling.

For more information, click www.flexlink.com, or visit the company’s booth at The ASSEMBLY Show in October.

The HU twin-track pallet conveyor handles heavy loads. Configurable standard modules allow engineers to quickly and easily create advanced layouts. Photo courtesy FlexLink Systems Inc.

Module Gives Conveyor A Boost

Ideally, engineers would like to minimize the amount of time spent moving product from one assembly station to another. However, that’s not easy to do with a belt-driven pallet-transfer system. Every pallet riding on the belt travels at the same speed.

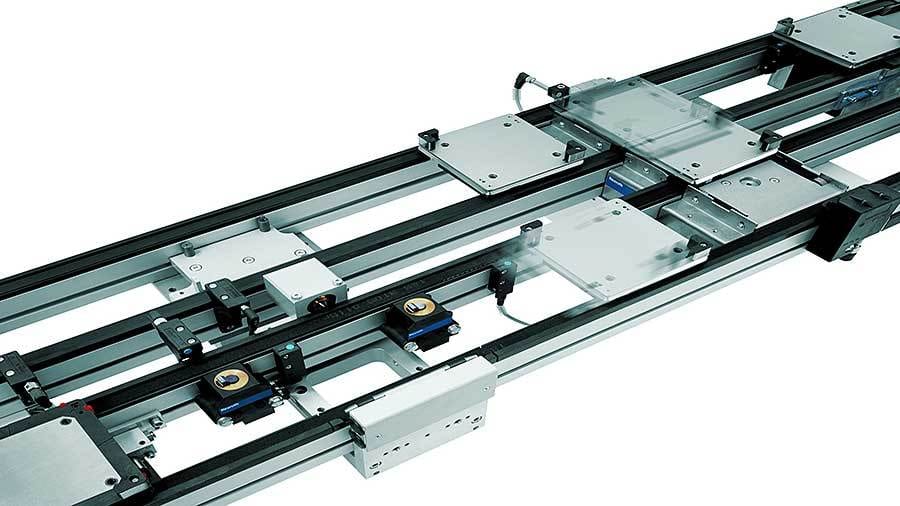

To address that problem, Bosch Rexroth has introduced the pallet booster module for its TS 2plus twin-belt pallet-transfer system. Instead of belts, the module is equipped with a short length of linear motor that rapidly, but carefully, moves pallets past unproductive space on an assembly line. Depending on the application, it is up to ten times quicker than standard transfers.

The standardized, preconfigured module is designed to accept and hand off pallets to and from sections of TS 2plus conveyor. Maximum acceleration is 4 g, and maximum speed is 4 meters per second. It can accommodate pallets ranging from 160 to 640 millimeters long and 160 to 400 millimeters wide.

Bosch Rexroth has introduced the pallet booster module for its TS 2plus twin-belt pallet-transfer system. Instead of belts, the module is equipped with a linear motor that rapidly, but carefully, moves pallets past unproductive space on an assembly line. Photo courtesy Bosch Rexroth

The module can do more than just move pallets quickly. It can also position pallets precisely without additional indexing. No additional positioning unit or handling system is necessary. And, since it’s a linear motor, pallets can move in either direction. The module can even be used as a precise motion control system. For example, the module could move a pallet beneath a stationary dispensing valve, obviating the need to mount the valve on a gantry system.

The TS 2plus conveyor is designed to transport pallets up to 240 kilograms. It features standardized modular units that can be combined in many ways to create a single system. The modular design permits the cost-effective use of ratio potentials in production. The system’s three-phase motors are energy efficient.

The conveyor can be used in static-safe environments, clean rooms and dry rooms. Pallets range in size from 160 by 160 millimeters to 1,200 by 1,200 millimeters. Conveyor speed ranges from 6 to 18 meters per minute. Four types of conveyor media are combinable as needed: polyamide belt, toothed belt, flat-top chain and accumulation roller chain.

Accessories include lift-and-transfer modules, electric stop gates and dampened stop gates.

For more information, click www.boschrexroth.com, or visit the company’s booth at The ASSEMBLY Show in October.

Conveyor For Short Cycle Time Operations

The Modu-Con 6 from Automation & Modular Components is a twin-strand pallet-transfer conveyor for the automotive, appliance and electronics industries. It is the company’s fastest conveyor, with speeds up to 200 feet per minute, thanks to a pallet that travels at 2.5 times the speed of the chain. This makes it ideal for short cycle lines and transfers.

Pallet sizes range from 20 to 48 inches wide. Transfer media can be either plastic chain or clean-room-compatible, nickel-plated steel roller chain. The conveyor can be used in myriad locations, including corrosive environments and static-sensitive environments.

The conveyor is strong enough to carry 3,915 pounds per drive. Maximum length per drive is 60 feet. Rotation modules are available so work can be done on multiple sides of a product at one station.

For more information, click www.amcautomation.com, or visit the company’s booth at The ASSEMBLY Show in October.

The Modu-Con 6 has a maximum speed of 200 feet per minute. Photo courtesy Automation & Modular Components

Modular Conveyor Is Quiet

The XR Series conveyor from Quickdraw Conveyor Systems is modular and sectional, with clean, quiet, and static-safe operation. It features bidirectional operation with an open center, slip rollers for accumulation, and precise product movement.

This low-profile conveyor can be integrated with auxiliary devices, such as lift and locate docks, rotators, elevators, metering stops, sensor stops, loaders and unloaders, corner transfers, stackers and diverters.

It has a static load capacity of 60 pounds and a dynamic capacity of 120 pounds. Maximum speed is 90 feet per minute. It’s available in lengths up to 120 inches in 1.5-inch increments.

For more information, click www.qdraw.com, or visit the company’s booth at The ASSEMBLY Show in October.

The XR Series conveyor features bidirectional operation with an open center, slip rollers for accumulation, and precise product movement. Photo courtesy Quickdraw Conveyor Systems

Flat-Top Chain Conveyor

mk North America has introduced two new models to its VersaFlex line of flat-top chain conveyors. Both the A17 and A29 add length and width capabilities, so larger products or those requiring extra support, can make their way through a production line.

Modular and flexible, the VersaFlex conveyor is ideal for complex layouts and features simple and fast configuration and commissioning possibilities. The conveyor features different chain widths and track designs and can transport primary and secondary packaged products, as well as workpieces for assembly lines. The conveyor can adapt to elevation changes, curves and straight sections, all while being driven by a single motor.

The VersaFlex A17 has a chain width of 175 millimeters and a system width of 182 millimeters. It can convey a product width from 70 to 400 millimeters and operate at a max speed of 50 meters per minute.

Two new models have been added to the VersaFlex line of flat-top chain conveyors to accommodate larger and heavier products. Photo courtesy mk North America

The VersaFlex A29 has a chain width of 295 millimeters and a system width of 300 millimeters. It can convey a product width from 70 to 400 mm and operate at a max speed of 50 meters per minute.

For more information, click www.mknorthamerica.com.

To use a welder equipped with dynamic mode, the engineer selects the single-parameter weld mode that provides the best application results. Then, the engineer enters two application-specific “scores,” which act as limits for dynamic mode activity. The first is a material density score that characterizes the hardness or resistance of the material to be welded. A low density score equates to a harder, more resistant material. The second is a weld reactivity score, which fine-tunes the reaction time the welder needs to achieve the desired density setting. In operation, dynamic mode monitors each weld cycle, using the density and reactivity limits to optimize the cycle in response to specific part-to-part variabilities throughout production.

Dynamic mode ultrasonic welding can outperform single-parameter weld modes when:

- assembling electronic components that are sensitive to pressure, vibration or heat damage.

- close-tolerance assemblies containing sensitive components require hermetic seals.

- part structures rely on consistent performance of flexible or elastomeric components.

- elements must be staked or inserted into substrates that vary in hardness or structural consistency.

For example, consider the need to weld a form-fitting, watertight plastic cover onto the shell of a small electronic device. The cover is closely contoured to fit around the electronic components. The cover must be bonded gap-free and watertight, but the weld process and cover structure cannot be allowed to contact or compress the electronics directly beneath. Due to ordinary part variability, reliance on a single-parameter weld mode, such as collapse distance, could exert excessive pressure on the cover and damage the electronics. With the help of material density and reactivity scores, the dynamic welding mode can optimize the collapse distance in each weld cycle to ensure a tight seal without compressing the electronic components.

Dynamic mode is also useful for bonding plastic assemblies that contain compressible materials. Consider, for example, an elastomer-filled, two-way pin connector. The outer shell of the connector consists of a molded plastic cup and lid that contain holes through which metal connecting pins protrude. Inside, the pins are embedded in a compressible core of elastomeric plastic, topped by a weld-on lid that compresses the elastomer radially around the pins. Despite the fact that the elastomeric cores vary in height, sealing of the plastic lid requires a flat fit.

In dynamic weld mode, the density score enables weld-by-weld adjustment that compensates for the varied consistency and height of each plug’s elastomer core. It ensures that the weld actuator travels the required depth and that it “feels” the specified amount of resistance before welding the lid.

Emerson

Slider Bed Conveyor

The DynaPro slider-bed conveyor from Dynamic Conveyor Corp. be used across various industries and applications.

This low-maintenance, low-profile conveyor features tensionless link-style belting to prevent tracking issues and allow for easy belt repair in lieu of replacing the entire belt. The conveyor incorporates many standard features that other conveyor models have as options, including variable speed, reversing, nose bar design for tight transfers, and an M12 connector for machine integration.

The conveyors is driven by compact, high-efficiency 60- and 120-watt DC brushless motors. Relative to other low-profile conveyors equipped with large three-phase AC motors, DynaPro conveyors save an estimated 30 percent on energy costs over a year running in a single-shift operation.

The DynaPro slider-bed conveyor features tensionless link-style belting to prevent tracking issues and allow for easy belt repair. Photo courtesy Dynamic Conveyor Corp.

The conveyor is available in widths of 12, 18, 24 and 30 inches, and lengths of 3, 4, 6, 8 and 10 feet. Maximum speed is 100 feet per minute.

For more information, click www.dynamicconveyor.com.

Edge-Roller Conveyor

The ERT 150 from Dorner Manufacturing Corp. is an edge-roller conveyor for pallet and tray handling provides efficient, noncontact zone control for small and light-load assembly automation applications.

Zone control means little or no back-pressure accumulation. This provides simplified traffic control, eliminating costly pneumatic valves. Slip rollers can be used for the full length of the conveyor with conventional pneumatic pallet stops. Individual rollers can be replaced if damaged without affecting the remaining portion of the conveyor. No belts minimizes contact with product and debris.

The ERT 150 edge-roller conveyor provides efficient, noncontact zone control for small and light-load assembly automation applications. Photo courtesy Dorner Manufacturing Corp.

It features a clean, open-roller design and is suitable for use in ISO Class 4 clean rooms. It is available in widths of 80 to 480 millimeters and lengths of 128 to 2,432 millimeters in 64-millimeter increments. Rollers are 24 millimeters in diameter and spaced 32 millimeters apart, center to center.

It can carry up to 16 kilograms per pallet or tray. Maximum speed is 121 feet per minute.

It has a static-conductive HPDE skirt, and a proximity sensor pick-up on side and bottom. The drive shaft can be moved to any roller zone. A durable linear gearbox design provides a robust and flexible method for driving rollers. Brushless DC motors are reversible. All motor controllers are compatible with Ethernet IP, Modbus TCP or PROFINET.

For more information, click www.dornerconveyors.com.

ASSEMBLY ONLINE

For more information on assembly conveyors, visit www.assemblymag.com to read these articles: