Workstations and Ergonomics

Labor shortages are driving new demand for automation.

Options for Screwfeeding

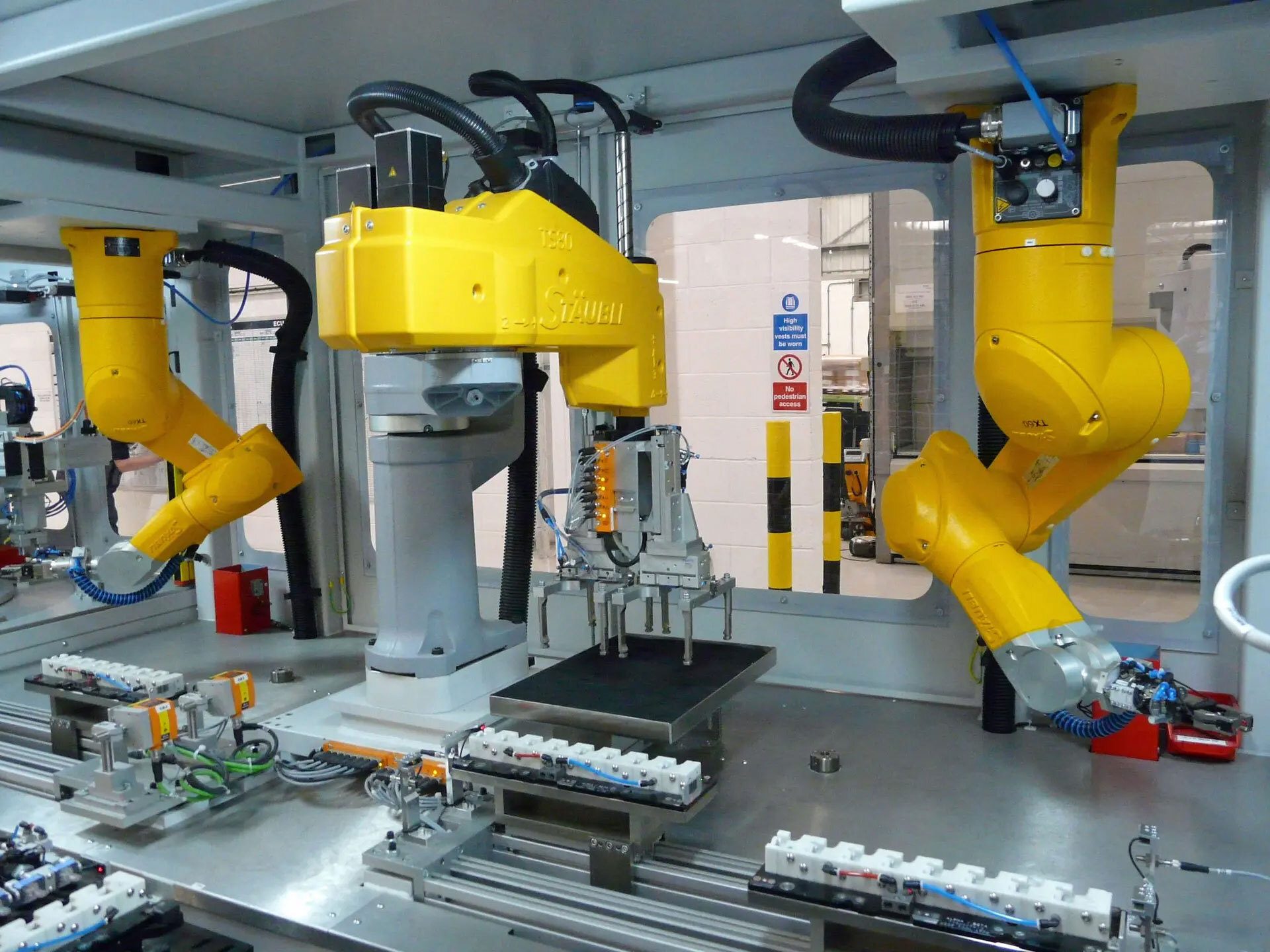

Robots, AGVs and other automation systems can create dangerous workspaces—without the proper safeguards. Photo courtesy DigiKey

Numerous options are available to protect workers from hazardous machinery.

Workers in Automation

How to Safeguard

Eric J. Halvorson // Senior Marketing Manager for Automation and Control Technology // DigiKey // Thief River Falls, MN

As manufacturing becomes increasingly automated, manufacturers must find ways to protect their most important asset: their workforce. Robots, autonomous vehicles, material handling equipment, and more complex systems can create dangerous workspaces—without the proper safeguards installed on the production floor.

Fortunately, there are many forms of safety devices available today. The following devices are just a few examples to get you thinking about the available options.

The light curtain uses photoelectric beams that project from a transmitter to a receiver. If the beam is broken, all work stops immediately until the obstruction is cleared. Photo courtesy DigiKey

Options for Safety Devices

E-stops are one of the most recognizable and most thought-of safety devices on the production floor. Think of them as the immediate interface to stop a machine. The e-stop is typically in a normally closed position within a circuit that, when pressed, opens the circuit and cuts power to the device. To re-engage the circuit, the e-stop must be pulled out or in a twist to the open configuration, returning the circuit to operational.

According to OSHA, ANSI, NFPA79, ISO 13850 and IEC 60204-1, e-stops are required to be installed where they are easily accessible to the operator. Resetting the e-stop should not allow operations to resume. A second redundant action is required, such as an all-clear function through a circuit on the programmable logic controller (PLC).

Door interlocks are another physical safety device commonly integrated on the production floor. Safety interlocks are used on physical barriers, such as gates and doors. The safety interlock, much like the e-stop, operates in a normally closed circuit. When the gate or door is opened, the circuit is interrupted, and all work is halted. Interlocks are required to meet ISO 14119 and ISO 13849.

Laser safety scanners have become very popular with the rise of cobots. Photo courtesy DigiKey

The e-stop is typically in a normally closed position within a circuit that, when pressed, opens the circuit and cuts power to the device. Photo courtesy DigiKey

Operator presence triggers are another option. They come in many shapes and sizes. For example, a safety mat is activated by the presence of someone standing on the mat. It may trigger a machine to stop, go in reverse, or deactivate when presence is detected. This helps to ensure that workers are out of the way, allowing the machine to operate.

Laser safety scanners have become very popular with the rise of cobots. The scanner uses a 360-degree beam to determine how close a worker or an object is in relation to the robot. The scanner will tell the robot to decrease its speed depending on the closeness of the individual or object. The scanner is usually programmed with preset zones. In the orange or yellow zone, the robot is slowed to collaborative speed until the object or person has exited. If the red zone is triggered, the robot will then slow even further or even stop completely until safe.

Light curtains are especially effective in areas where crushing or pinching hazards exist, such as hydraulic presses. The light curtain uses photoelectric beams that project from a transmitter to a receiver. If the beam is broken, all work stops immediately until the obstruction is cleared. Light curtains are particularly effective when solid gates or barricades are impractical. They come in a variety of sizes and levels of sensitivity to fit the needs of the manufacturer in meeting OSHA standards.

Safety PLCs are control systems designed to monitor and manage safety-critical functions and serve as a way to program-in safeguards to monitor the health of a line. Through redundancies, the safety PLC is designed to run diagnostics to determine if a part of the line or a component is faulty. If an event, such as a broken wire or motor, is running outside of spec, the safety PLC will immediately shut down the entire affected system to prevent injury or damage. The safety PLC must adhere to a specific safety integrity level and must meet IEC 62061, ISO 13849-1 and IEC 61058.

These are just some of the many safety devices available to manufacturers and systems integrators today. When automating a process, engineers are well-advised to seek advice from a safety expert to ensure they have covered all the possible hazards within their facilities. These experts can help you to navigate OSHA, ANSI and all other safety regulatory agencies.

For more information on safety technology, click www.digikey.com.

Inspection System

ASSEMBLY ONLINE

For more information on safety technology, visit www.assemblymag.com to read these articles: