Manufacturing Software

Labor shortages are driving new demand for automation.

Options for Screwfeeding

With the help of simulation software, engineers can modify a body-in-white assembly line early in the design process, when changes are easy and less costly to make. Photo courtesy Stellantis

Simulation software enables Stellantis engineers to save time and money when commissioning a robotic welding line.

Body-in-White Assembly

Stellantis Increases Efficiency of

Nicolas Imholz // Welding Process Engineer // Stéphane Prat // Underbody Geometry Specialist // Stellantis // Sochaux, France

At Stellantis, we don’t need to talk about quality, because it’s a given. That said, we continually strive to enhance our processes and achieve new targets in terms of costs, time to market, and carbon neutrality.

Geometry engineering is deeply intertwined with these goals through various drivers, including the reuse of existing parts, a strong “first-time right” mentality, and an ongoing quest for process downsizing.

Drivers available for the geometry engineering department to meet Stellantis’ targets. Photo courtesy AutoForm Engineering GmbH

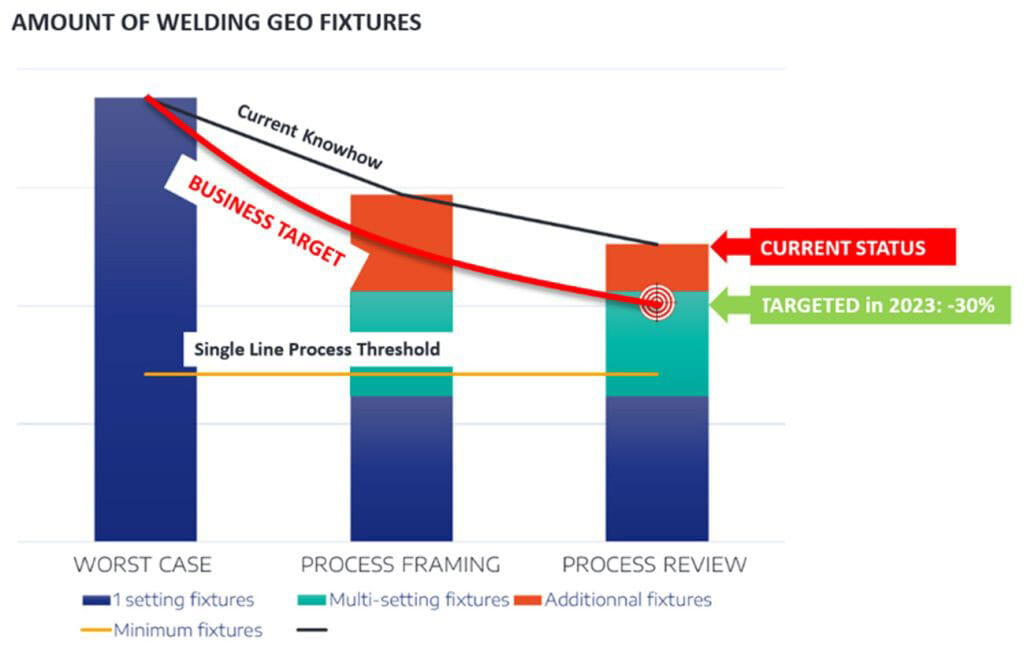

As an example, the geometric design of the welding process significantly influences cost efficiency. Consider the overall costs of the fixtures needed for assembly. In the theoretical worst case, each assembly would require its own set of fixtures. However, our expertise allows us to reduce costs by designing some fixtures that can accommodate more than one vehicle model and additional fixtures where necessary.

During the process review phase for a recent model change, we determined that we could further reduce costs through optimization activities, thus decreasing the number of additional fixtures required on the body-in-white (BIW) line. Our target was to reduce the number of unique fixtures by 30 percent by the end of 2023.

This graph compares the overall costs of geometric fixtures for assembly: worst case (only unique fixtures), process framing phase (some multi-use fixtures and some unique fixtures), and process review phase (minimal number of unique fixtures). Our goal was to reduce the number of unique fixtures by 30 percent. Source: AutoForm Engineering GmbH

Results Through Simulation

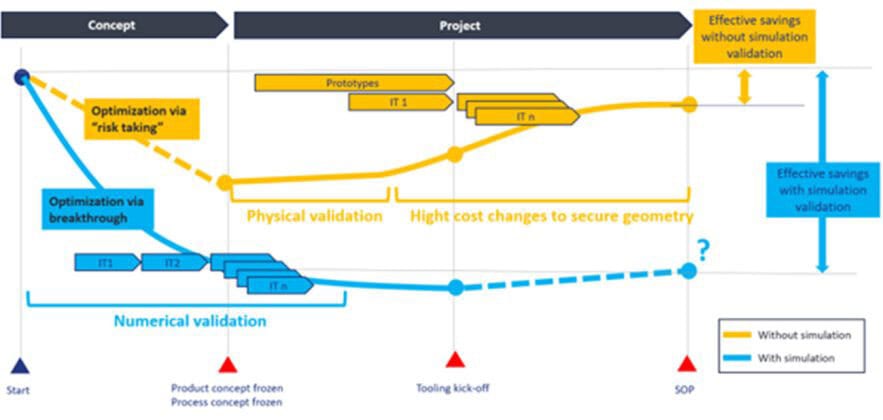

Simulation proves invaluable in reaching our business objectives. Without simulation, we face limitations in the number of possible validation loops for our assembly processes, and each loop typically consumes a substantial amount of time as it relies on physical validation. By that point, it’s often too late for significant product changes, and any geometry optimization necessitates costly mechanical corrective actions that also adversely affect time to market.

Assembly simulation allows us to evaluate concepts early, reduce validation loop durations, and increase their frequency, significantly influencing the product and process during a phase when optimization possibilities abound and ultimately reducing production risks.

Without simulation, process optimization becomes less ambitious since the opportunities to mitigate risks during physical validation are limited. Actual gains remain marginal because the few optimization loops secured during validation come at high costs to minimize time to market.

This graph shows the benefits of using simulation for assembly processes assessment. The yellow line shows the process without simulation. Corrective actions occur during tryout when change costs are high. The blue line shows the process with simulation. Corrective actions can be evaluated during engineering, when change costs are lowest, resulting in greater savings overall. Source: AutoForm Engineering GmbH

For us, simulation software from AutoForm Engineering GmbH has been invaluable. The company recently released a new version of its AutoForm Assembly R12 software. This version offers new capabilities and enhancements for the BIW assembly process chain, in particular for hemming, process engineering, and process optimization and evaluation.

AutoForm Assembly R12 offers advancements and new options for assembly process engineering. During this stage, engineers have to import assembly CAD data, which often includes a large amount of information that is not needed in its entirety for defining the assembly process. AutoForm Assembly R12 allows engineers to filter CAD data specifically for defining the assembly process. They can then easily select elements to import which, once imported, maintain the same CAD structure and original element names.

In addition, AutoForm Assembly R12 significantly improves the behavior of the thermal model, which was developed to enable the prediction of thermally induced distortions that occur during welding processes. Line welds now consider the time-dependent thermal behavior of the process, enabling more realistic welding simulations. This allows engineers to optimize welding processes already in the process engineering stage.

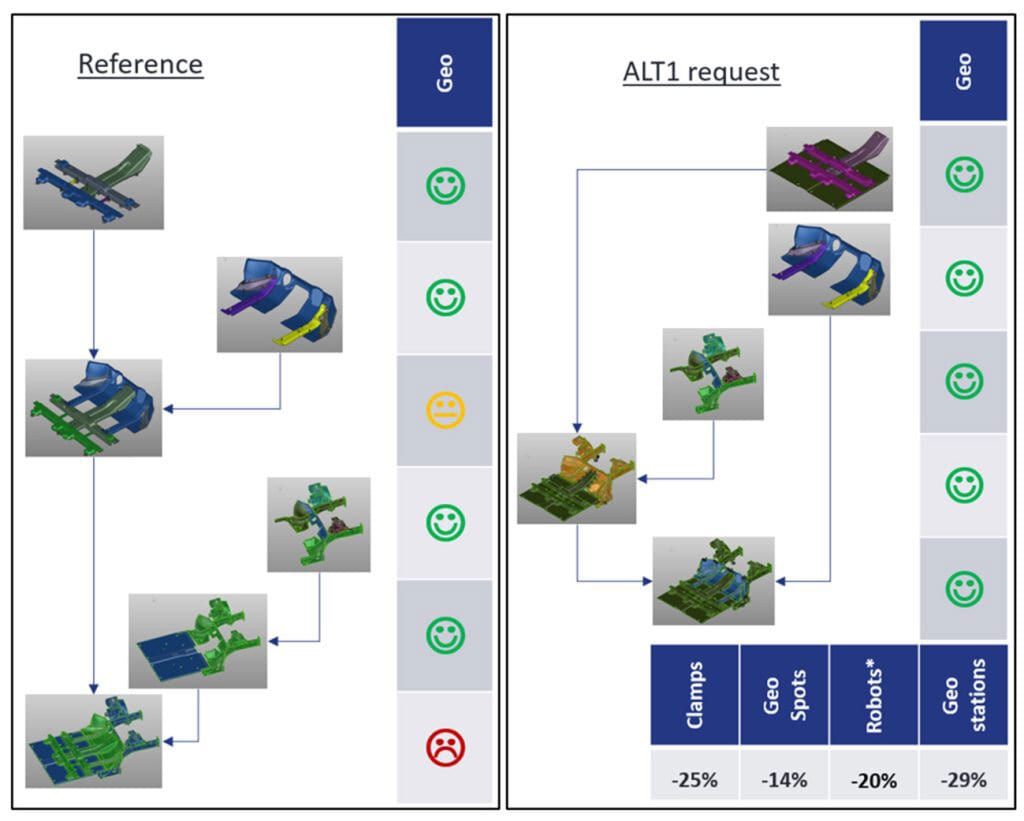

Assembly simulation enabled us to optimize one of our welding processes. Source: AutoForm Engineering GmbH

The software also offers new capabilities that are important for assembly process optimization and evaluation. In practice, assembly equipment is continually adjusted to resolve dimensional deviations and their effects on production. With AutoForm Assembly R12, process adjustments can be made virtually, enabling engineers to define which clamps should be considered for shimming and which joins should be considered for teaching. Selected clamp positions can be moved within the defined range, and nearby joins can be taught as needed based on sheet movement. By running multiple simulations, the software enables users to determine the optimal parameters that can be applied to resolve accuracy issues in assembly. When a solution is found, the settings can be easily mirrored in the physical process, eliminating the costly traditional trial-and-error approach.

AutoForm Assembly R12 brings new options for the hemming operation. Parts that have several disconnected flanges can now be hemmed with a single tool. The software enables a more realistic process definition, a reduction in the number of hemming tools, and a shorter amount of time for the simulation setup.

“The software allows for an even more reliable digital process representation, which serves as a blueprint for the physical process in BIW assembly production,” says Markus Thomma, Ph.D., chief marketing officer of the AutoForm Group. “The digital process model enables users to determine which adjustments need to be made to the physical process. With AutoForm Assembly R12, users can significantly reduce the number of physical tryout and quality loops, which results in lead time and cost savings.”

Inspection System

Simulation at Stellantis

Thanks to AutoForm’s assembly simulation software, we discovered innovative and daring solutions for one of our assemblies that would never have materialized without simulation.

We managed to reduce the assembly sequence from six steps to five. This yielded several benefits, such as a 14 percent reduction in the number of “geospots” (welding points for geometric conformity) and a 20 percent decrease in the number of robots, all while enhancing the overall assembled geometry. Such a drastic process optimization would have been unfeasible after concept freeze without introducing time-to-market delays and significant cost overruns.

The use of assembly simulation is a game-changer for process optimization. We found that product conception and assembly sequence definition often led to an excess of clamps and geospots, occasionally surpassing what robots could handle, resulting in inadequate cost efficiency during the design and test phases. Additionally, we found significant transfer issues between our assembly posts, which could be resolved by strengthening subassemblies.

Through our study, we improved geometry cost efficiency by reducing the number of geospots and enhancing subassembly stiffness, all accomplished via sequence and product changes conducted within the simulation.

ASSEMBLY ONLINE

For more information on simulation software and body-in-white assembly, visit www.assemblymag.com to read these articles: