AUTOMOTIVE ASSEMBLY

CONTACT

Austin

Lightweight battery-powered aircraft are ready for take-off.

ICE Innovation Resurrects an Old Technology

Austin Weber // Senior Editor // webera@bnpmedia.com

Next-generation systems are making diesel- and gas-powered engines cleaner and more fuel efficient.

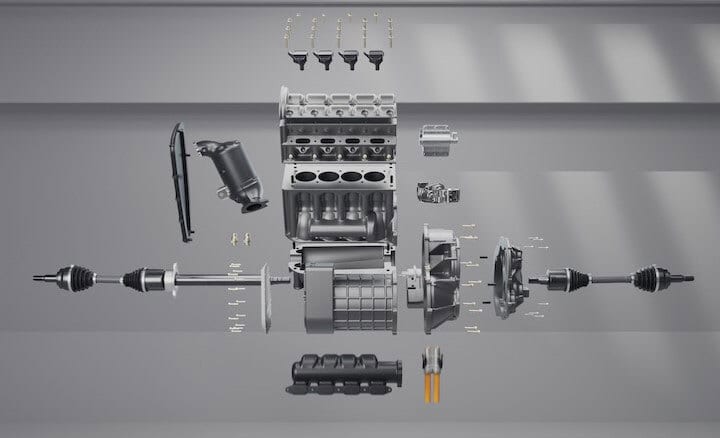

Internal combustion engines will continue to be in demand for decades. Photo courtesy General Motors

American author Mark Twain once remarked: “Reports of my death are greatly exaggerated.” The same can be said about the good-old internal combustion engine (ICE). New technology is making traditional gas and diesel power trains cleaner and more fuel-efficient.

While automakers and suppliers around the world have invested billions of dollars developing electric vehicles, most experts predict that ICE systems will continue to exist for at least the next three decades. That’s because the proven form of propulsion has been refined and improved.

Mechanically, ICE power trains work the same as they always have. They rely on an intricate mix of crankshafts, cylinders, flywheels, manifolds, pistons, pumps, rocker arms, valves and other under-the-hood components.

Next-Generation Technology

Next-generation technology, such as cylinder deactivation, direct injection, exhaust gas after treatment, friction reduction, hybridization, turbocharging and variable valve timing, is making combustion engines smarter and better than ever.

“Traditional internal combustion engines still have huge relevance,” says Richard Osborne, global technical expert for sustainable engines at Ricardo Group. “There are 1.5 billion passenger vehicles on the road, and of these only around 40 million are EVs (including plug-in hybrids), which is around 2 percent of the total number.

AUTOMOTIVE ASSEMBLY PRODUCTS

Features

• Open frame designs allows access all around

• Tensioned with chordal compensating cam to reduce vibration

• Link pins use needle roller bearings for increased longevity

• Multiple drive options

Performance

• Zero-backlash in all directions

• High load capacity

• Long-term accuracy

• Fast and flexible indexing

Sankyo Automation

937-498-4901

beilert@sankyoautomation.com

www.sankyoautomation.com

IC80 Inline Chassis

“And, while there are EV mandates in some countries and jurisdictions to reduce or eliminate the sale of new ICE passenger vehicles, these aren’t global and there is unlikely to be a full scale switch any time soon,” explains Osborne. “One reason for this is that there isn’t yet the necessary infrastructure in place to accommodate the transition to 100 percent EVs.

“In the world of heavy-duty and off-highway vehicles, which includes locomotives, ships, tractors and trucks, diesel power will continue to dominate for decades. This is due to infrastructure, in addition to the cost, size and weight of batteries. But, there is also growing interest in alternative fuels, such as ammonia, hydrogen and methanol."

“Certain use patterns—particularly those involving towing or hauling heavy loads over long distances—present unique challenges for EVs,” says James Martin, manager of automotive consulting at S&P Global Mobility. “Even though electric motors can, in many instances, tow more than comparable ICE vehicles, the added workload can deplete range at a much faster rate compared to unloaded operation.

“It is not unusual for range to be reduced to half of the stated range,” warns Martin. “For long-distance towing and hauling, diesel and gasoline are still more efficient, and refueling less complex.

Makita’s cordless tools are the perfect solution for the high demands required of today’s automotive assembly factory. To meet these challenges, Makita offers precision torque you can trust, documented energy savings, proven ergonomic/safety benefits, and wireless communication that can document good and bad fastenings. To see how Makita’s complete lineup can benefit your factory, contact us today!

Makita USA, Inc.

Contact Sue Stenhaug

800-867-8265 ext 3121

sstenhaug@makitausa.com

www.makitaassemblytools.com

The Leader in Cordless Precision Fastening!

“Undoubtedly, EVs are most cost efficient for consumers who have the capability to utilize home- and work-based AC charging on a regular basis,” Martin points out. “Charging at home will prove to be difficult and, in some cases impossible, especially for residents of multifamily dwellings who don’t have access to dedicated parking. A reliance on externally sourced charging, such as DC fast charging, can be as pricey as filling a tank of gasoline, eliminating the primary economic benefit of EV ownership.”

“ICE vehicles are expected not only to have staying power in the marketplace, but growth for another decade or more,” predicts Allen Schaeffer, executive director of the Engine Technology Forum, an organization that promotes a greater understanding of the benefits of internal combustion engines, fuels and technologies. “Various market forecasts predict combined annual growth rates for ICE of as much as 9 percent [between now and the end of this decade].

“Though increasingly stringent future standards are designed to accelerate the introduction of zero-emission vehicles, it is still projected that ICE technology will power one-third to one-half of the new vehicle fleet in 2032,” says Schaeffer. “The staying power of advanced ICE is even more pronounced in heavy-duty off-road applications in agriculture, construction, marine, rail and power generation.”

According to Schaeffer, ICE technology will continue to thrive and dominate most sectors of the economy for decades to come for three reasons:

• Near sole reliance on ICE and its supporting infrastructure across wide sectors of the global economy for which there is no suitable alternative.

• Continuous improvements in efficiency and lower emissions, as well as significant opportunities for using lower carbon fuels that position it to compete with emerging alternatives.

Get the power of POP® Rivets paired with process monitoring expertise:

- Eliminate Missing Fasteners

- Stop Leaks & Product Damage Caused by Incomplete Joint Stackup

- Meet Data Collection Goals

- Prevent Process Circumvention

- Fully Connected Process Monitoring or Stand-Alone Solution

Request your BRF30PB-20 demo today.

STANLEY Assembly Technologies

(440) 461-5500 Option 2

Complete Process Monitoring Made Easy

• Delays and uncertainties due to funding support, infrastructure and market acceptance, as well as many other factors inherent in introducing new fuels and energy systems.

“The path to the future for ICEs is well underway,” claims Schaeffer. “It involves building on past progress to meet new emissions and fuel efficiency requirements, and a considerable increase in the use of low-carbon fuels like renewable gasoline, renewable diesel, renewable natural gas, biodiesel and hydrogen, as well as e-fuels now under development.”

Widespread Interest

Automakers have gone through a cycle of downsizing and boosting gasoline engines. “As the transition to more electrified vehicles slows, we are seeing renewed efforts to downsize and boost engine products that were not addressed in the first wave of downsizing and boosting,” says Martin.

“We are also seeing more variable valve train control technologies being added and improved,” explains Martin. “Another area that is receiving attention is the more efficient management of fuel input into the combustion cycle.

“Automakers are implementing higher pressure direct injection and higher compression ratios to foster the cleaner and more complete burning of the fuel mixture,” adds Martin. “This can improve both fuel economy and emissions.”

In recent years, German automakers have led the charge to electrification, pouring billions of dollars into developing batteries, drivetrains, power electronics, traction motors and other components. But, several recent developments indicate that they aren’t ready to throw in the towel on ICE power trains anytime soon. Indeed, there has been a renewed focus on improving combustion engine efficiency.

The Omega 750 S excels in high-precision automated wire harness assembly, handling a wide processing cross-section range from 0.13 to 1.5 mm² (26-15 AWG). It processes wires sequentially for faster cycle times and higher output, with advanced automation, software integration, and an intuitive interface ensuring top productivity and quality.

Komax

847-537-6640

Fully Automatic Wire Harness Production

For instance, Mercedes-Benz AG recently announced that it plans to release 19 new gas-powered models by the end of 2027. At that time, it predicts that 70 percent of its vehicles will continue to be ICE powered. The automaker also intends to bring back V8 power with an all-new mild-hybrid gasoline engine for its CLE coupe and cabriolet models.

BMW AG plans to launch a new generation of ICE vehicles, starting with the G65 X6 next year. The company recently filed a patent for a new pre-chamber ignition system that significantly improves the efficiency of gasoline engines. Another patent application involves a system where an ignition cylinder responsible for the primary combustion is linked to an expansion cylinder via a two-way valve system.

The latter receives some of the exhaust gases, using the crankshaft for precise timing to optimize energy transfer. The ignition cylinder absorbs most of the explosive force needed to drive combustion, while the expansion cylinder minimizes wear and tear on components.

Engineers at Porsche AG are rethinking the design of pistons to improve thermal efficiency and reduce weight. The sports car company recently filed a patent for a two-piece piston design that features integrated oil channels. A 3D-printed piston crown is attached with expansion screws to a lower piston hub. This two-part construction creates enclosed internal oil channels designed to enhance cooling.

- PW Series – Cordless Shut-Off Hydraulic Pulse

- TDIS Series – Pneumatic Shut-Off Hydraulic Pulse

- SCEP Series – Cordless Shut-Off Clutch

- IWT Series – Cordless Shut-Off Impact

- TDCS-D Series – Pneumatic Shut-Off Clutch

TORQTEC

919-561-5536

info@torqtec.net

www.torqtec.net

Featuring our DuPas Brand offering an operating range of 1 to 450 NM in the following Models:

Next-generation technology is making combustion engines smarter and more efficient. Photo courtesy Toyota Motor Corp.

At last month’s Bauma trade show in Munich, Germany, several exhibitors unveiled next-generation diesel engines for off-highway applications.

Cummins Inc. showcased the X15, the latest addition to its HELM fuel-agnostic engine platform designed to power large construction equipment such as cranes, excavators and wheel loaders. It delivers up to 10 percent better fuel economy vs. previous models, with comparable ratings and duty cycles. The engine is compatible with a variety of current, and future, low- and zero-carbon fuels, including natural gas, clean diesel and hydrogen.

Liebherr Group unveiled a combustion engine powered by ammonia, which is becoming an increasingly popular fuel in the maritime and mining industries. Ammonia has 10 times the energy density of lithium-ion batteries and, unlike hydrogen, does not need to be stored in high-pressure tanks.

Suppliers are also playing an active role in improving combustion engines. One company leading the way is Tenneco Inc., a Tier One firm that specializes in power train and ride performance products. Its brands include Federal-Mogul, Fel-Pro, Monroe and Walker.

“Electrification will not come as fast as we earlier thought,” says Christian Herbst-Dederichs, vice president of power train product and technology at Tenneco. “Therefore, we need to think about alternative strategies.

“The combustion engine has a lot of advantages,” claims Herbst-Dederichs. “There’s also a cost-performance tradeoff that has to be taken into consideration. For instance, the cost of battery-powered vehicles is still higher than gas-powered cars.”

Tenneco engineers have been working on creative ways to take traditional internal combustion engines to the next level, making them cleaner, more efficient and sustainable.

“One way is to increase the thermal efficiency of the combustion,” notes Herbst-Dederichs. “Another way is electrification of auxiliary devices, such as oil and water pumps. Last, but not least, is hybridization.”

According to Herbst-Dederichs, many efforts to improve internal combustion have focused on improving part-load efficiency. “Engine part-load optimization (operating engines at low load cycles) can reduce emissions and cut fuel costs,” he points out. “For instance, we can use valve timing technology to change the compression ratio.

“Friction reduction is also an important way to improve ICE power trains,” says Herbst-Dederichs. “Reducing the viscosity of oil enables it to move easier inside engines. However, with thin oil, mechanical wear reduction is a challenge that needs to be addressed.”

Tenneco’s DuroGlide coated piston rings are designed to reduce friction and increase wear resistance on sliding surfaces, which results in improvements in fuel efficiency and CO2 reduction.

Herbst-Dederichs also says alternative fuels, such as hydrogen, can improve the operating efficiency of combustion engines. That’s why Tenneco has doubled down on efforts to develop hydrogen internal combustion engine (H2-ICE) critical components for the commercial vehicle sector. In fact, it recently opened a hydrogen materials test laboratory in Nuremberg, Germany, in addition to new state-of-the-art test cells at facilities in Burscheid, Germany, and Ann Arbor, MI.

“These additions enhance [our] research and development capabilities aimed at accommodating the soaring demand for hydrogen propulsion for agriculture, construction and heavy-duty trucking,” says Herbst-Dederichs. “By investing in cutting-edge infrastructure and research, we aim to accelerate the adoption of hydrogen power and contribute to global efforts to reduce carbon emissions.”

Combustion engines are a proven form of propulsion that have been refined and improved. Photo courtesy Nissan Motor Co.

A New ICE Age?

There are a number of ways that automotive engineers can make ICE power trains cleaner and more efficient. In particular, S&P Global Mobility’s Martin cites several promising innovations, including:

• Pairing with varying levels of electrification. “This can be done in a way that focuses the primary operating range of the ICE in its ‘sweet spot’ for fuel efficiency and power delivery,” says Martin.

• Optimizing the transmission pairing. “Implementation of multispeed and dual-clutch automated transmissions can help maintain ICE operation at lower operating rpm,” explains Martin. “This can help improve fuel economy and reduce emissions.”

• Development of alternative operating cycles. “There have been developments made in the improvement of existing operating cycles, as well as development of new operating cycles,” notes Martin. “Improvements in operating cycles have tended to focus on variable geometry and timing. Variable valve lift, variable valve timing, cylinder deactivation and even variable compression ratio have been implemented, and some can see additional widespread usage. There are also opportunities in advances in exhaust gas recirculation (EGR) that capture, clean and reuse exhaust gases to better enrich the combustion mixture, allowing for cleaner and more efficient burning of fuel.”

• Capture Technologies. “Diesel particulate filters have been in use for quite some time,” says Martin. “Similarly, gas particulate filters are seeing growth as regional regulations focus more on hydrocarbon and nitrous oxide particulate emissions.”

According to some experts, thermal efficiency is key to making ICE power trains cleaner and more efficient. That’s because gas-powered vehicles waste up to 80 percent of the energy in their fuel. Most of the energy ends up as heat, and only a small fraction actually reaches the wheels because of the multistep process that ignites pistons and turns crankshafts. Diesel engines traditionally have better efficiency, but much less than EVs.

There has been a renewed focus on improving combustion engine efficiency. Photo courtesy BMW AG

Thermal efficiency can be broken down into four areas:

• Thermodynamic efficiency, which relates to all of the heat losses from engines. This can be improved using exhaust gas recirculation or lean-burn operation.

• Gas exchange efficiency relates to pumping losses. This can be improved through the adoption of variable valve trains.

• Mechanical efficiency relates to friction losses, which can be reduced using low-friction coatings.

• Combustion efficiency relates to whether all the fuel takes part in combustion.

“Sustainable fuels, such as biofuels, e-fuels, hydrogen and methanol, will play a big role in helping to reduce CO2 emissions,” predicts Ricardo’s Osborne. “One option for this will include ‘drop-in’ fuels that could be used to supplement traditional diesel or gasoline, either partially or completely.

“This could help to overcome some of the infrastructure challenges relating to universal adoption of electric vehicles,” says Osborne. “And, it will be helpful for off-highway vehicles and maritime applications, and countries where there is a lot of distance between recharging infrastructure.

“The auto industry will also be able to find improvements by looking at the entire vehicle life cycle, such as considering emissions generated during resource extraction or energy used as part of manufacturing,” Osborne points out.

In addition, other technologies are being deployed, such as hybridization, which combines the advantages of ICE and EV technology.

“A key benefit of hybridization is that it enables engines to run over a narrower operating window, allowing them to be optimized specifically for those conditions,” explains Osborne. “An example of this is Ricardo’s Magma xEV research project where we used hybridization to improve brake thermal efficiency by 45 percent.

“We are also finding that single-cylinder research engines still play a vital role in engine development, as they enable OEMs and suppliers to test, refine and enhance performance and efficiency, while reducing emissions in both gas and diesel engines,” says Osborne.

“In addition, artificial intelligence and machine learning technology are being used in engine development,” notes Osborne. “This allows manufacturers to simulate an engine over a lot of different operating cycles and conditions, and identify efficiency improvements without the need to run the vehicle.”

Automakers have gone through a cycle of downsizing and boosting gasoline engines. Photo courtesy Honda Motor Co.

“Combined with a growing momentum toward in-vehicle digitalization and smart monitoring leveraging cutting-edge sensors, real-time diagnostics and AI-driven engine control systems, gas and diesel vehicles continue delivering optimal performance, enhanced efficiency, and extended engine life and performance,” adds Amit Chadha, CEO and managing director of L&T Technology Services Ltd.

“The trend toward more efficient and greener ICE vehicles involves the adoption of innovative combustion techniques like homogeneous charge compression ignition and low-temperature combustion to improve efficiency, while reducing harmful emissions,” says Chadha. “There is also an accelerated shift toward the use of lightweight materials, advanced engineering across high-strength alloys and composites, and precision manufacturing of engine components to minimize weight and energy losses.”

New Engine Reveals Future Power Train Concept

At last month’s Auto Shanghai trade show, Horse Powertrain Ltd. unveiled a compact, modular hybrid engine that provides a glimpse of how some light passenger vehicles could be powered in the near future. The start-up company is a joint-venture between China’s Geely Automobile Holdings and France’s Renault Group.

The Future Hybrid Concept integrates an internal combustion engine (ICE), electric motor and transmission into a single, compact unit. It enables automakers to meet changing customer demand, while eliminating the need for multiple platforms and production lines.

This modular power train integrates an internal combustion engine, electric motor and transmission into a single, compact unit. Illustration courtesy Horse Powertrain Ltd.

The lightweight power train fits within existing battery electric vehicle (BEV) platforms, and serves as a range extender to the existing battery, with its transmission and driveshafts enabling all-wheel-drive operation both in EV and parallel modes. It can be powered by a range of fuel types, including gasoline, ethanol, flex fuels and pure methanol.

The Future Hybrid Concept consolidates the complex hybrid power train component stack into one compact unit, achieving significant system integration efficiencies. By eliminating most of the tooling and unique manufacturing steps required for pure hybrid engine assembly and installation, the architecture also saves significant resources for OEMs that want to produced mixed propulsion vehicles on the same line.

“For over a decade, it looked like BEVs were the only path to net zero, and OEMs planned accordingly,” says Matias Giannini, CEO of Horse Powertrain. “However, we’re now shifting toward a technology-neutral world, with different markets and applications each pursuing their own sustainable mobility journey.

“Our Future Hybrid Concept helps [automakers] solve this problem,” claims Giannini. “This compact, integrated power train concept allows OEMs to offer power train diversity with minimal disruption to production processes and resource expenditures.”

“The Future Hybrid Concept is designed as a single-piece combustion engine, motor and transmission unit, reducing the complexity of a hybrid power train,” adds Ragnar Burenius, chief engineer of xHEV systems at Horse Powertrain. “This allows more flexibility for its packaging, enabling it to be integrated into existing BEV platforms with minimal vehicle modifications.

“The compact size and geometry of the [system] has been designed to replace the front electric drive unit of a BEV,” explains Burenius. “Requiring only minor modifications, the power train bolts directly to a vehicle’s subframe, allowing OEMs to offer hybrid models on BEV platforms without having to commit to significant redesigns. It can also fit a traditional combustion vehicle platform."

Future Challenges

By harnessing AI, automotive engineers hope to make further improvements to ICE power trains. “However, there are limits on what physics is able to do with combustion engine efficiency,” warns Tom Howell, conventional power train segment leader at AVL List GmbH, a company that specializes in developing and testing sustainable power systems for road, rail and marine vehicles. “It will be hard to get beyond 53 percent thermal efficiency with diesel engines, which has already been achieved by engineers in China.”

“There are still improvements that can be made to make combustion engines cleaner and more efficient,” argues Ricardo’s Osborne. “For passenger vehicles, there remains a focus on tailpipe emissions. Regulations such as the Euro emissions standards have led to real improvements in air quality. When the Euro 7 regulations are implemented [in late 2027], ICE vehicles will approach zero-impact levels of pollutant emissions.

“Life-cycle assessment (LCA) is also a vital tool that can be used to compare the environmental impact of different power train types,” explains Osborne. “When we’ve worked with manufacturers and suppliers in the automotive industry on LCAs, we’ve been able to identify hot-spot areas of environmental impact in the life cycle which can be prioritized for improvements. This includes things such as energy usage, material sourcing and waste reduction.”

“Non-exhaust emissions are an area where there is room for improvement, regardless of vehicle type, such as tire and brake emissions that can be damaging to health,” says Osborne. “With the introduction of Euro 7, we will see the first standards in this area. But, there is more work that manufacturers can do to reduce these types of emissions, which will help reduce environmental impact and improve human health.

“The final issue we need to tackle is how we can produce enough sustainable fuels for all industries, including vehicle use,” notes Osborne. “This is where having a diverse range of fuel types can play a role.”

“One of the biggest challenges going forward will be the ability to manage the cost to implement multiple technologies as the scale of production of most ICE products is gradually reduced,” adds Martin. “In most cases, these technologies are not customer selectable and therefore not considered customer pay options.

“There are also challenges involved in the integration of multiple technologies, in many cases in parallel with some degree of electrification,” warns Martin. “The controls engineering required to execute these broad-based solutions continues to grow in complexity.”

“A company with Ford’s scale can really influence the supply chain and business practices across our entire industry,” adds Sue Slaughter, purchasing director at Ford Motor Co. “It is so important that we not only think about how [we] can use our purchasing power to fuel our business needs, but also to advance sustainability.”

Because the automotive supply chain is extremely complex, the Guiding Principles contain expectations about business ethics, working conditions, human rights, health and safety, environmental leadership and supply chain due diligence for suppliers at all tiers. All suppliers are expected to uphold these standards and enforce them throughout their supply chain.

The Guiding Principles are based on fundamental elements of social, environmental and governance responsibility that are consistent with applicable laws and international standards created by organizations such as the United Nations.

Topics covered under the revised guidelines include the following:

Business ethics, including counterfeit parts and data protection.

Environmental issues, such as air quality, carbon neutrality, chemical management, circularity and water management.

Health and safety issues, such as personal protective equipment and workspace.

Human rights and working conditions, such as benefits, wages and working hours.

Responsible supply chain management, such as ethical sourcing of raw materials.

The BMW Group has implemented several projects in its packaging logistics unit to help the environment and conserve resources. The goal of the initiative is to work closely with suppliers to reduce carbon emissions and adhere to the principles of a circular economy.

BMW’s European assembly plants are using more recycled material in their packaging. For newly awarded contracts, the proportion of recycled material in reusable packaging for logistics purposes will almost double this year from around 20 percent to over 35 percent.

Using alternative sustainable materials, reducing single-use packaging, introducing lightweight packaging in certain areas and reducing transport volumes will also help cut carbon emissions.

BMW is monitoring the impact of individual measures via a CO2 calculator for packaging. The automaker’s overall aim is to reduce CO2 emissions in the supply chain by 20 percent per vehicle compared to 2019.

“Our re:think, re:duce, re:use, re:cycle approach is being implemented consistently in packaging logistics,” says Michael Nikolaides, head of production network and logistics at BMW Group. “We’re using innovative strategies to consistently reduce the volume of resources we use, thus reducing our carbon footprint.

“We are also doing our part to get the BMW iFACTORY up and running, with a particular focus on the ‘green’ side of things…with an emphasis on flexibility and efficiency, sustainability and digitalization,” explains Nikolaides. “It provides an answer to the challenges involved in the transformation to e-mobility and [leverages] the latest technologies to create a production process that uses minimal resources.”

According to Nikolaides, BMW is using more recycled material, such as expanded polypropylene (EPP) packaging. “Our newly developed EPP packaging already contains 25 percent recycled material,” he points out. “EPP is used in special containers, as its shape can be adapted to the components being packaged, allowing them to be transported safely.

“Around 360,000 of these containers are needed each year,” claims Nikolaides. “Using 25 percent recycled material allows us to save almost 280 tons of CO2 annually. There are plans to increase this proportion of recycled material even further, with the first pilot schemes with 100 percent recycled material currently underway. If these tests are successful, this configuration will become standard for new contracts from 2024.

“An additional 680 tons of carbon emissions savings can be made every year by using covers and so-called small load carriers with 50 percent recycled contents,” says Nikolaides. “As things stand, these measures are focused within the European markets due to the current waste management situation and available recycling infrastructure. But, we are working toward expanding to our locations in China, Mexico and the United States.”

BMW also plans to use folding large load carriers in place of traditional pallet cages made of steel. The plastic alternatives will be made from over 90 percent recycled material. They work in a similar way to the collapsible shopping crates that most people are familiar with.

When they’re empty, the carriers can be folded up, making them easier to transport. Nikolaides claims that using 15,000 of these new containers will reduce CO2 by around 3,000 tons per year.

“When it comes to packaging, the sky’s the limit,” says Nikolaides. “We’re launching pilot projects using bio-based materials to replace oil-based substances such as polyethylene and polypropylene.

“We are also investigating whether and in what ways we can use materials from recycled household appliances in our packaging,” explains Nikolaides. “In the long term, our aim is to use alternatives to raw materials across the board.”

BMW Initiative Targets Sustainable Packaging

BMW is using sustainable packaging in its assembly plants. Photo courtesy BMW Group

ASSEMBLY ONLINE

For more information on internal combustion engine manufacturing, visit www.assemblymag.com to read these articles: