CONTACT

Austin

Lightweight battery-powered aircraft are ready for take-off.

Motion control technology is constantly evolving.

Consider collaborative robots, for example. Cobots are designed to operate safely with or near people. But, that inherent safety goes out the window if the cobots are paired with actuators or end-effectors that are not designed to be collaborative. That’s why Thomson’s new Movotrak cobot transfer unit caught our eye.

Read all about that and three other innovative new motion control products below.

Linear Axis Extends Range of Cobots

The Movotrak cobot transfer unit is a linear actuator that serves as a 7th axis of motion for collaborative robots. With a horizontal range of up to 10 meters, the axis is equipped with collision detection technology that stops the cobot when it encounters an obstacle.

“With the extension of the cobot’s collaborative functionality along the 7th axis, manufacturers can deploy cobots to work more closely and flexibly with humans. Using the same cobot for more than one workstation boosts productivity and extracts maximum value from the initial cobot investment,” says Kyle Thompson, product innovation manager at Thomson.

The actuator features a Kollmorgen servomotor and linear guide rails that move a cobot smoothly from one location to another. However, unlike conventional 7th axes, the Movotrak has collision detection functionality similar to a cobot joint. Engineers adjust collision sensitivity settings on a control tablet during setup, and the motor drive and digital I/O manage the collision monitoring and shutdown.

The collision detection system also monitors current continuously, detecting position errors in the motor, and providing comprehensive anti-collision capabilities along the entire 7th axis. The system includes a small reverse-move feature that eliminates pinch points following a stop.

The device integrates seamlessly with many cobot sizes and brands, including Universal Robots (UR), which allows all programming to be done directly through a URCap interface on its teach pendant. All collision monitoring and safeguard logic runs in the Thomson drive, so bandwidth competition with the UR controls is minimal.

Just as cobots can be programmed through a “free drive” setting, engineers can manually set waypoints on the linear track. Engineers manually slide the cobot where they would like it to be in a sequence along the 7th axis and register that with a push button.

Thomson Industries Inc.

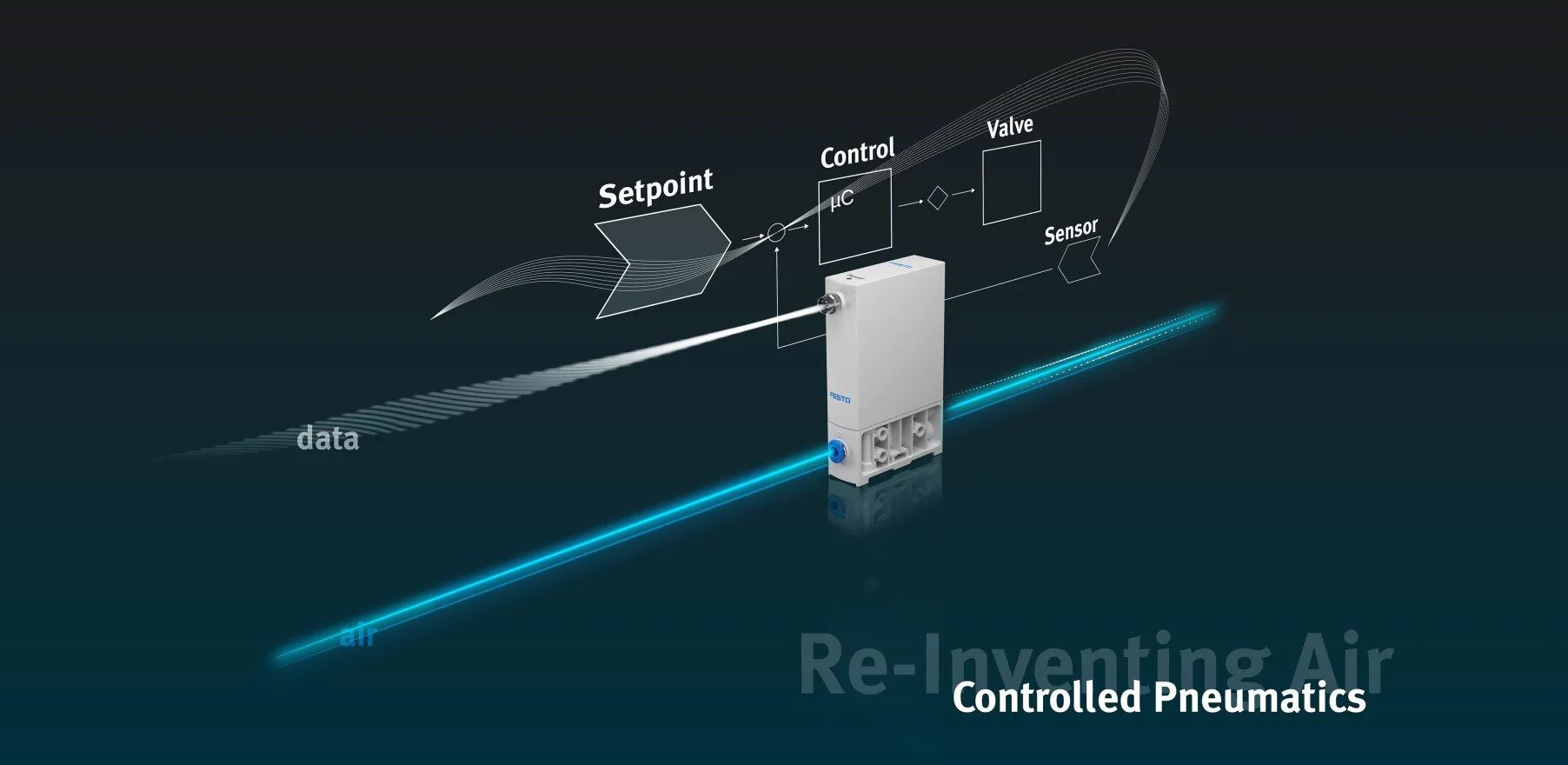

Digital Closed-Loop Control for Pneumatics

Festo introduces Controlled Pneumatics, a digital closed-loop control strategy for delivering energy efficiency, high dynamic response, and precision movement. Controlled Pneumatics is ideal for web tensioning, welding, surface processing, flexible gripping, dispensing, bottle blowing, and diaphragm pump control.

Controlled Pneumatics lowers compressed air usage by up to 50 percent. Precise proportional pressure control also conserves gases used in food and beverage, chemical, and semiconductor processing applications.

Controlled Pneumatic systems are composed of digitally controlled proportional pressure regulators, sensors, high-speed communications, and control algorithms.

Proportional pressure regulators feature piezoelectric valves, which consume 95 percent less energy than solenoid valves. Piezoelectric valves open proportionally for precision control of pressure and flow and are fast acting for highly dynamic applications. Closed-loop control of these valves ensures an accurate, stable and linear flow rate—without hysteresis. Repetition accuracy is rated at ±0.25 percent of the set point. Piezoelectric valves do not generate heat and can be densely packed. Low friction prolongs service life. These valves have a peak particle size per switching cycle of 0.1 micron, which is about five times smaller than proportional pressure regulators that do not use piezoelectric valves. These valves operate silently.

The product range includes the VPPI proportional pressure regulator for high flow-rate applications. The VTEM motion terminal is used for multi-channel control of large and small workpieces. The VEAB low flow-rate proportional pressure regulator is designed for highly precise applications. The VTEP is a compact valve terminal for multi-channel low flow-rate pressure control. It features high precision and dynamic response. These proportional pressure regulators can be used in addition with solenoid valves for hybrid functionality. The VEAB is a proportional pressure control valve for pressure ranges up to 6 bar. The VEFC is a compact mass-flow controller for inert gasses.

Festo

Compact Linear Actuator Is Powerful

The LA33 is a compact and powerful linear actuator for applications that require customized interfaces, fast and silent operation, and the ability to endure harsh and extreme environments. A thorough and demanding testing program ensures that this actuator will provide maintenance-free and long-lasting performance. Stroke length ranges from 100 to 600 millimeters. Maximum load is 5,000 newtons, and maximum speed is 70 millimeters per second.

Part of the company’s IC Integrated Controller range, the LA33 integrates seamlessly with existing control systems in both industrial and off-highway applications. It offers a variety of industrial interfaces for smart and reliable movement. Engineers can choose the universal LINAK I/O interface or select from a comprehensive range of communications protocols, including CANopen, CAN SAE J1939, IO-Link, LIN bus, Modbus RTU, EtherNet/IP, Modbus TCP/IP and PROFINET.

A low-noise gear option makes the actuator’s movement close to unnoticeable, making it suitable for applications where a discreet noise level is important, such as warehouses, yachts and vehicles. A high-speed gear option is also available for applications such as opening and closing doors.

See this company at The ASSEMBLY Show Oct. 21-23 in Rosemont, IL.

LINAK U.S.

High-Thrust Linear Motor Stage Delivers Long Stroke Lengths

The LT170H2 direct-drive linear motor stage is for dynamic applications, such as measurement, assembly and semiconductor fabrication, that require high thrust forces and long strokes. It delivers 260 newtons of rated force and a maximum force of 500 newtons.

Its redesigned linear motor leverages direct-drive technology that is free of mechanical power transmission parts that can otherwise hinder positioning accuracy. The stage also comes with C-Lube linear bearings for guidance. Together, they allow the positioning stage to achieve higher thrust forces and high speeds with precision.

Maximum speed is 3,000 millimeters per second. Maximum stroke length is 2,750 millimeters. The stage is 170 millimeters wide. The stage consumes approximately 48 percent less power than the model.

IKO International