ADDITIVE MANUFACTURING

Nick Allen // Managing Director // 3DPRINTUK // London

Design for additive manufacturing requires a different approach than that for conventional processes.

Design for Additive Manufacturing

Part 2

Komodo Simulations uses AM to make realistic control systems for its helicopter flight simulators. Photo courtesy 3DPRINTUK

As engineers assess how additive manufacturing (AM) can replace or complement traditional manufacturing processes, there will need to be a quantum shift in how to approach the entire design-to-manufacturing process.

Necessarily, this begins with re-evaluating product design. Developments in design for additive manufacturing (DFAM) will drive the uptake of AM as a production technology. This is because DFAM requires a different approach than traditional design for manufacturing and assembly (DFMA). The latter focuses on designing products to reduce manufacturing and assembly costs, while DFAM aims to capitalize on the unique capabilities of AM to optimize a product or component. By applying DFAM, engineers can take advantage of the ability of AM to create complex geometries and reduce part weight.

Of course, AM processes have their own design constraints, as well, which is why specific DFAM skills are essential to successful application of the technology. As with any manufacturing process, there are good designs and there are bad designs. For many engineers, however, this is a leap into the unknown, and it can be a barrier to adoption.

Design Optimization

Whether designing a new product or redesigning an existing one, design optimization should focus on two key goals: topology optimization, to create stronger and lighter parts, and part consolidation, to go from multiple parts to fewer parts or even one part.

Both of these goals are unique to AM, and they cannot easily or cost-effectively be achieved with traditional manufacturing processes. AM can produce components that are either impossible or too difficult or expensive to achieve using injection molding, such as components that are hollow in certain areas or products that require an internal lattice structure. This is possible because 3D printing is an additive process, in which material is added layer by layer and material density can be altered in predetermined areas of the part. As a result, not only can some areas be hollow, but other critical areas can be reinforced. This makes AM a key technology for lightweighting.

Topology optimization uses software algorithms to optimize material distribution within a design. It is a powerful technique for weight reduction, because it removes material where it is not required, while maintaining, and sometimes even increasing, the overall functionality of the part. This often results in designs with complex geometries, something that only 3D printing as a manufacturing method can fulfill.

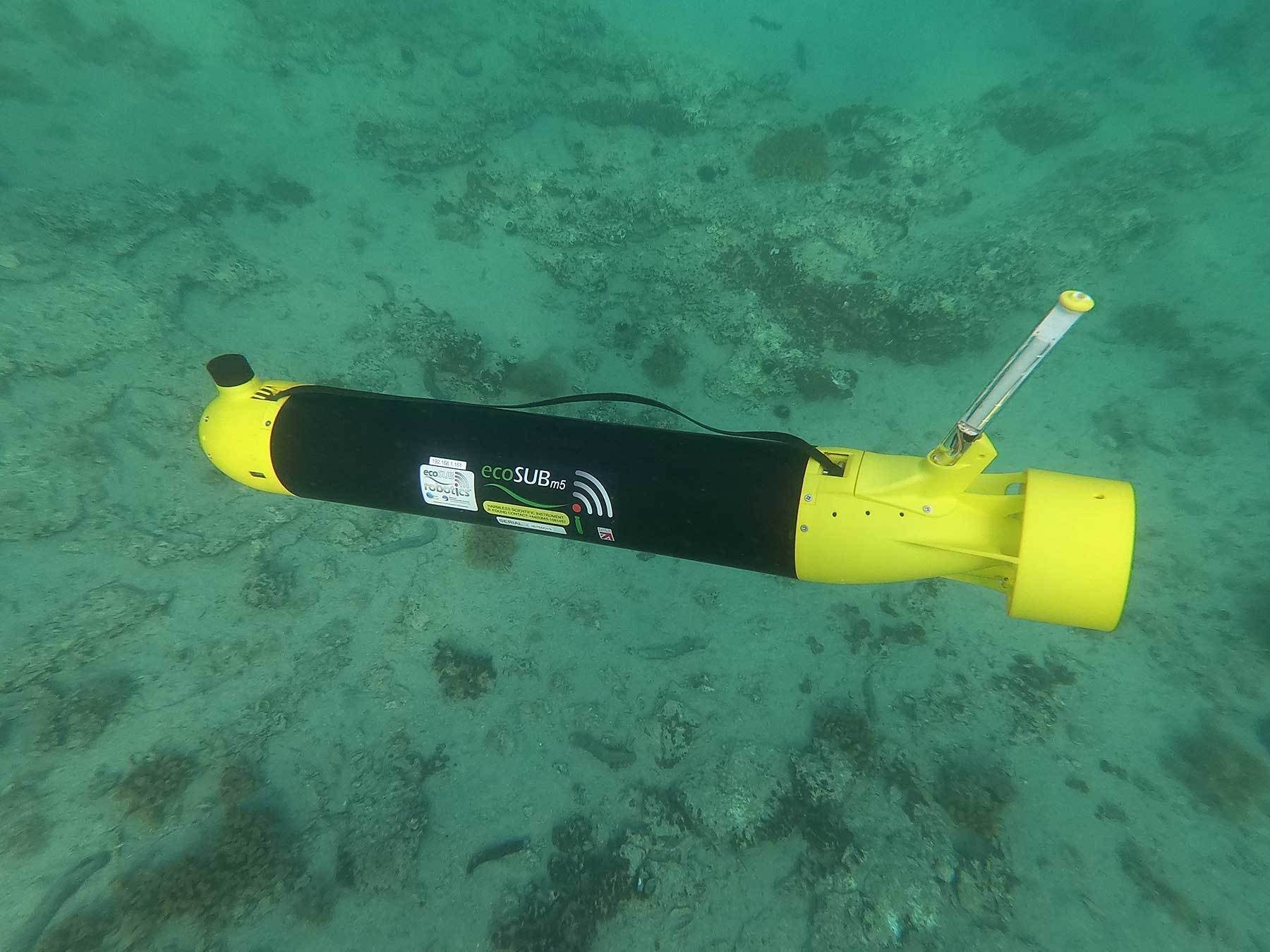

EcoSUB Robotics uses AM to maximize efficiency and reduce costs per part. Photo courtesy 3DPRINTUK

Part consolidation is another advantage of AM. The technology can be used to create complex internal geometries or even complete products that incorporate the functionality of multiple components that cannot be made via conventional manufacturing technologies.

While AM processes are relatively agnostic to increased part complexity, engineers need to understand the limitations and capabilities of the particular process chosen for production, the system-level design intent, and its implications in terms of inspection, validation and postprocessing.

While part consolidation can improve structural performance compared with conventional multipiece assemblies, this may not always be the case. For example, 3D printed materials are directionally weakened, usually in the “build” direction, and this can compromise design intent and ultimate part functionality.

For manufacturers that are assessing the feasibility of using AM for production, there are various considerations that need to be addressed. The learning curve for achieving optimal outcomes for part functionality, cost savings, and time savings can be steep.

As a result, manufacturers can benefit from forming strategic partnerships with experienced AM service providers. 3DPRINTUK has been applying AM technologies for years. We have the expertise to help manufacturers maximize the opportunities of AM and avoid the pitfalls.

Developments in design for additive manufacturing will drive the uptake of 3D printing as a production technology. Photo courtesy 3DPRINTUK

Our customers have learned this first-hand. For example, ecoSUB Robotics used AM to maximize efficiency and reduce costs per part. In addition, the company has benefitted from the ability to customize designs for individual clients.

Komodo Simulations developed realistic control systems for its line of helicopter flight simulators for home and professional use. In the past, these control systems consisted of many parts made with traditional manufacturing methods. We showed the company how to use AM to print the assembly as a single part, which reduced costs significantly. In addition, AM allowed for hollowed-out internal parts and little or no limitation on the design of complex curved parts. The capability to produce high surface detail also means that textured grip surfaces can be included in the design.

DFAM provided aerospace supplier Kongsberg with new opportunities, too. According to the company, “By deciding to 3D print a pivotal part in a new design right from the word go, we were able to shrink the size, while integrating features and functionality that are simply not available through other manufacturing methods.”

For Brushtec, a manufacturer of brushes for cleaning equipment, AM has unlocked a new level of innovation and enabled the company to “design complex parts and not be restricted by the limitation of standard machining.”

AM enables engineers to look past the constraints that exist around traditional design methodologies. In so doing, there is much greater freedom of design in terms of complexity. Parts can be produced using AM that are more ergonomic and which incorporate multiple parts and features which would be impossible or prohibitively expensive to achieve via the fabrication of highly complex tooling required for injection molding.

The opportunities are endless. But, there are caveats. AM for production applications does have its own constraints. In part 3, we will consider these in more detail and highlight how to work around them.

Editor’s note: This is the first of a three-part series about design for AM. Part 1, which appears in the October issue, covered the history and impact of AM. Part 3 will explore the intricacies of designing specifically for AM, the advantages it offers over traditional manufacturing processes, and the pitfalls to avoid to achieve the most successful outcomes.

ASSEMBLY ONLINE

For more information on additive manufacturing, visit www.assemblymag.com to read these articles: