Test and Inspection

Adding AI inspection on an assembly line can improve product quality. Photo courtesy Matroid Inc.

AI

Artificial intelligence technology can streamline inspection applications.

Augments Machine Vision

Austin Weber // Senior Editor // webera@bnpmedia.com

Artificial intelligence technology is being deployed in numerous manufacturing applications. Engineers are using AI to analyze production data, come up with new designs and guide robots. However, one of the best use cases for the technology is to aid visual inspection.

Machine vision systems powered by AI can analyze process parameters and detect anomalies in materials and products. They provide operators and engineers with real-time reporting on critical activities and events.

“A great deal of assembly still requires a human, whether that’s fully completing a task or making a decision as part of an automated process,” says Ed Goffin, vice president of product marketing at Pleora Technologies Inc. Its Vaira platform, which integrates machine vision cameras, lighting and processing software with AI-based inspection and traceability apps, enables manufacturers to automate and upgrade error-prone assembly processes.

“More than 70 percent of manufacturing processes in North America rely on a human decision,” explains Goffin. “We are good at making decisions, we are easy to train and we can adapt when situations change. However, when we get tired or distracted, we tend to make mistakes.

“Adding AI inspection on an assembly line ensures those human decisions are consistent, reliable and trackable,” Goffin points out. “AI-based visual inspection and checklist tools can help guide an assembly process and provide real-time verification that steps are completed while ensuring quality.

“We see a lot of interest in AI decision-support for electronics assembly,” notes Goffin. “For smaller runs or customized applications, it can be too expensive and time-consuming to set up full automation. With a combination of AI and vision, operators are guided through what are often complex assembly and verification steps.

“[One of our customers] has been able to use AI-based object detection to reduce final inspection from over four minutes to less than 30 seconds,” claims Goffin. “The ability to capture and save images from these manual processes also provides a complete record for traceability and compliance.”

“Manufacturers can leverage AI to improve the accuracy, consistency and speed of parts inspection on their assembly lines, while simultaneously improving quality control,” adds Maurice Liddell, national manufacturing and distribution industry leader at BDO Digital, a technology consulting firm that primarily works with mid-sized companies. “AI systems leverage inputs from computer vision, lasers and other sensors to ‘see’ parts through cameras, allowing robotic systems to inspect parts.

“[The technology] can also use laser distance sensors to perpetually scan for errors across a vast, fast-moving production line,” explains Liddell. “Because many quality assurance tasks are highly repetitive, an AI system that has been taught which defects to look for can perform these tasks, allowing employees to focus on higher-value tasks within the plant.”

While AI on assembly lines has the potential to improve efficiency, Liddell says it’s important to evaluate return on investment within the larger context. “The less repetitive and homogeneous the task, the more a manufacturer will need to invest in training the AI system to properly execute,” he points out.

For example, a furniture factory may find that a worker assigned to evaluate fit and finish may only be able to flag 90 percent of errors. Even if a system equipped with computer vision and laser distance sensors could flag 99 percent of defects, the cost and complexity of training an AI system to correctly spot minuscule flaws may make a digital quality improvement strategy uneconomical. In these cases, jobs that require greater dexterity, creativity and experience may simply be better for a human to perform from both a cost and quality standpoint.

“In addition to direct inspections, AI can be used to train human inspectors to perform inspection duties to attain higher accuracy rates,” says Liddell. “A [workstation] that uses computer vision to inspect parts along with a [person] can enable the human inspector to gain a better understanding of what is in compliance and what is not.”

Beware of the Hype

Artificial intelligence is one of the biggest automation trends to hit the manufacturing world since robots first appeared in the 1960s. However, the term is often misused and misunderstood.

“AI is very tempting to use, because it’s the hot buzz word that everyone wants to hear today,” says David Dechow, vice president of outreach and vision technology at Landing AI. “In fact, it’s the most over-hyped technology in industrial automation in decades.

“I prefer to refer to AI as ‘deep learning,’” explains Dechow. “Deep learning has become recognized as a useful tool in the integration and implementation of industrial machine vision systems.

“With its ability to leverage artificial intelligence to ‘learn’ from continual analysis of data-centric models, deep learning provides value in certain industrial quality inspection applications, including defect detection and assembly verification,” Dechow points out.

“Adoption of deep learning for machine vision applications has been somewhat slow, because of practical problems including the challenges of on-line imaging and, most importantly, the potentially small data sets that deep learning technology could not handle,” claims Dechow.

“AI can be a useful tool in automated inspection for discrete analysis of images,” says Dechow. “It’s most effective in applications where the variability of the parts to be inspected is subjective. For instance, detecting surface anomalies that are hard to define, such as scratches on metal.”

According to Dechow, AI isn’t for everyone. He believes that engineers need to decide on a case-by-case basis whether the technology is the most efficient, the cheapest and the easiest to use for a particular application.

Artificial intelligence technology enables manufacturers to automate and upgrade error-prone assembly processes. Illustration courtesy Pleora Technologies Inc.

“One misconception about AI is that it’s a standalone technology,” warns Dechow. “Another misunderstanding is that it’s automatically easy to use; in many cases, it isn’t.

“Deep learning will continue to be valuable for specific inspection tasks,” predicts Dechow. “I do not expect huge, dramatic advances, however, for applications in automated inspection near term.

“I believe the best products in the immediate future will be those where a systems provider has incorporated deep learning for specific inspections (perhaps even with pretrained models) that work alongside other vision tools and algorithms,” says Dechow. “I've long called this a ‘hybrid’ system.”

Like many other types of trendy technology, some small manufacturers are turned off by AI, because they believe that it’s too complex and too expensive.

“Deep learning for automated inspection actually does seem to be expensive and to many, the reasons for the cost are difficult to understand and subsequently difficult to justify relative to the benefit of the technology,” notes Dechow. “[AI has not always] been the silver bullet that provides fast and easy solutions that work reliably.

“In many cases, it is complex and hard to implement relative to the benefits, cost and results,” claims Dechow. “That said, deep learning actually is readily available at reasonable cost from some vision product providers. But, even then, the complexity may be beyond the reach of a small company.”

To address those issues, some visual inspection technology suppliers are focusing on usability.

“AI has traditionally been seen as complex and expensive,” says Pleora’s Goffin. “In the last year, there’s been a real push toward making it easier to train and deploy more advanced AI inspection skills.

“That includes low-code development tools, right down to a more app-based approach to AI deployment that provides [engineers] with templates for common AI and digitization requirements that they can customize for their own workflows, easily train and deploy into production,” explains Goffin.

“One of the biggest challenges around AI model development has been the number of good and bad images required to get started,” notes Goffin. “Now, with an app-based approach, a manufacturer first deploys vision-based inspection to detect errors, and uses operator input to transparently train an AI model that will quickly begin providing decision support.”

Vaira’s visual inspection app now includes AI-based object detection and classification skills that can be integrated with assembly checklist and work instructions. An operator follows digitized instructions that clearly guide product assembly step-by-step, while AI and machine vison automatically verify quality.

The app can check that the correct component has been used in an assembly and confirm that it is in the proper position. If a defect is detected, the operator can’t move to the next assembly step until the error is corrected.

Adding product tracker app capabilities, product images and operator notes are captured and stored to a manufacturer’s ERP or MES system for compliance, traceability and continuous improvement initiatives.

“I think we’re crossing a threshold from education to deployment,” says Goffin. “Two years ago, most of our conversations with manufacturers were geared toward educating them on the differences between machine vision and AI.

“Today, there’s more understanding on the benefit and limitations of AI, and a real focus on deploying new technologies to solve problems,” claims Goffin. “For companies with established vision inspection, they are looking at AI to improve results. In particular, they want to reduce the number of false positives that can happen during machine vision inspection.

“There are also a number of manufacturers that have never really deployed vision looking at AI and digitization as a way to solve an error-prone process and gather data to guide an automation strategy,” adds Goffin.

Inspection System

Manufacturers are leveraging AI to improve the accuracy, consistency and speed of parts inspection on their assembly lines. Photo courtesy Flex Ltd.

AI in Action

Artificial intelligence technology is being used by a variety of manufacturers looking for new ways to improve efficiency and productivity. Visual inspection applications include automotive parts, consumer products, electronics and medical devices.

One company that has successfully harnessed the technology is Lexmark International Inc., a leading manufacturer of laser printers and imaging products. Its engineers recently developed an in-house system called Optra Edge Visual AI that is capable of object detection, classification and instance segmentation.

“As with any manufacturer, significant time and effort goes into quality control,” says Sudhir Mehta, global vice president of Optra engineering and product management. “We had our best engineering talent come up with an innovative solution for a long-term challenge. Using AI, our fundamental idea was to replace human eyes with technology.

“Through Optra Edge Visual AI, we are able to solve several inspection challenges, including inspection inconsistency, the cost and time constraints of human inspectors, quality issues and accidents,” claims Mehta.

“Manually identifying defects is often prone to human error,” explains Mehta. “There are also significant costs associated with human inspectors. Particularly, the difficultly in managing staff magnifies itself when there are more products sitting in the pipeline.

“With Optra Edge Visual AI, we saw marked improvements—a 40 percent boost in inspection speed, identification accuracy of 99 percent and a 99 percent improvement in traceability,” says Mehta. “To reach nearly 100 percent is unprecedented and unimaginable.”

According to Mehta, AI-powered technology is a natural fit for visual inspection. “It is active and highly accurate 24/7, 365-days-a-year, which is ideal for a production line that is constantly running with a lot of ebb and flow,” he points out.

Lexmark recently used AI technology to develop an in-house system that solves several inspection challenges. Photo courtesy Lexmark International Inc.

“[We] can monitor all production processes in real-time,” adds Mehta. “Any defects are automatically detected by the AI-enabled application, issuing instant alerts through the integrated manufacturing systems. This can be scaled and implemented consistently—and simultaneously—across multiple production lines. The [system] can easily be trained to adapt to specific use cases and local needs.

“In addition to accuracy, AI-enabled [systems] are cost-effective compared to human visual inspection,” explains Mehta. “An AI-powered system can monitor [operators] to uncover new ways to work efficiently and safely. It can also feed them alerts to inform them about any complex quality-based decisions they need to make. AI absolutely empowers efficiency and helps [assemblers] adapt to strategic planning objectives.”

Optra Edge Visual AI proved to be such as game-changer for Lexmark that the company has decided to market it to other manufacturers. The system is guided by neural network models that are trained to conduct visual inspection and quality control on assembly lines.

“This is all done at the edge on the manufacturing floor to enable engineers to rapidly adapt it to their needs,” says Mehta. “As printers roll off a conveyor, we analyze front covers and model badges, count and verify photoconductor drums, and manage pallet distribution.

“We integrated Optra Edge Visual AI into our existing assembly line infrastructure, which includes cameras, displays and manufacturing execution systems,” Mehta points out. “[We] realized a return on investment within five months of implementing this new system.”

Another company that’s bullish on AI technology is Flex Ltd., a $26 billion contract electronics manufacturer with more than 1,000 customers around the world. To ensure consistent quality, it relies on people to inspect printed circuit boards and other products.

However, as product demands and cycle times have increased, it has become increasingly difficult for human eyes to detect anomalies. To combat this challenge, Flex recently implemented a detection system using deep neural networks to identify flaws that are difficult to see with traditional vision systems.

Vision Inspection Technology Improves EV Battery Quality

Adhesive dispensing plays an important role in assembling electric vehicle battery packs. However, applying sealant to enclose covers and lids is a major challenge for manufacturers.

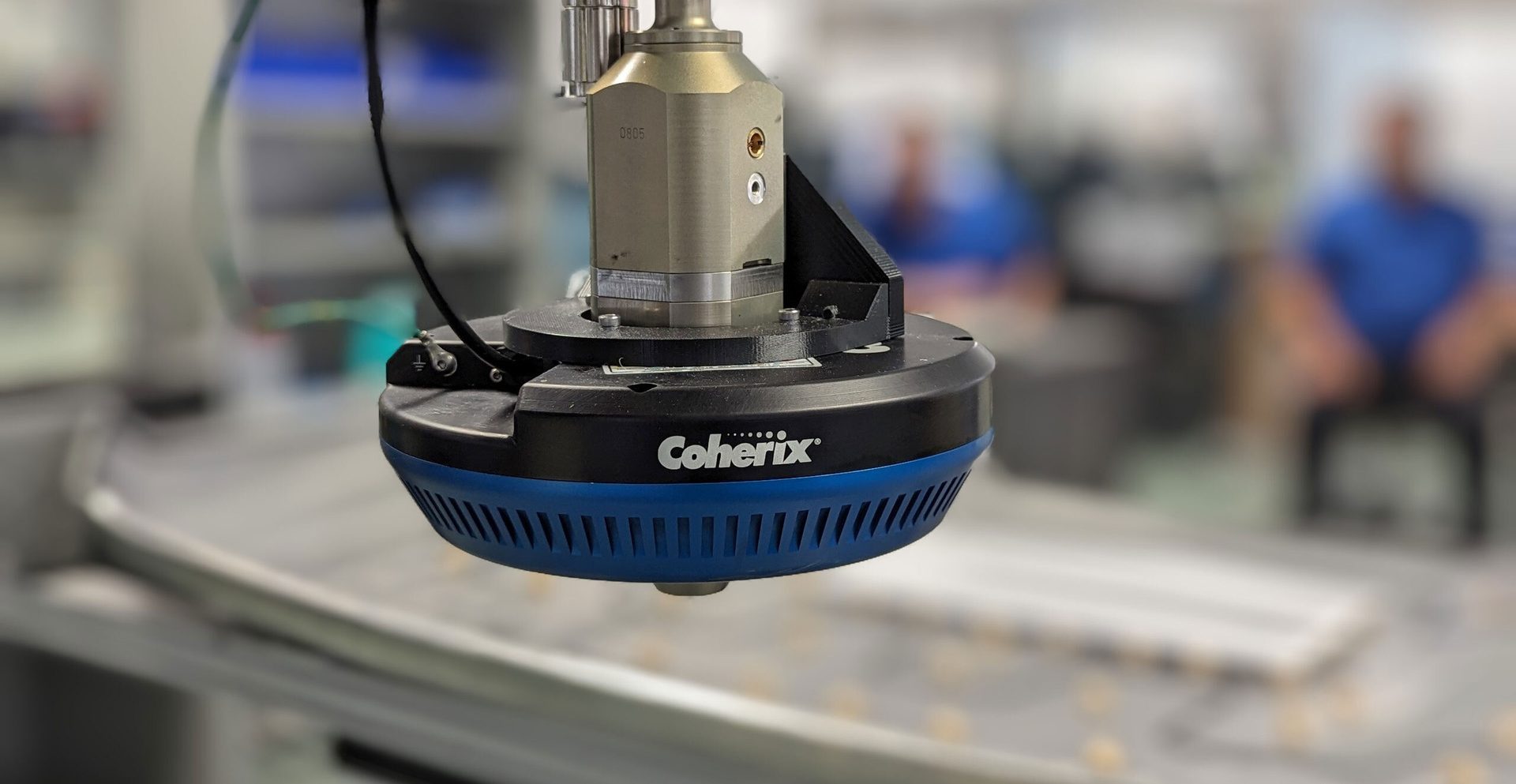

To address the issue, Coherix Inc. recently developed an inspection system that uses artificial intelligence and machine vision technology to ensure that the correct amount of adhesive is applied during the battery assembly process. The company has also created software capable of automatically adjusting the application of adhesives at line speed to improve quality, cut downtime, and reduce labor and material costs.

Coherix developed adaptive process-control systems for the autonomous application of adhesives using laser-based sensors that see, understand and proactively correct applications to minimize errors and maximize performance.

Coherix 3D is an inline inspection system that features a self-contained device that mounts around a dispensing nozzle to provide a 360-degree view of the adhesive bead.

The company’s recently introduced Adaptive Process Control technology proactively corrects variations on-the-fly, which reduces downtime, eliminates waste and improves quality.

“The automotive industry is moving at light speed in its development of battery technology,” says Juergen Dennig, president of Coherix. “The growth in EV sales puts a spotlight on battery manufacturing processes needed to properly seal lithium-ion battery cases and covers to achieve optimal performance, safety and quality.”

This device uses laser-based sensors to minimize adhesive dispensing errors and maximize performance. Photo courtesy Coherix Inc.

According to Dennig, adhesives can cost up to $180 or more per gallon. The use of his company’s technology has been proven to reduce the amount of sealant used in the assembly of battery packs by up to 30 percent. For an assembly line producing 300,000 batteries per year, the annual savings could total up to $4 million.

Dennig says many battery manufacturers today rely on inefficient 2D camera systems to monitor the application of adhesives and sealants. Those older systems are affected by ambient light, unable to detect adhesive volume and cannot monitor other critically important sealant-application data, such as bead shape, center height or cross-section measurements.

“Unlike 2D and other inspection systems, [our] quality control systems can measure and adjust the amount of sealant used in robotic dispensing processes and ensure that critical center-height and volume specifications are met,” claims Dennig.

“Adaptive process control and 3D-vision technology will be the quality control standard for sealing battery closures in the not-to-distant future,” predicts Dennig. “Our technology is rapidly gaining acceptance not only in North America, but in Asia and Europe as well.”

In addition, the company has developed tools that help eliminate unscheduled downtime and allow sealant robots to run at maximum speed.

“By investing in AI and machine learning applications, as well as other Industry 4.0 technologies, we are empowering our employees to make real-time decisions that ensure our customers’ products are getting to market faster, product volumes are met and that we are achieving world-class quality,” says Murad Kurwa, vice president of advanced manufacturing engineering at Flex.

“It becomes more difficult for the human eye to identify and flag issues,” notes Kurwa. “Inspection criteria have also become increasingly wide-ranging, covering screws, wires, labels and defects to vital components. And, flaws become even more challenging to detect toward the end of a shift, due to visual fatigue.

“[Our new] system can detect issues that are very difficult for the human eye to see,” claims Kurwa. “And, it continues to learn, get more intelligent and catch more errors over time.

“By using AI-based detection systems, [we] can identify defects and quality issues in real-time with more accuracy and precision,” Kurwa points out. “AI can also be used to give early warning signals based on trends or anomalies, which is particularly helpful for a high-speed process in real-time where statistical process control may be limited or fall short.

“These applications allow workers to optimize the manufacturing process, which results in outcomes like reduced waste, as well as increased yield and quality assurance,” says Kurwa. “In addition, AI applied to inspection can improve upstream processes and create a closed-loop control methodology.”

Since the system was implemented last year, it has improved product yield by 97 percent and resulted in overall efficiency improvements of more than 30 percent. Payback from the initial investment was less than one month.

“The new tool also helped [us] reduce scrap, optimize factory floor space by eliminating legacy inspection stations and improve morale with inspection staff,” claims Kurwa. “The former inspection employees were provided career advancement opportunities managing the new tech, rather than focusing on the monotonous inspection process.”