ASSEMBLY LINES

AI-Driven System Could Transform How Factories Operate

CHARLOTTESVILLE, VA—Engineers at the University of Virginia have developed an AI-driven system that could transform how factories operate. Using Multi-Agent Reinforcement Learning (MARL), they created a more efficient way to optimize manufacturing systems, improving both speed and quality while reducing waste.

The system integrates AI agents that work together to optimize production processes. By coordinating multiple agents to manage tasks in real time, it adjusts automatically, learning and improving performance over time. The research was conducted in collaboration with General Motors, which provided real-world applications for the AI system.

“We are addressing the complexity of modern manufacturing,” says Qing “Cindy” Chang, Ph.D., a professor of mechanical and aerospace engineering at the University of Virginia who is heading up the project. “Instead of optimizing individual processes in isolation, our system looks at the big picture, coordinating everything at once.

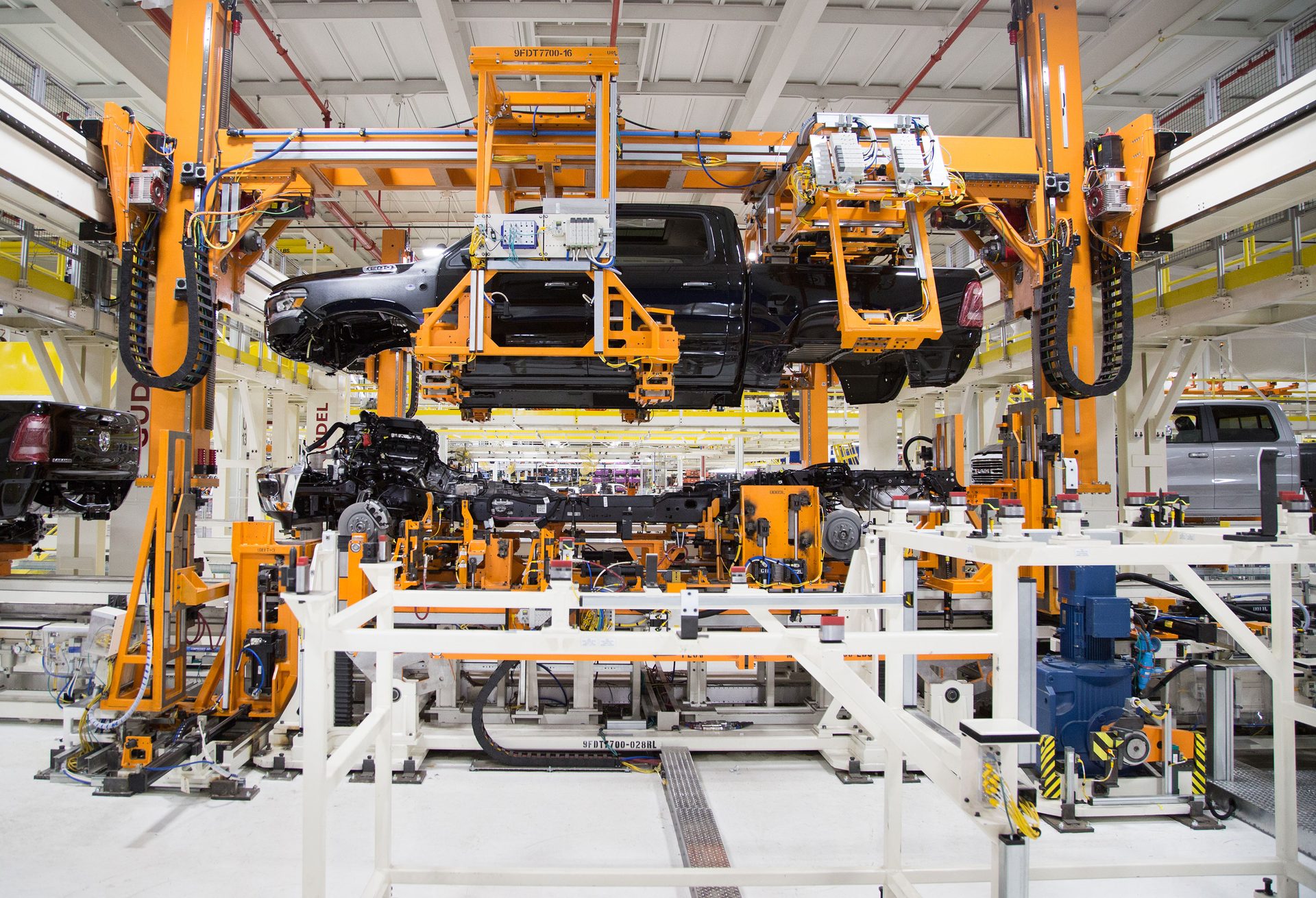

By integrating system- and process-level parameters, a new AI-driven system can optimize yields and dynamically adapt to changes, such as machine breakdowns or production adjustments. Photo courtesy General Motors

“The result is smarter, faster and more adaptable manufacturing,” claims Chang. “This breakthrough could lead to faster production, reduced downtime and better-quality products across industries, from automotive to electronics.”

Special algorithms allow the system to account for both the physical constraints of machinery and unpredictable production disruptions. By integrating system- and process-level parameters, the AI tool can optimize yields and dynamically adapt to changes, such as machine breakdowns or production adjustments, without human intervention.

According to Chang, it’s a major leap forward in smart manufacturing. She believes the AI-driven control system could establish new benchmarks for manufacturing efficiency, particularly in complex, multistage production environments such as automotive assembly plants.

“In addition to improving productivity, the system offers significant economic and environmental advantages,” says Chang. “By reducing waste, minimizing downtime and lowering energy consumption, manufacturers can achieve substantial cost savings while shrinking their environmental footprint. The technology presents a powerful step forward for both industry and sustainability efforts.”

More Manufacturers Are Investing in XR Technology

NEW YORK—Manufacturers in a variety of industries are slowly adopting extended reality (XR) technologies like smart glasses and virtual reality headsets, according to a recent survey conducted by ABI Research. More than two-thirds of manufacturers claim to have some level of XR activity.

“The value of XR to organizations has been known for years, especially in areas like training, remote workforce enablement and collaboration,” explains Eric Abbruzzese, research director at ABI Research. “However, the barriers to that value have also been well-known and remain. Device cost, integration concerns and confusion around offerings are most common.”

While XR is in the early stages of adoption, Abbruzzese says the technology can improve equipment performance and quality levels. Other benefits include remote maintenance, interactive training and reliable knowledge capture or sharing.

Manufacturers in a variety of industries are slowly adopting extended reality technologies like smart glasses. Illustration courtesy ABI Research

At the same time, people and process barriers are common pain points around XR cited in the survey. A lack of time to plan, along with a general lack of expertise in XR, has delayed potential investment and adoption. Both were ranked highly among respondents as barriers.

“The XR market has seen plenty of ups and downs over the past decade, which has hindered trust and understanding in the market despite proven value,” notes Abbruzzese. “A lack of clarity among available platforms and paths to market hold back potential adoption.

“However, the growth of related digital transformation technologies, especially digital twins and machine vision, is a boon for XR and vice versa,” says Abbruzzese. “Over time, a more holistic view of visual workforce enablement will take hold, rather than a focus on individual technologies, and XR will be an increasing portion of that offering.”

Honda Hosts Students on National Manufacturing Day

MARYSVILLE, OH—Honda Motor Co. recently opened its doors for more than 1,700 students at 11 U.S. production facilities. It was part of an effort to build interest in manufacturing and promote career opportunities.

Students and teachers had an opportunity to meet Honda employees and participate in hands-on activities such as building a model car on a simulated assembly line, virtual welding and a vehicle painting simulation, The events took place at the automaker’s factories in Alabama, Georgia, Indiana, North Carolina, Ohio and South Carolina.

Honda facilities throughout the U.S. recently invited students to get an up-close, hands-on look at manufacturing. Photo courtesy Honda Motor Co.

“Honda has a proud tradition of celebrating Manufacturing Day (the first Friday in October), and associates love to share their passion for creating things by providing students with an up-close look at modern manufacturing,” says Meredith Reffey, workforce partnerships leader at American Honda Motor Co. “We take Manufacturing Day very seriously, because it offers a fantastic opportunity to inspire the next generation to explore careers….”

Students toured the facilities to learn how technology, automation and teamwork are harnessed to build engines, transmissions and vehicles. Each participating Honda plant featured immersive experiences for students that were unique to their locations and the products they build.

For instance, at the automaker’s transmission plant in Tallapoosa, GA, visitors had an opportunity to try their hand at securing a bolt and interacting with a robot.

Gearbox Reassembly Project Addresses Sustainable Manufacturing

SÖDERTÄLJE, Sweden—Scania AB, a leading European manufacturer of trucks and buses, is installing remanufactured gearboxes in new vehicles at its flagship assembly plant here.

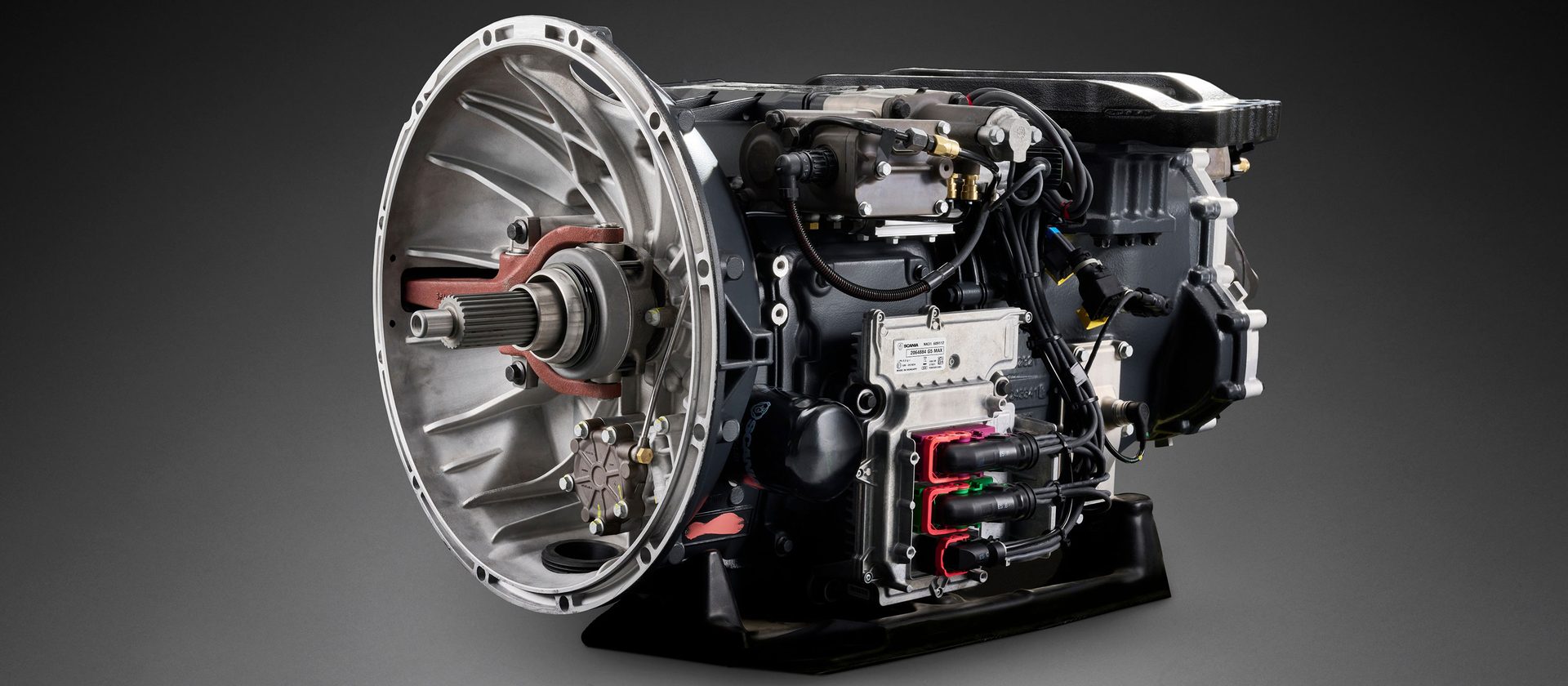

The components were subjected to the same rigorous inline quality and function tests as gearboxes that are made from entirely new parts. They were assessed on the same test rig used for new ones, with monitoring of some 100 quality and function parameters. The gearboxes passed all tests and were confirmed as being “as good as new.”

“This remanufactured gearbox is a compelling example of how the manufacturing of heavy vehicles can become more sustainable, circular and efficient, while still retaining the highest quality standards,” says Fredrik Nilzén, head of sustainability at Scania.

This remanufactured gearbox consumed 50 percent less material and 45 percent fewer carbon emissions vs. making a brand new component. Photo courtesy Scania AB

According to Nilzén, the production process showed tremendous environmental advantages. “While replacement rates during gearbox remanufacturing can vary between roughly 10 percent to 100 percent depending on wear-and-tear history, this particular gearbox consumed approximately 50 percent less material and caused 45 percent fewer carbon emissions compared with gearboxes made only with new components,” he points out.

Remanufacturing, which involves the reuse of old parts to create new products, is viewed by the automotive industry as a promising strategy for achieving climate goals and supporting the transition toward a circular economy. It also addresses increasing resource scarcity issues.

However, Nilzén says the wider adoption of the process requires vehicle manufacturers to integrate remanufactured components directly into the production lines of new vehicles, rather than using them separately in sales to the aftermarket.

“This research provides the first evidence to support the argument that it is feasible to envision future manufacturing organizations seamlessly integrating manufacturing and remanufacturing operations to develop circular manufacturing systems that consume fewer resources, produce fewer emissions, and cost less without compromising quality and performance,” says Farazee Asif, assistant professor of manufacturing and metrology systems at KTH.