EMH Crane Lifts Animal Care

Prior to the EMH Crane installation at Zoo Atlanta, when large animals such as an elephant needed emergency care, the Zoo had few options. One option was using a fixed hoist. Unfortunately, that only worked when the elephant was situated close to an exact spot under the hoist where the elephant could be easily accessed.

During construction of Zoo Atlanta’s Zambezi Elephant Center, the decision was made to install an overhead EMH 7.5-ton overhead crane system with the new EG Series Hoist. The EMH crane covers the entire facility with a span of 70 ft. and a runway length of 128 ft. A hoist hook height of 25 ft. was considered perfect for emergency elephant lifting. The EMH Crane was also provided with NEMA 4 enclosures for water spray considerations, and a radio remote control that allows zoo personnel to operate inside or outside the elephant enclosures. According to Zoo Atlanta’s Lead Elephant Keeper, “Since African Elephants are tree-top grazers in their natural habitat, the EMH Crane installation also provides an important side benefit. With push-button and radio control, we can move the food around, engaging the elephants to enjoy a better experience while providing them with a little exercise.”

Single Axis Weld Positioning System for the Defense Industry

In the demanding and critical realm of the defense industry, precision and customization are crucial. Motion Index Drives manufactured an exceptional solution specifically for a complex laser descaling project on heavy military vehicles.

At the core of Motion Index Drives’ solution was a system designed to eliminate backlash at the output of rotation. This feature ensured uninterrupted operation and maintained the integrity of the vehicle surfaces being treated.

The robust VTMF3010 trunnion was a key component, known for its strong load-handling capacity and precise positioning. It included an auxiliary axis robot motor for accurate alignment and control, as well as a safety locking mechanism to secure loads even in case of motor brake failure.

Motion Index Drives engineered a system with an oversized linear bearing setup featuring four parallel linear bearings. This design provided the necessary flexibility to accommodate different sizes of military vehicles while maintaining high precision and stability.

Motion Index Drives solution was tailored to meet the specifications of the defense application so the system could seamlessly integrate into the existing workflow. The integration of the VTMF3010 trunnion and the auxiliary axis robot motor provided a dual-system approach, delivering both robust load handling and precision alignment.

WEISS North America, Inc.

888-WEISSNA (888-934-7762)

info.us@weiss-world.com

Multipurpose Flexibility from WEISS

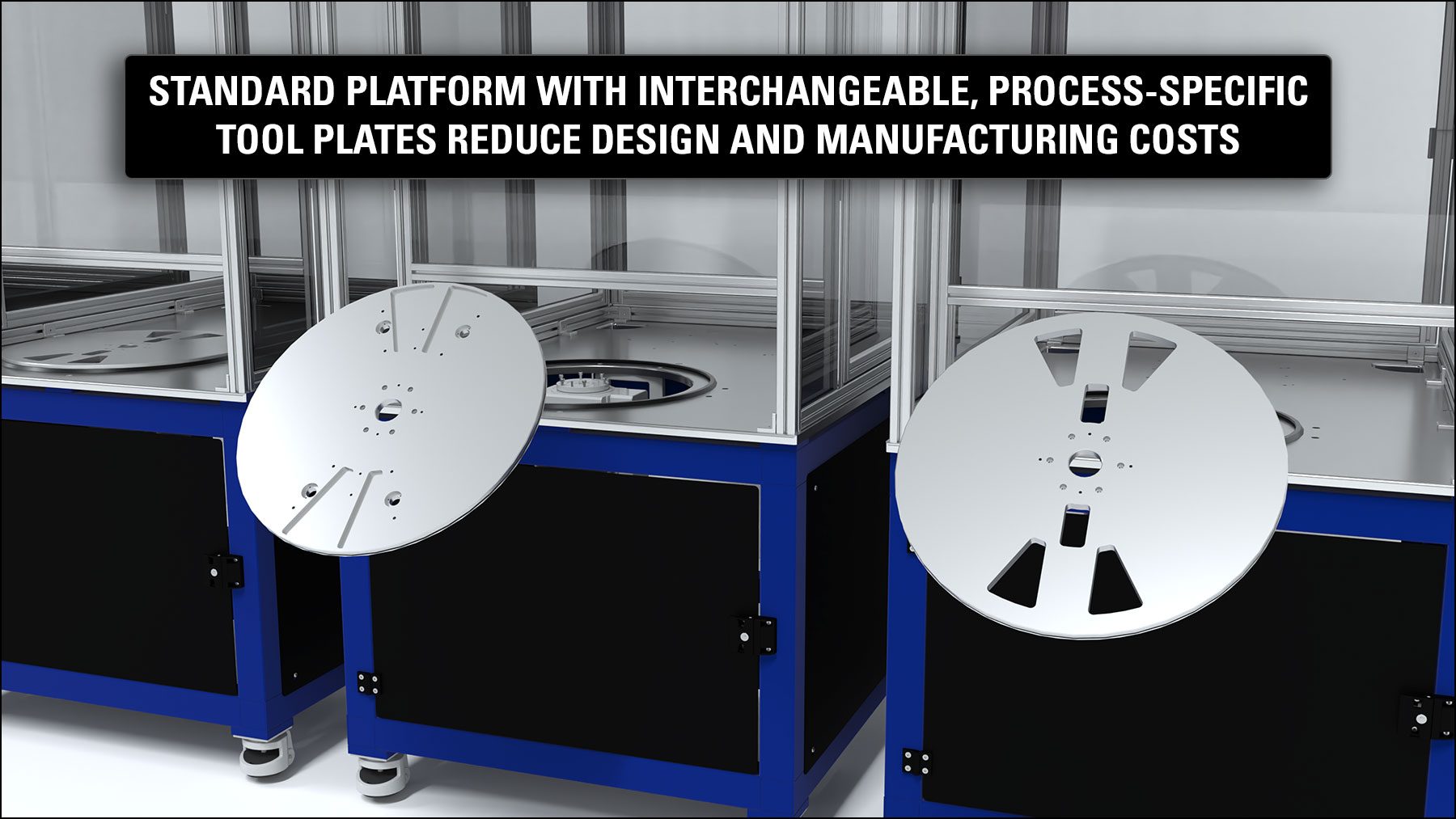

A consumer goods manufacturer recently decided to standardize on multipurpose assembly chassis with a flexible tool plate. Twenty chassis will be purchased as this customer standardizes and updates their assembly cells. Together with the customer’s in-house build team, WEISS provided custom-designed chassis with two tool plate variations.

Each chassis features a two-station TC120 indexer, a welded base, aluminum base plate, and aluminum tool plate with clear anodized finish, leveling plates with casters, aluminum side panels and lockable, hinged door, an aluminum indexer mount plate and extruded aluminum guarding with hinges and latches from Industrial Profile Systems, a wholly owned subsidiary of WEISS North America.

Initially contacted to provide the 2-station TC120 rotary indexers while the customer sourced other suppliers for the chassis, guarding, hardware, and other components of the design, WEISS proposed a single-source solution designed around proven and reliable WEISS automation components and value-added services. This provided the customer a simplified vendor sourcing/vetting process, proven platforms and components, faster time to completion, reduced lead time and overall cost savings due to economies of scale.

To learn more about WEISS, please visit www.weiss-world.com or call one of our automation pros today at 888-934-7762.

Promess Inc.

810-229-9334

promess@promessinc.com

Tailored Electric Press Work Stations

The Promess Electric Press Work Station is a stand-alone unit with an integrated Promess Electro Mechanical Assembly Press (EMAP). The EMAP is a programmable motion-controlled ball screw press with integrated motion control and monitoring. Promess offers 33 press sizes with capacities ranging from less than an ounce to over 200,000 pounds. The Work Station is designed to meet your specific application needs, and Promess offers various standard floor and table top stations to fit your needs.

The Work Station provides a mobile and readily accessible foundation for assembly, test, and lab applications. Being fully electric and energy-efficient, it also contributes to a cleaner work environment, which is not possible with traditional workstations.

To find the perfect Work Station configuration for your application, schedule a visit to the Promess facility or send in your parts for assessment. There is a range of Work Station configurations available on-site for viewing, and the Promess Process Development Center can help validate your process. Contact Promess today for more information on the Electric Press Work Station.

Wire Harness Benches Increase Production.

Tolerances have to be consistently tight when you’re assembling wire harnesses for a jet fighter – 1/8 of an inch over 32 feet to be exact. Workbenches that can’t accommodate such tolerances would be, well, intolerable.

That’s the problem that a jet manufacturer faced when they determined that they needed to upgrade their facility. They were using pieces of plywood on A-frames for the assembly. This not only affected tolerance levels but also led to stress, strain and fatigue.

The jet fighter manufacturer found a company that could deliver what they were looking for in Proline. A leader in ergonomic workbenches. A company renowned not just for its rugged, technologically advanced workbenches, but also for its ability to “think on the fly” and produce, application-specific solutions, Proline met all of the jet manufacturer’s specs.

Thanks to the range of easy vertical movement provided by the Pro-Line benches, along with tilt, all sections of the wire harness are always within easy reach. Since this initial installation, this jet plane manufacturer is currently in the process of expanding its operation with additional Pro-Line workbenches. Clearly they are more than satisfied that they have harnessed such precise, ergonomically sound and productivity-enhancing workbench solutions.

Your customers want their product fast

To meet the heavy demands of one of their most significant customers, the General Motors EV Plant in Detroit, Android Industries turned to Rhino Tool House to get the right tool solutions quickly—in other words, fast.

In record time, Rhino tapped into their partner network to find a unique fix for Android, helping them solve their immediate need while improving their operations for the future.

The Rhino solution included three state-of-the-art mobile assembly carts equipped with advanced worker guidance software, high-precision DC assembly tools, and intelligent torque wrenches. After integrating the carts into Android's MES system, they produced the parts quickly and shipped them to GM with full certification.

Android was able to deliver for GM on time while establishing a new efficiency and quality standard for their future manufacturing.

Don’t let frustrating delays and limited solutions hold you back. Call Rhino Tool House today and get more from your manufacturing

Buckeye Electrical Streamlines Production with Schleuniger

Buckeye Electrical is a family-owned custom wire harness and cable assembly manufacturer located in Botkins, OH. The company strives to offer its customers high-quality products and recognizes the value of efficient, reliable equipment.

After President Kevin Platfoot noticed that outdated machinery and manual processes were hindering precision, efficiency, and turnaround, he took decisive action to research and invest in new equipment.

With assistance from Schleuniger Sales Representative Bruce Moore, Platfoot determined the MultiStrip 9480 and PowerStrip 9580 would help streamline the processing of Buckeye's primary range of cables, including 8–18 gauge hook-up wire and coax multiconductor, and battery cable.

Since modernizing, Platfoot reported, "We [now] process around 12,000,000 feet of wire per year using three cut and strip machines, which would have been unfathomable before.” He also commended Cayman, Schleuniger's cut and strip software, for its seamless usability and file sharing.

Another noted improvement is the Multistrip 9480 and Inket printer integration, which increased marked wire output by 50%.

Overall, restructuring has been game-changing, and Platfoot shared he is looking to purchase additional Schleuniger machines to help with company expansion. For small manufacturers considering equipment upgrades, he shared, “it will be crucial to continue to pursue automation to remain competitive.”

Schleuniger, Inc.

603-668-8117

Toll Free Technical Support: 877-902-1470