Adhesive Bonding

Satoshi Horikoshi, Ph.D. // Associate Professor of Materials and Life Sciences // Sophia University // Tokyo

Microwaves offer advantages over UV light and heat when curing epoxies.

Microwave Curing of Epoxy

The obvious disadvantage of UV curing is that the radiation must be able to reach all parts of the assembly. Photo courtesy Henkel Corp.

Adhesives that cure in a short time tend to be unstable during storage, while adhesives that are stable during storage tend to cure slowly. As a result, either heat or ultraviolet radiation is often used to hasten curing. However, both methods have some limitations. For example, some substrates might not be able to tolerate extended time in a curing oven. Similarly, the obvious disadvantage of UV curing is that the radiation must be able to reach all parts of the assembly.

Microwaves represent an alternative energy source for curing adhesives. Like UV radiation, microwaves consist of electromagnetic waves. Unlike UV radiation, however, microwaves are radio waves rather than light waves. As such, there are no components that microwaves cannot reach. And, since only materials that absorb microwave energy undergo self-heating, selective heating is possible. In fact, selective heating with microwaves makes it possible to cure an adhesive while simultaneously cooling other parts of the substrate by external means.

Several studies have examined microwave radiation as a potential heat source to cure epoxy adhesives. They have shown that the mechanical properties of adhesives cured with microwaves are similar to those of adhesives cured via conventional heating methods. Indeed, microwaves cured the adhesive faster than conventional heating methods, with an equivalent degree of conversion.

An added advantage of using microwaves is the possibility of incorporating an extraneous material into the adhesive that responds well to microwaves. For instance, carbon nanotubes (CNTs) and activated carbon powders react strongly with microwaves. In one study, CNTs were mixed with EPON 862 epoxy from Hexion Inc. to create a nanocomposite. Curing the mixture with 2.45-gigahertz (GHz) microwaves in a commercial microwave oven required only 10 minutes, compared with eight hours using a conventional oven.

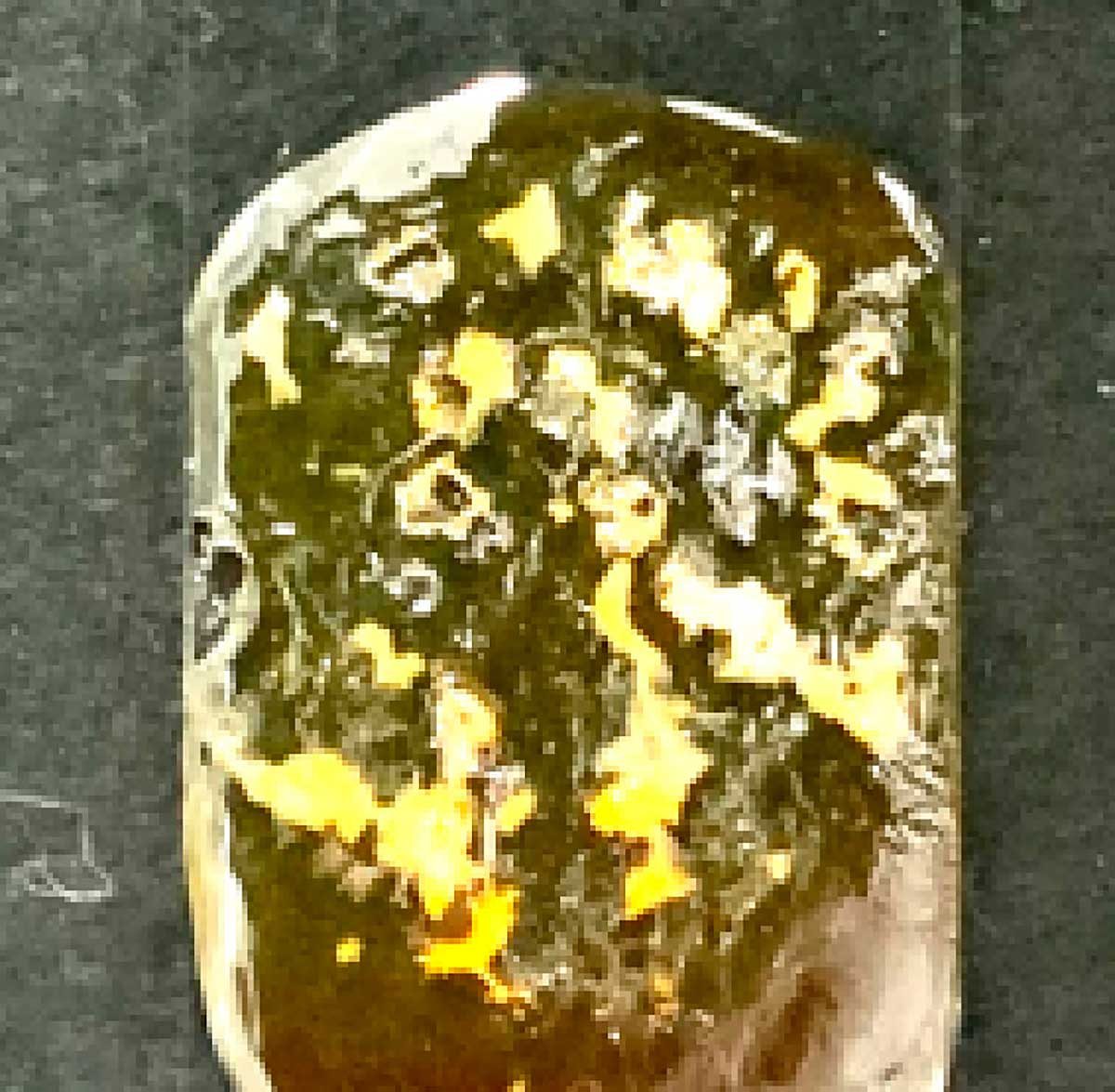

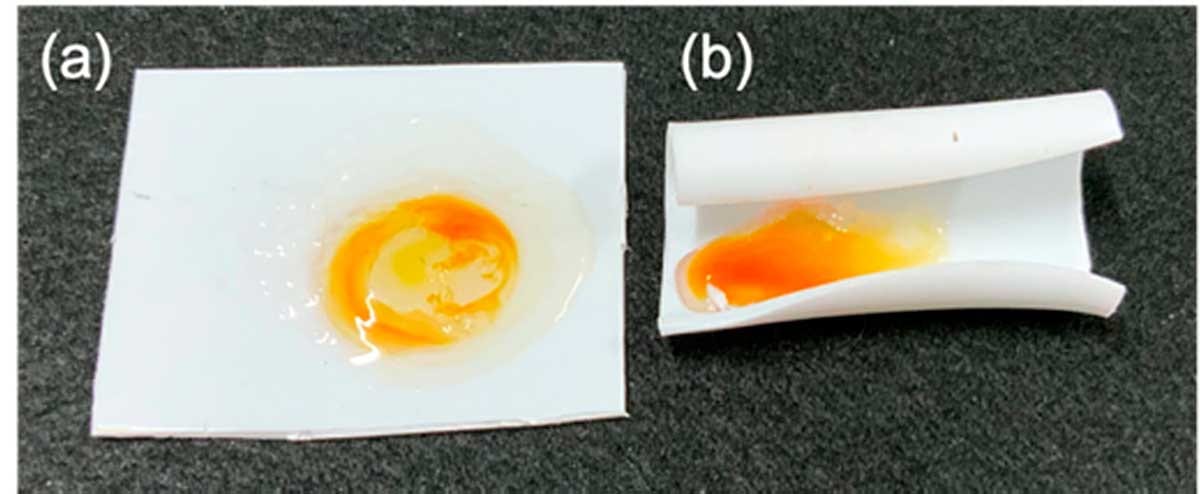

After 10 minutes of microwave heating, the epoxy cured to a clear resin (left). In contrast, after 20 minutes in an electric furnace, our epoxy still showed some uncured material (right). Photos courtesy Sophia University

It’s possible that microwaves could even make composites stronger. For example, one study found that drilling-induced delamination decreased, while mode I interlaminar fracture toughness increased by more than 66 percent in composites cured with microwaves compared with composites cured with conventional heating.

To date, most studies that have looked at microwave curing of epoxies have primarily been conducted with commercial microwave ovens and industrial multimode applicators. Control of microwave features is difficult at best with such devices, which precludes investigating details of the interaction between the microwaves and the substances involved in the curing process. In other words, although curing adhesives with microwaves is well-established, it is not possible to ascertain the principles of adhesive curing with microwaves.

We wanted to change that. Our goal was to examine the curing characteristics of an epoxy using 2.45-GHz microwaves. We used an apparatus that was capable of highly accurate microwave irradiation and precise temperature measurements during the curing process. The adhesive consisted of three components: the versatile, viscous epoxy resin bisphenol-A diglycidyl ether (BADGE), phthalic anhydride (PA) as the curing agent, and 2-ethyl-4-methylimidazole (EM) as the curing accelerator. Both the curing agent and curing accelerator are also versatile and storage-stable.

Our objectives were two-fold:

Elucidate the characteristics of curing with microwave heating and determine the raw material component that will be the driving force for microwave curing.

Demonstrate whether the problems associated with adhesives can be overcome by taking advantage of the characteristics of microwaves.

See us at The ASSEMBLY Show Booth 1613

Microwave Heating vs. Conventional Heating

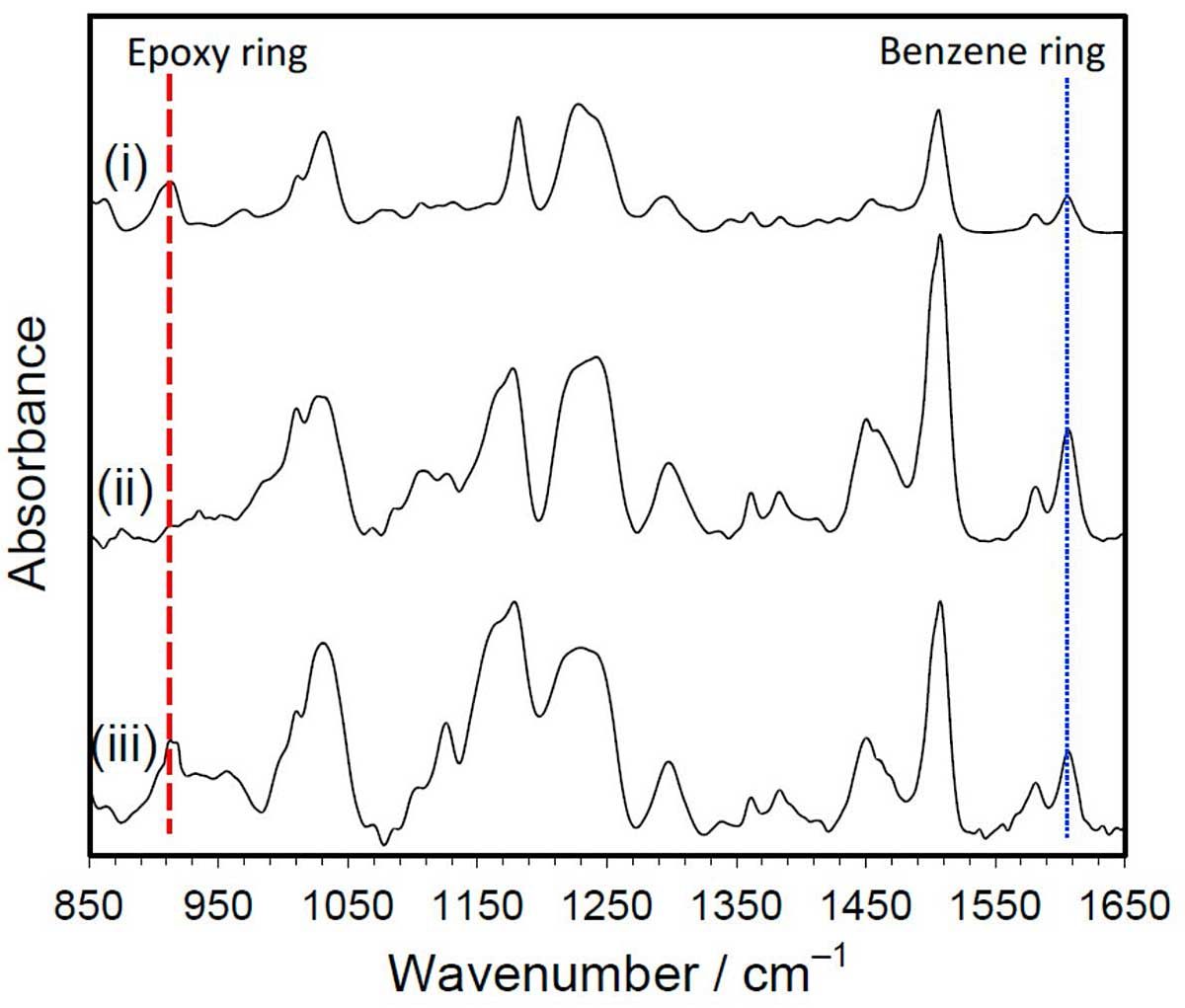

The quality of the cured adhesive was examined by attenuated total reflectance Fourier-transform infrared spectroscopy. Our tests indicated complete cross-linking of BADGE after 10 minutes of microwave heating. In contrast, complete cross-linking had not occurred after 20 minutes in the furnace. Source: Sophia University

Our first task was to compare how our adhesive cured with microwaves compared with an electric furnace.

When first mixed, our epoxy is a cloudy, viscous liquid. As it cures, the mixture becomes transparent so the degree of curing is easily observed visually.

After microwave heating for 10 minutes, the adhesive appeared as a pale-yellow transparent resin. In more detail, the PA began to become transparent about 5 seconds after the start of microwave irradiation. Approximately one fourth of the PA was not observable after 45 to 60 seconds of microwave irradiation. After 70 seconds, much of the PA disappeared, and after 80 seconds, the curing was complete.

The heating of the adhesive never occurred from the edge. In other words, heating appeared to proceed relatively evenly.

Curing in the furnace was different. After heating for 10 minutes in the furnace, the adhesive was sufficiently cured. However, visual observation clearly showed that unreacted PA was present near the center. Heating proceeded rapidly from the surface of the adhesive the moment the mixture was placed in the furnace. The edge of the adhesive appears to be more cured 30 seconds after being introduced into the furnace. After this time, however, no further changes were observed. After 180 seconds, the surface seems to have hardened. In reality, however, the resin was not cured and was soft when pressed with a finger.

See us at The ASSEMBLY Show Booth 643

In short, microwave heating ensured that the adhesive components reacted uniformly. In the furnace, curing was not uniform. The radiant heat from the furnace cured only the surface of the adhesive near the heat source, since the thermal conductivity of the adhesive is very low. Thermosetting did not occur much below the surface. In contrast, with microwave heating, the microwaves penetrated to the center to cause uniform thermosetting throughout. In addition, since the curing reaction is an exothermic process, curing was accelerated by self-heating.

The quality of the cured adhesive was examined by attenuated total reflectance Fourier-transform infrared spectroscopy. Our tests indicated complete cross-linking of BADGE after 10 minutes of microwave heating. In contrast, complete cross-linking had not occurred after 20 minutes in the furnace.

Prior to curing, the initial temperature of the sample was 25 C. With 20 watts of power, the sample needed just 32 seconds to reach a temperature of 140 C. In contrast, it took 81 seconds to reach 140 C with conventional heating.

The difference in the structure of the adhesive between microwave heating and conventional heating after curing was investigated by the attenuated total reflection technique using a diamond prism in the FTIR spectrophotometer. Differential scanning calorimetry was also performed. No differences were observed in the results.

Microwave Heating vs. Conventional Heating

These photographs illustrate the curing of the adhesive on a polystyrene plate by microwave heating (left) and heating in an electric furnace (right). The microwaves did not degrade the polystyrene. Photos courtesy Sophia University

The effect that microwave heating had on each component (BADGE, PA and EM) and on the mixture was examined by placing a sample in a quartz tube followed by heating with the microwaves’ E-field while observing the temperature changes. For each component, the temperature increase tended to be similar.

After 60 seconds of irradiation with microwaves, the temperature rise for EM began to decrease toward a plateau. At room temperature, naked EM is a clay-type solid that turns into a liquid at temperatures above 54 C. The decrease in the temperature rise near the melting point of EM suggests that the efficiency of microwave heating depends on the state of matter. In this regard, the microwave heating efficiency is governed by the dielectric properties of the materials.

Significant enhancement of temperature rise proceeded with initial irradiation with microwaves. Therefore, it seems that microwave heating promotes the chemical reaction between the curing agent and the plasticizer.

To further separate the factors that influence the heating rate, the mixture of PA and EM) was microwave-heated. That mixture displayed a higher microwave heating rate than did the mixture of BADGE, PA and EM. Moreover, the heating rate was more than three times better than that of either PA or EM alone.

A discussion on microwave curing of adhesives cannot be undertaken simply on the basis of the microwave heating efficiency of each raw material, since heating seems to vary greatly depending on the step of the curing reaction.

Although each component of the adhesive is a somewhat poor absorber of microwave energy, they nonetheless cause some microwave heating. The intermediates produced by the crosslinking reactions, however, do induce microwave heating. And, because of their charged nature, dielectric heating and Joule heating run parallel to generate heat.

Epoxies can be cured more quickly by heating the bonded assemblies in an oven. However, not all substrates can tolerate extended time in an oven. Photo courtesy International Thermal Systems

ASSEMBLY ONLINE

For more information on adhesive curing, visit www.assemblymag.com to read these articles: