The RC700E robot controller offers powerful motion control, open architecture, ease of use and safety. The controller powers the entire lineup of Epson’s high-power density GX-Series SCARA robots. The controller enhances productivity, enables collaborative robot applications, and reduces the footprint of robot automation systems.

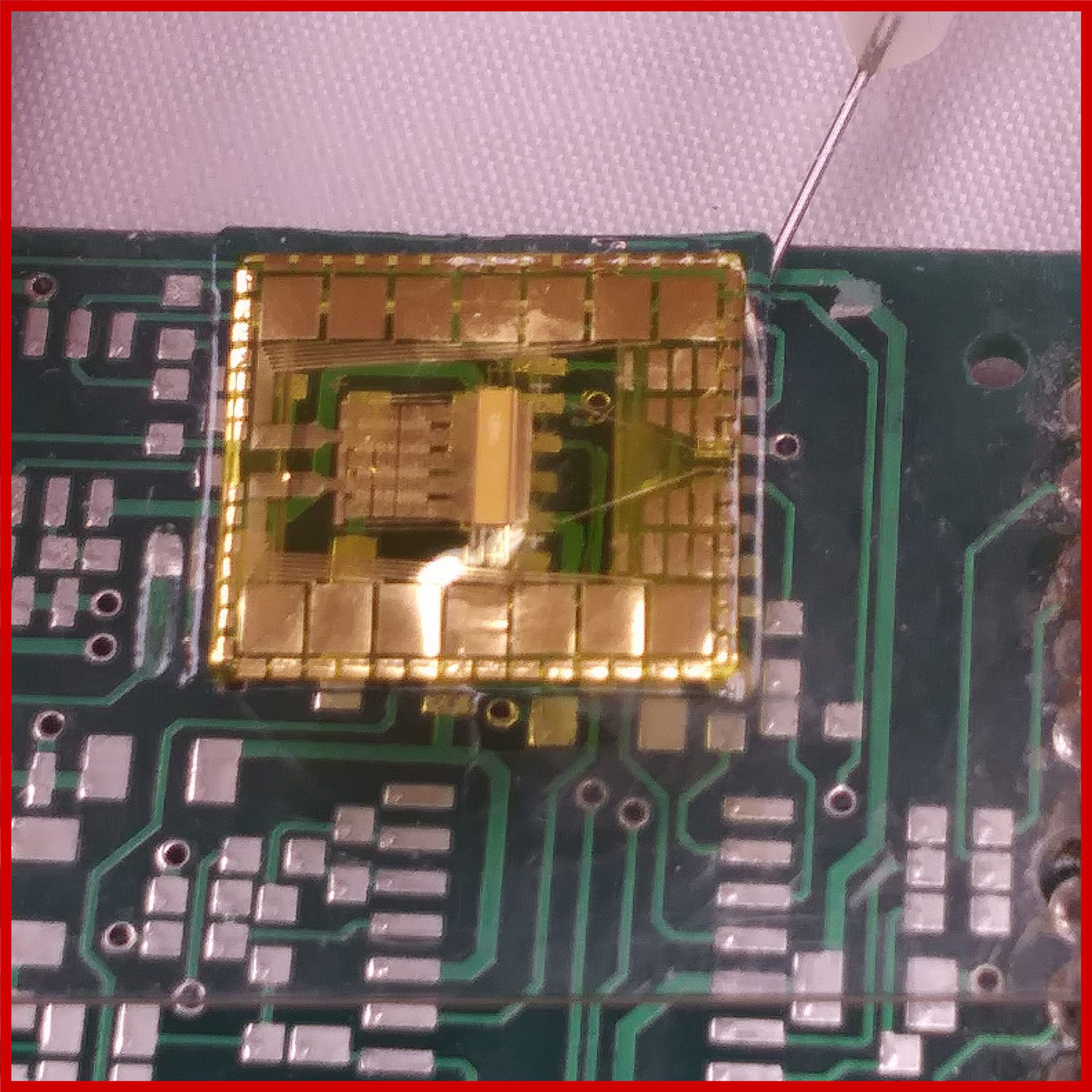

Featuring intelligent servo drives that provide high acceleration, smooth motion control and fast settling times, the controller enables engineers to integrate third-party software and hardware to create systems that suit their needs. More than just a connection to a PC, the RC700E integrates the power of PC-based controls and a real-time engine that can run up to 32 tasks with over 500 commands to optimize run-time, recovery and error handling.

Featuring integrated safety technology with an EN/ISO 10218 safety rating, the RC700E provides safe-rated speed and separation monitoring. With proper risk assessment, it allows interaction between workers and robots without a safety fence. This enhances productivity through faster interaction with machines for daily operations and maintenance. The potential elimination of physical safety barriers helps users reduce the footprint and overall cost of robot systems.

The controller includes Modbus TCP/IP, standard 24 inputs, 16 outputs and Epson RC+ software with no recurring license fee. RC+ software helps create powerful programs with a simple user interface, integrated debugger and 3D simulator. It also helps to create standalone robot applications that can be PC-based with API options, such as LabVIEW, or PLC-controlled with remote fieldbus options.

Three option slots are available for additional I/O, force guidance, conveyor tracking, fieldbus slave and analog I/O; seamless software integration with API (.NET), vision guidance and IntelliFlex parts feeding. Booth 1231

Learn More