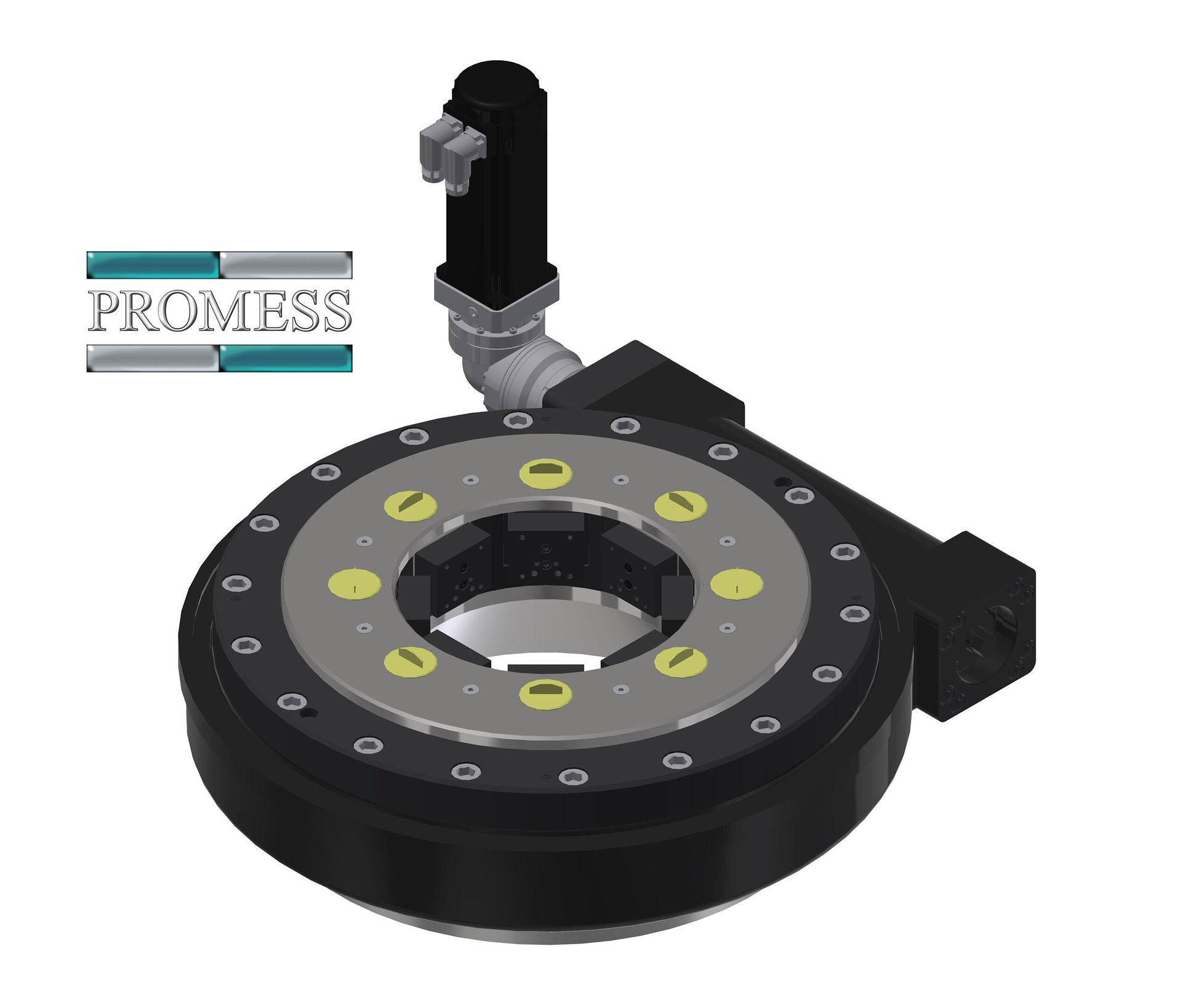

Press for Precise Radial Crimping

Incorporating sophisticated sensing and control technology, the Radial Press applies precise, even radial loads around the circumference of components or assemblies. The press is a fully programmable system using the UltraPRO controls platform. This platform allows for precise pressing commands, including moving to a specific force (minimum, maximum, average or combined), moving to a position, or moving to a rate of change.

Independent force feedback integrated into each internal actuator, along with high-accuracy encoder feedback, enables the product to handle a variety of radial crimping, joining and forming applications with precision. The software provides comprehensive graphs for each assembly, along with pass-fail indicators and full part history to monitor trends and facilitate adjustments. With a variety of configurations and force ranges, the press can be tailored to meet specific application requirements.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Promess Inc.

Work Cells With Riveter and Process Control

Standardized semiautomatic lean cells are equipped with a radial riveter, a process control system, and either a rotary indexing table or a belt transfer system. The former includes a safety enclosure; a rotary table 870 millimeters in diameter; and a riveter that can move 200 millimeters on the X axis and 300 millimeters on the Y axis. The latter has a custom belt-transfer system and workpiece holder instead of a rotary table.

These systems can double or triple throughput even with small to medium runs. Four riveting units are available, depending on the force required for the application. An optional proportional valve technique enables the cells to handle rivets of different sizes and materials in the same workpiece.

Both machines include process monitoring. Equipped with a USB interface and a 5.7-inch, backlit, LED touch-screen, the controller can store 63 riveting programs. Engineers can program six control parameters and 45 riveting modes.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

BalTec Corp.

Pneumatic Press With Monitoring

Pneumatic presses with force and stroke monitoring can be ordered as complete systems with Schmidt’s Press Control 700. These systems are characterized by sensors and signal amplification integrated in the press head. These signals are evaluated in real time. Direct forces are measured, since the force sensor is integrated in the ram. As a result, the measurement is not affected by side forces, and signal readings are not affected by outside interference.

The non-rotating rectangular ram is equipped with fully adjustable, Teflon-lined gibs for precise travel. No die set is required. Maximum force ranges from 320 to 9,650 pounds. Throat depth ranges from 5.16 to 6.3 inches. Working height ranges from 5.51 to 23.62 inches.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

SCHMIDT Technology

HMI for Assembly Presses

The Tox Universal Data Interface (UDI) is a panel PC for assembly press systems. It includes a touch-screen interface, Tox software and a Linux operating system for maximum IT security. Available in 10-, 13- and 21-inch designs, it provides control and visualization of a pressing system, as well as storage and processing power of data in real time. The UDI is compatible with many database collection systems, such as MQTT and OPC UA. It has a solid-state drive with 250 gigabytes of memory for storing assembly data. It carries an IP66 protection rating against dust and water.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Tox-Pressotechnik