A special section to ASSEMBLY

Electromechanical Crimping Tool

The EMC3300 is a lightweight, ergonomic electromechanical tool for crimping stamped and formed contacts, terminals and splices onto copper and aluminum cable 26 to 10 AWG. It has a one-trigger design and pre-clamp function to make crimping simple and quick. Interchangeable die sets allow the tool to produce hex, confined crescent, and nest-and-indent crimp styles. The tool also accommodates some die sets supplied by connector sources.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Daniels Manufacturing Corp.

Fully Automatic Stripping, Crimping

The Zeta 620 is the smallest model in the Komax Zeta series of automated sequential wire assembly machines. With a footprint of just 2,150 by 1,545 millimeters, it can produce 360 cables per hour, complete with ferrules on both ends. The machine can handle up to 24 different cables without the need for changeover. The machine can accommodate seven different ferrules and wire cross-sections ranging from 0.5 to 6 square millimeters.

This machine can automatically produce the entire list of cables for a control cabinet. The cables come out ready to install, with labeled ends that make it clear which components they are connected to.

Data2Wire software uses digital files instead of paper schematics to communicate assembly requirements to the machine. The software integrates with 3D CAD systems, enabling the seamless conversion of digital designs into production data. For companies not yet using 3D CAD, Komax offers Digital Lean Wiring software, which can prepare wire assembly data from simple wire lists or 2D drawings. This ensures that wires are produced in the correct sequence and pre-labeled.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Komax Corp.

Electromechanical Crimping Tool

The CPM-100HG5 prints and cuts vinyl signs and labels. This thermal printer produces labels in full color. Applications includes labels for wires and cables; ANSI and OSHA signage; health and safety signs; product and asset labeling; visual management signs; pipe marking; and 5S, kaizen and kanban labels.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

MAX USA Corp.

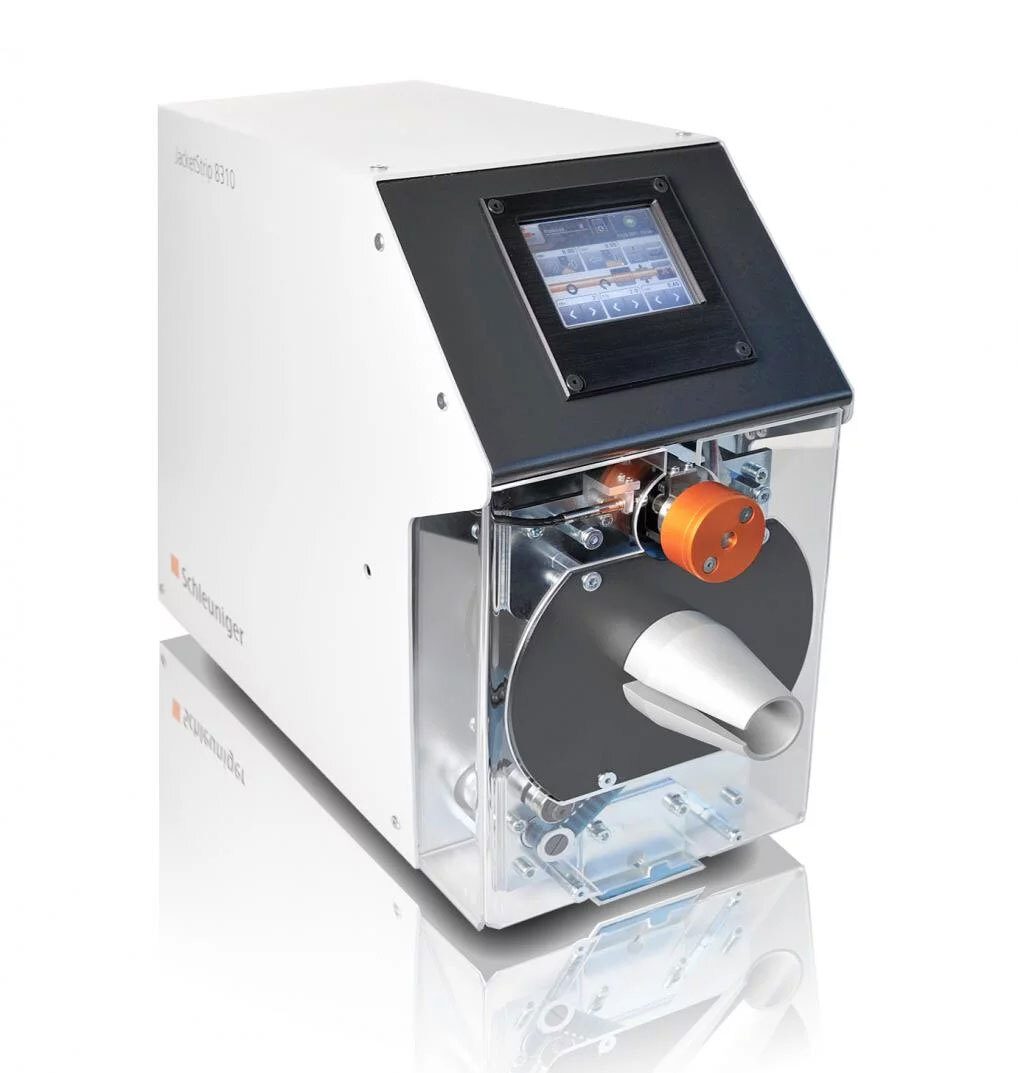

Machine Slits Outer Jacket of Insulated Cables

The JacketStrip 8310 precisely slits the outer jacket of insulated cables. Due to the unique floating blade system, round or out-of-round cable jackets can be processed without damaging the cable layers beneath. Radial and axial slits can be performed to facilitate jacket removal in a secondary manual operation. Simple operation, short cycle times and a universal blade design provide a good return on investment.

A rotating blade, which precisely follows the surface of the jacket, ensures precise radial slitting of the jacket. Optionally, the cable jacket can be slit lengthwise while extracting it from the machine. After the slits have been made, the insulation jacket can easily be removed by hand. The machine can process cables from 0.1 to 1 inch OD and up to 19.7 inches in stripping length without any damage to the inner conductors or shielding. No blade changes are required. Programming is done via a color touch-screen. A digital display shows axial and radial blade depths.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Schleuniger Inc.