ASSEMBLY ESSENTIALS

How to Determine When Electric Riveting/Forming Technology is a Better Option than Traditional Pneumatic/Hydraulic Technology

For over 50 years, BalTec has been a leader in joint forming technology such as radial, orbital and roll forming. BalTec has a worldwide presence through a diverse sales and support staff with offices and plants located in Switzerland (headquarters), United States, Germany, France, Great Britain, Brazil, China, Spain and Mexico.

Traditionally, joint forming technology was accomplished through pneumatic or hydraulic pressing. Adding rotary tool motion to the press operation greatly reduces the amount of downward force needed to accomplish the same or better results. An ongoing industry demand in the manufacturing and assembly process is to increase production and decrease costs while maintaining or improving quality. Through BalTec’s continuous improvement, advancements were made with the BalTec HPP Process Controller to effectively monitor, control and adjust the riveting process through industry-proven projection control and Auto-Compensation modules that allow high deviations in part tolerances.

Limitations still exist with effectively controlling a pneumatic/hydraulic cylinder, not to mention the high operating costs and environmental impact associated with the traditional process. One may use a slower approach speed or add-on device to achieve a high level of control, but this leads to longer cycle times, lower production and greater potential of downtime due to component failure. In the past, it has been expensive, difficult or impossible to obtain precision and speed when using traditional pneumatics or hydraulics.

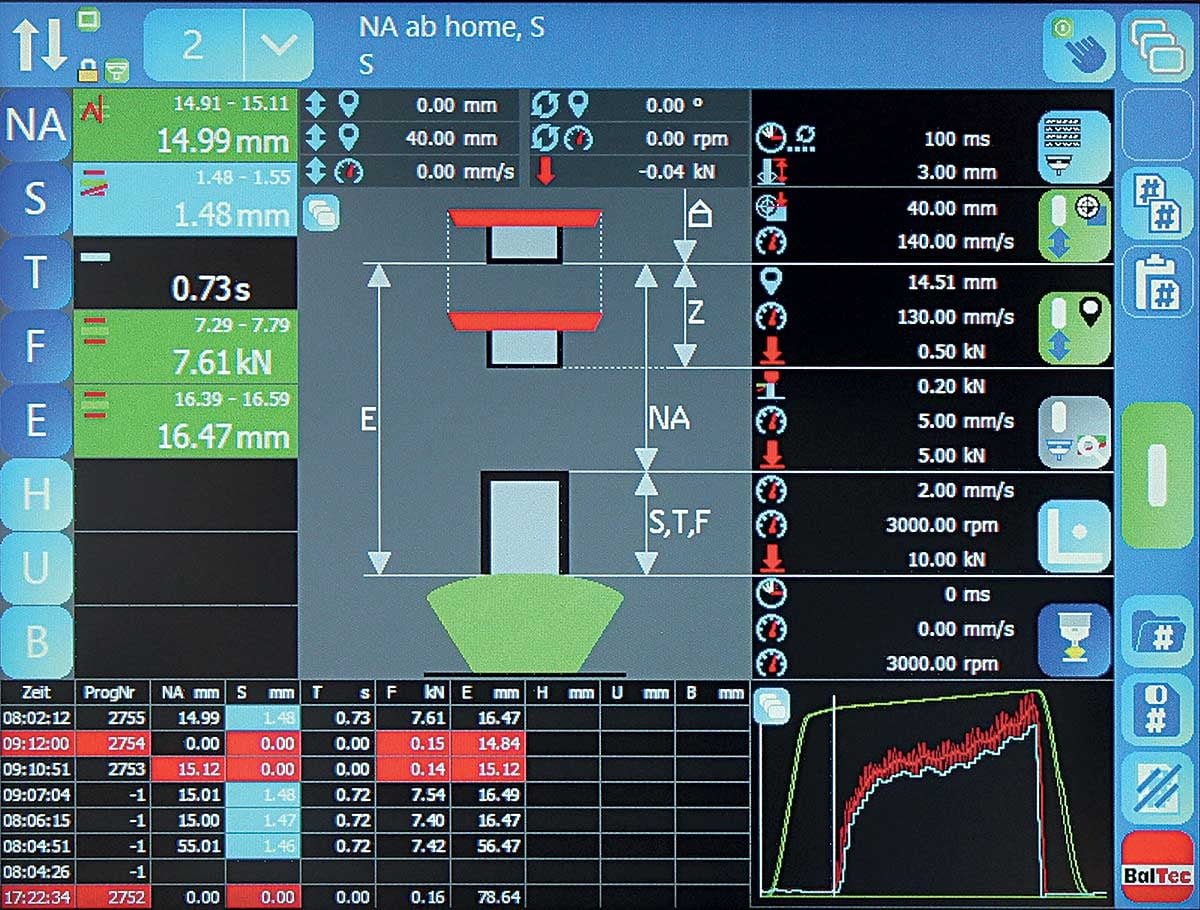

A line of BalTec Electric Riveting unit addresses these issues associated with traditional pneumatic/hydraulic riveting machine by using a 100% electrically powered unit. You now have full positional control due to servo-driven rotary and linear motion allowing for real-time monitoring and process control of linear force, speed and position. Another advantage is process data collection and remote access to data, parameters and programs making it Industry 4.0 ready. Associated operating costs of a pneumatic/hydraulic unit has now been eliminated as well as a making the BalTec Electric unit an environment friendly device since air-oil and hydraulic fluid is non-existent. Due to the drive screw and bearing design, the Electric unit has a greater power density than pneumatic where space may be a premium in automation work cell design.

The traditional pneumatic riveting machine may suffice on some joint forming applications, but if your specific application demands a very short cycle time, or high level of control while maximizing throughput and assuring quality, or if traditional joint technology does not meet your requirements, then the BalTec Electric Riveting unit may be the right choice. With our vast knowledge and experience in joint forming technology, contact a local office to assist in determining if the BalTec Electric Riveter is the right option.