ADHESIVE BONDING

Francesca Cavezza, Ph.D.// Development Chemist // Arteco NV // Brussels, Belgium

Surface preparation of aluminum plays an important role in the durability of bonded joints.

Bonding Aluminum in Automotive Assembly

During the past decade, the average amount of aluminum in passenger cars has doubled. Based on the latest designs, this trend will continue in the coming years.

However, switching from steel to aluminum is not straightforward. For example, aluminum is 50 percent lighter than steel, but it has an average elastic modulus of 70 gigapascals, while that for steel is 207 gigapascals. As a result, aluminum parts are typically 40 percent thicker than their steel counterparts.

Aluminum alloys are not easily spot-welded. They have low electrical resistance, a stable and nonconductive oxide layer, and a tendency to interact with the electrodes. In addition, the heat from the welding process can weaken the parts, particularly their fatigue strength.

In lieu of welding, automakers are increasingly using structural adhesives for assembly, either alone or in combination with mechanical fasteners. For example, the body-in-white of the Mercedes S-Class coupe has more than 100 meters of structural bonds, and the BMW 7 series contains more than 10 kilograms of structural adhesive.

Besides structural applications, automakers are using adhesives in other body-in-white applications. “Anti-flutter” adhesives reduce vibration between outer and inner body panels. Such adhesives are commonly used on horizontal panels, such as the hood, trunk lid and roof. Adhesives are also used to join and seal the hem flange areas on doors, hoods and tailgates.

Advantages and Limitations

Adhesives offer significant advantages over other joining techniques. Adhesive bonding does not interfere with the aluminum metallurgy or create thermally or mechanically weakened zones. Stress is distributed uniformly over the whole bonded area, which increases the static and dynamic stiffness of the vehicle structure. Since the body structure is more rigid, the resonant frequency modes will be higher and the structural damping faster. As a result, the vehicle will have better noise, vibration, and harshness characteristics. When used in combination with other joining techniques, adhesives improve crash performance and fatigue strength. Adhesives also enable the joining of dissimilar materials, and by isolating different metals, they protect against galvanic corrosion.

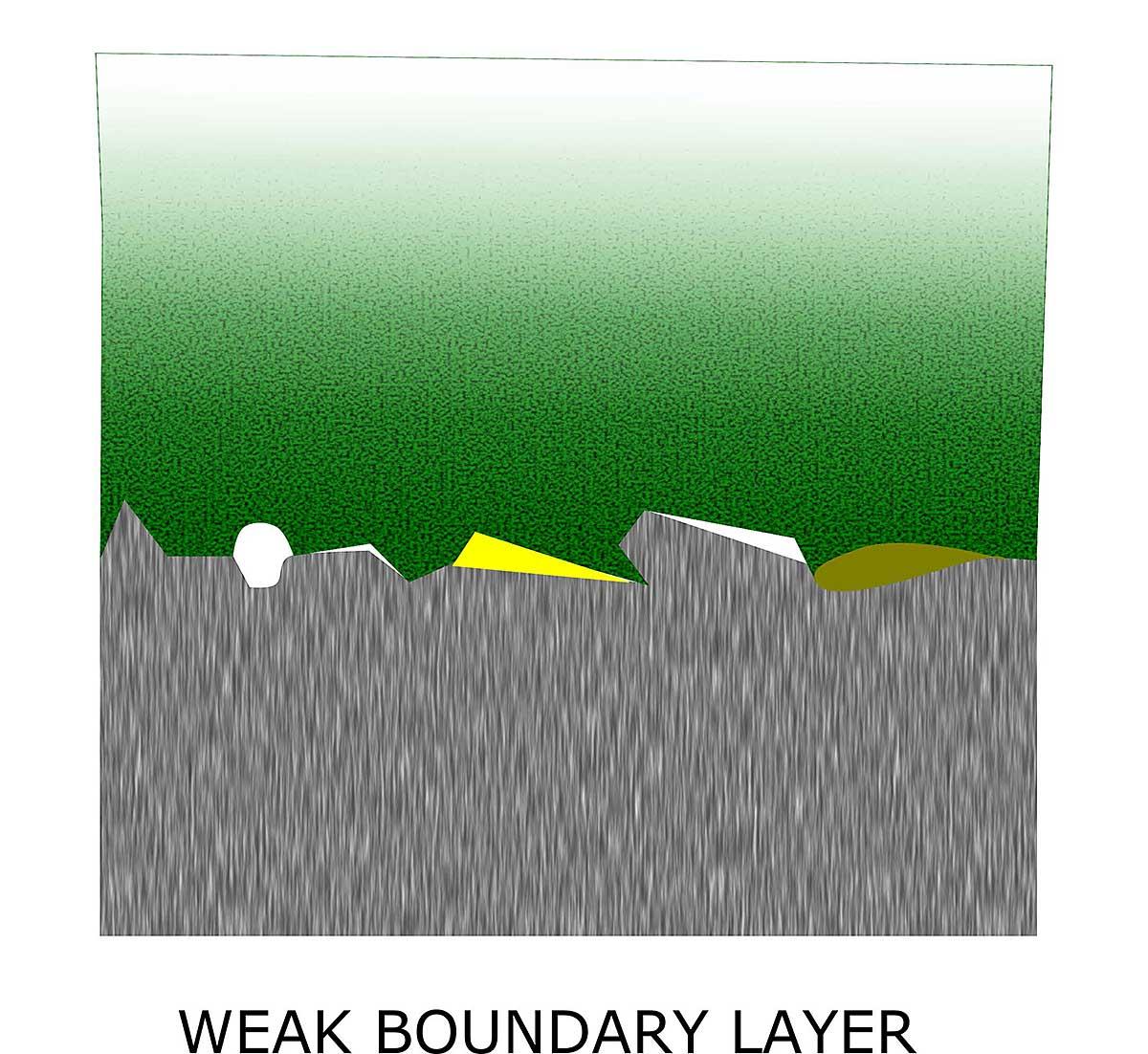

Removing the weak boundary layer is particularly important to a good bond. This layer is formed at the interfacial region of an adhesive joint, causing the joint to fail at lower stresses than expected. It includes oxides and contaminants, such as lubricants, from various manufacturing processes.

Illustration courtesy Free University of Brussels

Aesthetics are another advantage of adhesive bonding. There are no visible weld seams or rivet heads, so adhesive bonding can minimize or eliminate secondary operations such as grinding and polishing. Yet another benefit is gap filling. Adhesives can bridge large gaps between panels and improve the overall appearance of the assembly. In many cases, joining and sealing operations can be combined.

Adhesive bonding entails some disadvantages, too. Among the most significant is the durability of adhesive joints when exposed to harsh environmental conditions. Another issue is that the substrates may need to be pretreated to achieve strong, durable bonds, especially with aluminum alloys. As with welded joints, bonded structures cannot be easily dismantled for repairs. And, in many cases, the joint may need to be supported until the adhesive has cured, which can slow down production. This is one reason why structural adhesives are typically used in combination with another joining methods, such as riveting.

Surface Contaminants

Adhesives can be used on aluminum sheets, extrusions and castings. Regardless of the form, the aluminum surface must be treated to:

Remove weak boundary layer formed by heat treatment or exposure to humidity, airborne contamination, oil and grease.

Enhance molecular contact between the adhesive and the substrate to promote the formation of intrinsic adhesion.

Create a continuous film on the oxide layer that is stable over a wide pH range, protects against hydration, and creates a barrier against corrosion.

Removing the weak boundary layer is particularly important. This layer is formed at the interfacial region of an adhesive joint, causing the joint to fail at lower stresses than expected. This layer includes oxides and contaminants, such as lubricants, from various manufacturing processes. Surface preparation will most likely not remove this contamination completely, but it will produce a surface that will be less affected by cohesive weakness.

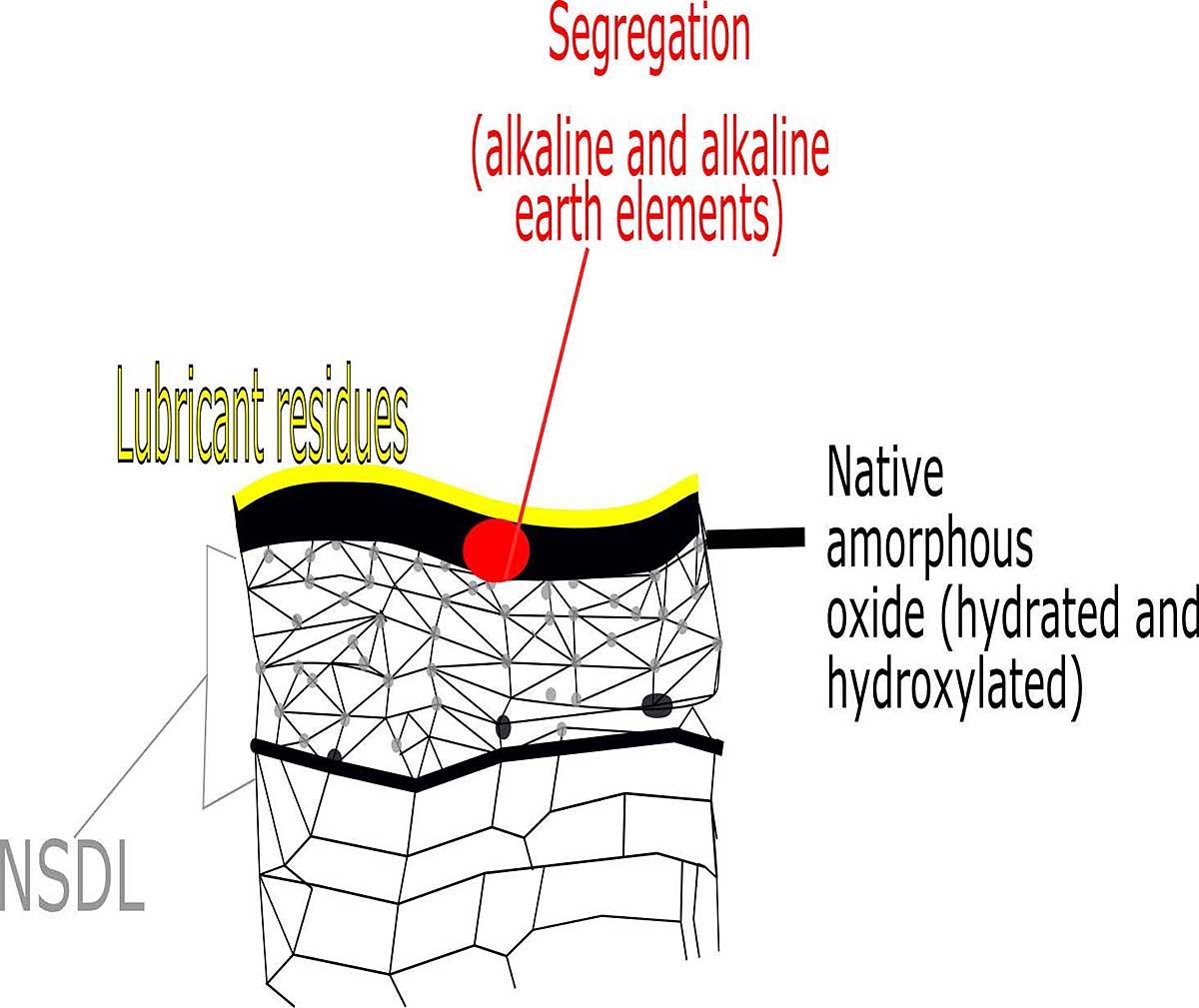

One characteristic of aluminum after rolling is the so-called near-surface deformed layer (NSDL). When the roller is biting the surface of the metal, it can initiate cracks in the oxide layer. As the sheet exits the roller, mill metal or intermetallics can stick to the roller’s surface. In successive rolling cycles, these particles get redeposited on the surface of the sheet and create even more imperfections or cracks in the oxide layer.

Illustration courtesy Free University of Brussels

To produce aluminum sheets, aluminum undergoes a rolling process, either hot or cold. Lubricants are applied to keep the rollers and the workpiece separated. This minimizes friction and reduces the risk of damage to the surface of the sheet. The lubricants are typically paraffin-based and are volatilized during annealing or by natural evaporation. However, the rolled surface can still have a certain degree of contamination, which must be removed via degreasing.

Aluminum is very reactive and has a high affinity for oxygen. When it is exposed to air, a thin layer of oxides will instantaneously form on the surface.

If the oxide layer forms at a temperature below 375 C, it will consist of a thin, amorphous layer of Al2O3, 1 to 2 nanometers thick, covered by hydrated surface oxides and hydroxides. All totaled, the oxide layer can be 2 and 60 nanometers thick. Oxidation and hydration can be accelerated by the presence of alkaline and alkaline earth elements, such as lithium, sodium and magnesium, segregated at the surface or at the metal-metal oxide interface. Magnesium, in particular, can migrate to the surface during heat treatment. Aluminum hydroxides are actually good for interaction with the acid polar sites of polymers. However, hydration may reduce overall adhesion performance, since it creates weaker basic sites on the top surface.

If the oxide layer forms at a temperature above 400 C, the amorphous oxide may crack due to thermal expansion and crystalline Al2O3 can be formed. This can have a detrimental effect on total adhesion. The presence of magnesium also promotes crystalline oxide growth.

Cleaning and Pretreatment

Another characteristic of aluminum after rolling is the so-called near-surface deformed layer (NSDL). When the roller is biting the surface of the metal, it can initiate cracks in the oxide layer. As the sheet exits the roller, mill metal or intermetallics can stick to the roller’s surface. In successive rolling cycles, these particles get redeposited on the surface of the sheet and create even more imperfections or cracks in the oxide layer. This process creates a layer on the surface of the aluminum that is different from the underlying metal. This layer is the NSDL.

The thickness of the NSDL varies between 1.5 to 8 microns, depending on the rolling mill. An NSDL can form during both hot and cold rolling. There is a strong correlation between the presence of an NSDL and the susceptibility to filiform corrosion for 3xxx and 5xxx aluminum alloys.

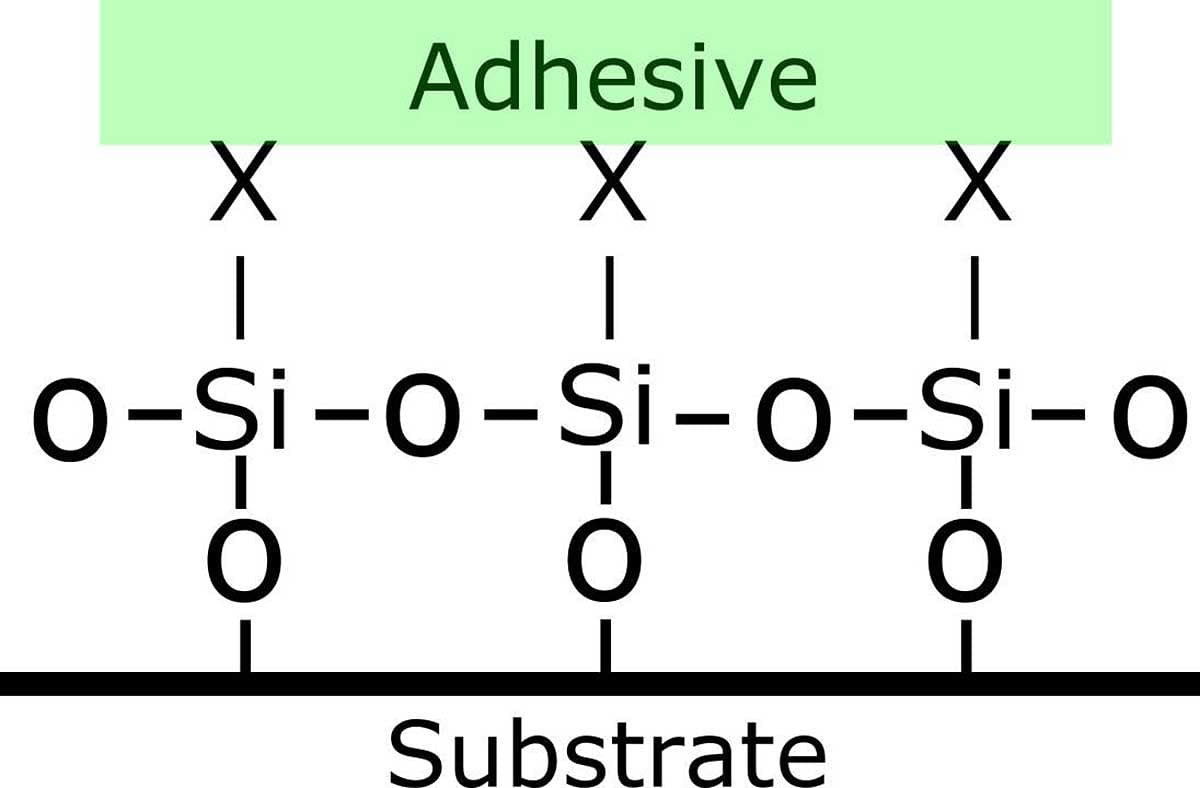

The role of coupling agents is to improve the degree of cross-linking in the interface region to increase chemical bonding. Silanes, the most common coupling agent, can form chemical bonds with both the substrate and the adhesive.

Illustration courtesy Free University of Brussels

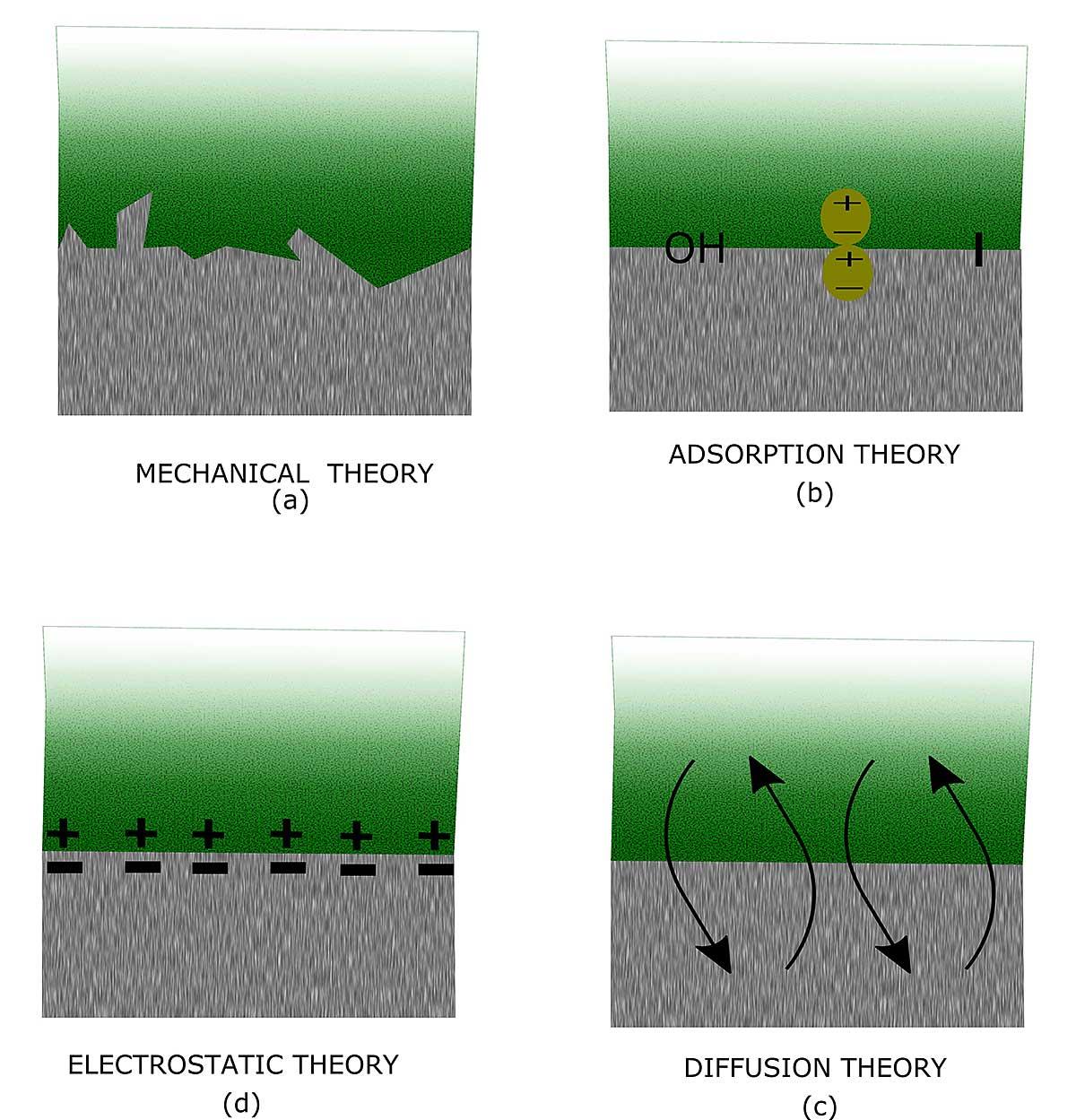

There are several theories about why adhesive adheres to aluminum. These include mechanical (a), adsorption (b), electrostatic (d) and diffusion (c).

Illustration courtesy Free University of Brussels

Before pretreatment, the aluminum substrate should be cleaned of residual oil, dirt and surface oxides. For 5xxx alloys, the main requirement for cleaning, besides removing organic residues, is to ensure the removal of magnesium-rich oxides, which can have a detrimental effect on the adhesion of coatings.

The most used cleaning method for aluminum sheets in the auto industry is a mixed-acid process. The aluminum is bathed in a mixture of sulfuric, phosphoric and hydrofluoric acids at a temperature of 50 to 70 C. This removes the NSDL and makes the metal more resistant to corrosion.

After cleaning, the aluminum is given a pretreatment to modify the surface chemistry, improve adhesion and boost corrosion resistance. There three types of pretreatment:

Metal ions and inorganic molecules, which react with, or precipitate on, the oxidized aluminum to form a mixed oxide layer.

Coupling agents, which promote adhesion.

Anodization, which modifies the aluminum oxide.

In the automotive industry, the most widely used metal ion treatments are conversion coatings based on titanium fluoride or a mixture of titanium fluoride and zirconium fluoride. The treatments can be applied with immersion, spray or no-rinse processes. The advantage of these coatings is their speed and simplicity. They can dry in place, and they can be applied at low temperatures.

To obtain even better adhesion and to attain a homogeneous coating, organic additives can be added to the conversion baths. These additives include polyacrylic acid, phenol phosphate, silanes and chelating agents, such as amino trimethylene phosphonic acid.

Among coupling agents, silanes are used the most. The role of coupling agents is to improve the degree of cross-linking in the interface region to increase chemical bonding. Silanes can form chemical bonds with both the substrate and the adhesive. The advantage of silanes is that they are simple and stable, due to their covalent cross-linked structure. They also improve surface wettability. The one drawback of silanes is their relatively short shelf-life.

Organophosphonic acid-based coatings are also used as coupling agents. Organophosphonic acids form very stable monolayers on aluminum alloys covered with a thin oxide film. The presence of phosphonate monolayers enhances adhesion with aluminum oxide. These acids can be applied via dip coating or spraying.

Another pretreatment is anodization. Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. And, the porous surface provides adhesion to adhesives and primers. Anodizing is accomplished by immersing the aluminum in an acid electrolyte bath and passing an electric current through the medium.

The advantage of anodization is that it creates a pure aluminum oxide surface. It’s more environmentally friendly than other pretreatments, and the thickness and morphology of the finished oxide can be easily controlled. On the other hand, it’s also more expensive and difficult to apply in high-volume production.

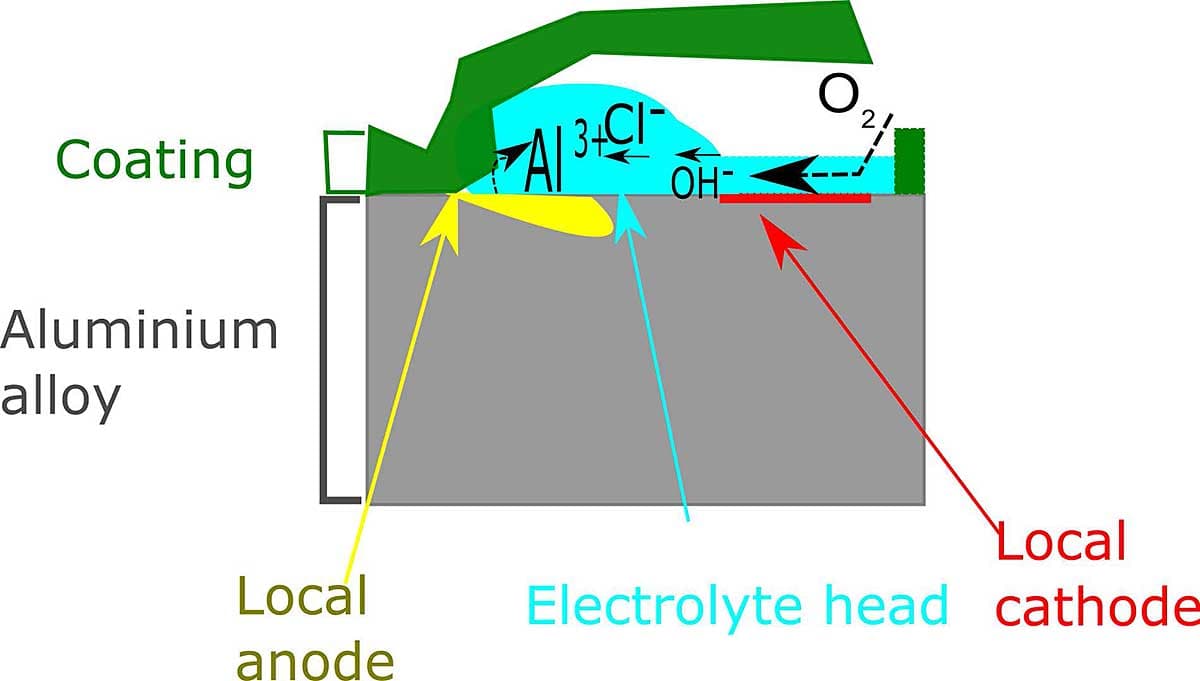

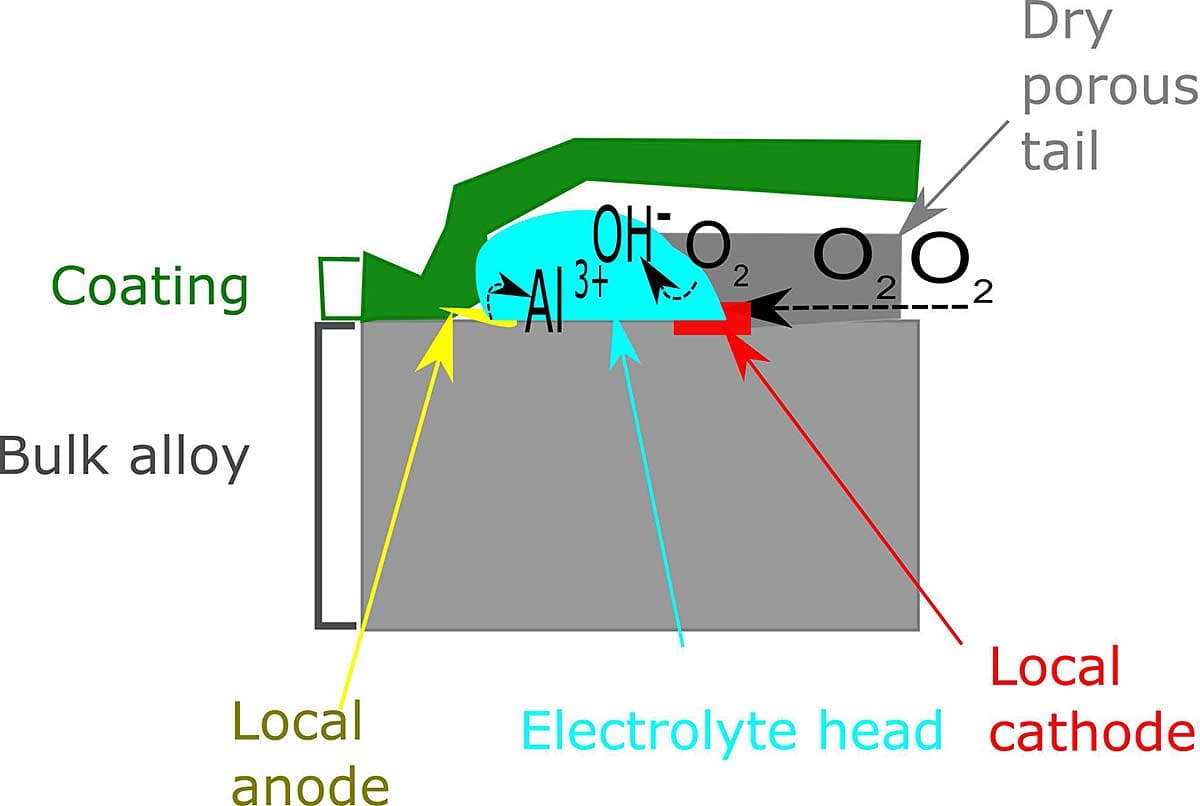

Filiform corrosion is a form of atmospheric corrosion that occurs under organic coatings in the form of narrow interconnected thread-like filaments. This diagram shows the process of initiation (a) and propagation (b) of filiform corrosion on aluminum.

Illustration courtesy Free University of Brussels

Mercedes employs anodization on its CLS class sedan. It’s also used on the Lotus Elite and Opel Speedster sports cars.

After pretreatment, a stamping lubricant is usually applied to the metal to improve formability and to protect the substrate prior to bonding. The amount of oil applied is approximately 0.9 gram per square meter. However, if the oil is not a dry-film lubricant, there will be a nonhomogeneous distribution on the surface due to run-off.

These lubricants are not necessarily removed at the stamping plants, so it’s important for the adhesive to be compatible with them. The adhesive must be able to either displace or absorb any lubricant if it is to form a strong bond. For example, certain epoxies can displace and absorb oil.

Several studies have shown that stamping lubricants can adversely affect joint strength. For example, one study showed that joint strength decreased as the amount of lubricant increased when bonding 6111 aluminum alloy to high-strength-steel. Another study found that 2.21 grams per square meter of hydrophobic lubricant was enough to adversely affect bond strength.

The average amount of aluminum in passenger cars has doubled during the past decade. Photo courtesy Jaguar Land Rover

Environmental Degradation

One of the main drawbacks of adhesive joints is their long term durability when exposed to environmental conditions.

Water can enter a bonded joint by bulk diffusion through the adhesive, interfacial diffusion along the interface between the adhesive and substrate, and by capillary action through cracks or defects in the adhesive or conversion layer. It can adversely affect the system by either modifying the adhesion properties or by displacing the adhesive at the interface.

Once water reaches the joint, there are several ways in which it can affect the adhesive. These include:

causing plasticization.

causing the adhesive to crack, craze or hydrolize.

attacking the adhesive-adherent interface.

causing stress due to swelling.

In some cases, this damage is reversible when the joint dries. In other cases, the damage is irreversible.

This is why pretreatment is so important. Creating primary bonds between the adhesive and the substrate greatly improves the strength the joint.

Humidity can be just as detrimental to adhesive bonds as water. For example, one study exposed aluminum joints bonded with various structural adhesives to 100 percent relative humidity at a temperature of 50 C. The researchers found that joint strength decreased significantly, but it would partially recover when humidity was decreased.

Corrosion protection depends on the adhesion of the coating layer to the substrate. When the bond between the coating and the substrate is strong, water cannot penetrate to the interface and corrosion does not develop fast. However, when the bond is weak, the corrosion can easily propagate at the interface.

One study looked at the effect of long-term salt spray on the strength of lap-shear aluminum joints bonded with hem-flange sealant. One set of joints was treated with a zirconium-titanium coating; another was bare aluminum. The study found that initially, the zirconium-titanium coating provided better corrosion protection than bare aluminum. However, in the long term—more than 1,400 hours—the coating provided worse protection than the bare metal.

Filiform corrosion is a form of atmospheric corrosion that occurs under organic coatings in the form of narrow interconnected thread-like filaments. It was observed for the first time in the late 1960’s where it occurred around rivet heads and the edges of the aluminum skins on aircraft exposed to aggressive tropical environments.

In the case of polymer layers on nonconductive oxide surfaces, as on aluminum alloys, filiform corrosion is due to anodic delamination. The loss of adhesion is caused by the anodic dissolution of the substrate. The main environmental factors that are crucial for the initiation and proliferation of this form of corrosion are relative humidity above 80 percent, the presence of aggressive ions such as chorine, and defects in the protective coatings.

Automakers are increasingly using structural adhesives to assemble aluminum parts, either alone or in combination with mechanical fasteners.

Photo courtesy ThyssenKrupp AG

Stresses and Durability

main advantages of adhesive bonding is that it distributes stress over a large area. However, that does not mean engineers can ignore the issue of stress. Applying a stress will cause an adhesive bond to degrade at a faster rate than an unstressed bond, especially if the bonds are subject to high loads for prolonged periods.

Bonded joints can be exposed to both static and dynamic stresses. These stresses are not only due to external loads. They can originate from adhesive shrinkage after curing, adhesive swelling due to water adsorption, or from a thermal mismatch between the adhesive and the substrate. Moreover, stress can also accelerate other processes, such as the rate of diffusion of moisture in the joint.

Stress-durability testing is recommended to verify the performance of the joint design and adhesive selection. For example, one study looked at the effect of environmental exposure on the fatigue strength of mild steel joints bonded with various adhesives. Double lap shear joints were kept under different loading and environmental conditions for eight years. The researchers found that the adhesive used had a major impact. Some formulations showed excellent durability, while others were adversely affected by the environment. The adhesives that showed better performance were the ones cured with polyamide hardeners and those with high initial strength and Young’s modulus.

Editor’s note: The following people also contributed to this article: Matthieu Boehm, research scientist, Constellium Technology Center, Voreppe, France; Herman Terryn, Ph.D., professor of surface science and engineering, Free University of Brussels; and Tom Hauffman, Ph.D., associate professor of chemistry, Free University of Brussels.

This article is a summary of a much longer research paper. To read the complete paper, click here: https://bit.ly/36hNpRv.

ASSEMBLY ONLINE

For more information on product or adhesive bonding, visit www.assemblymag.com to read these articles:

Adhesive Bonding System Improves Sunroof Assembly at Mercedes-Benz

Composite Joining: Adhesive Pros and Cons

Adhesive Assembles Composite Parts for New Motorhome

Scroll to

read full story