FEATURES

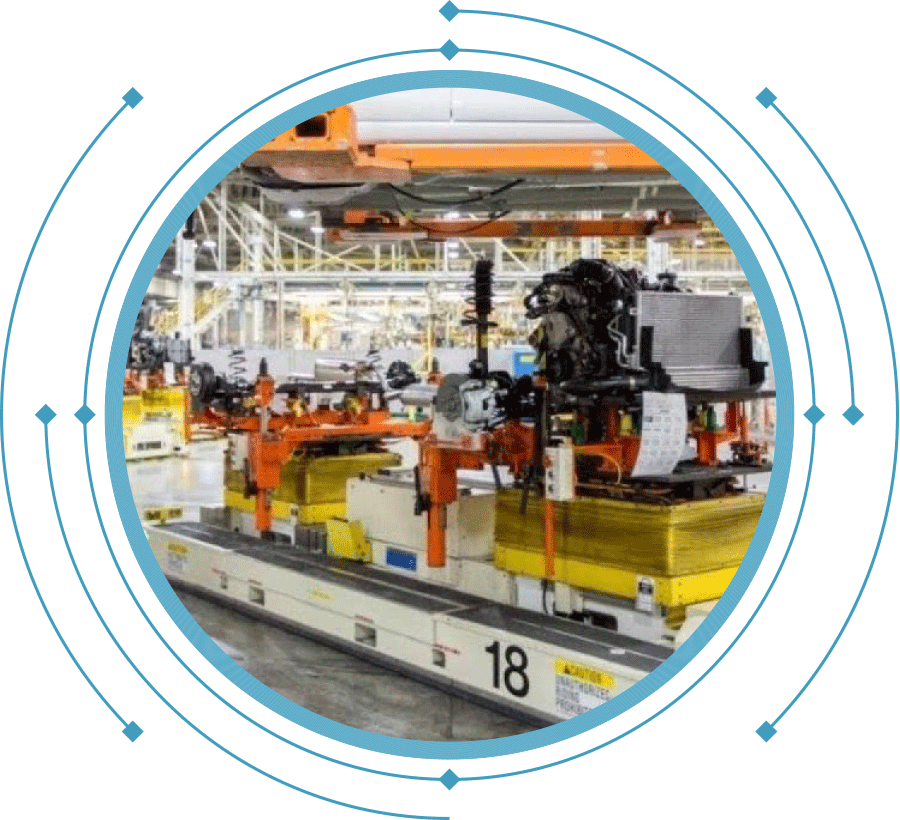

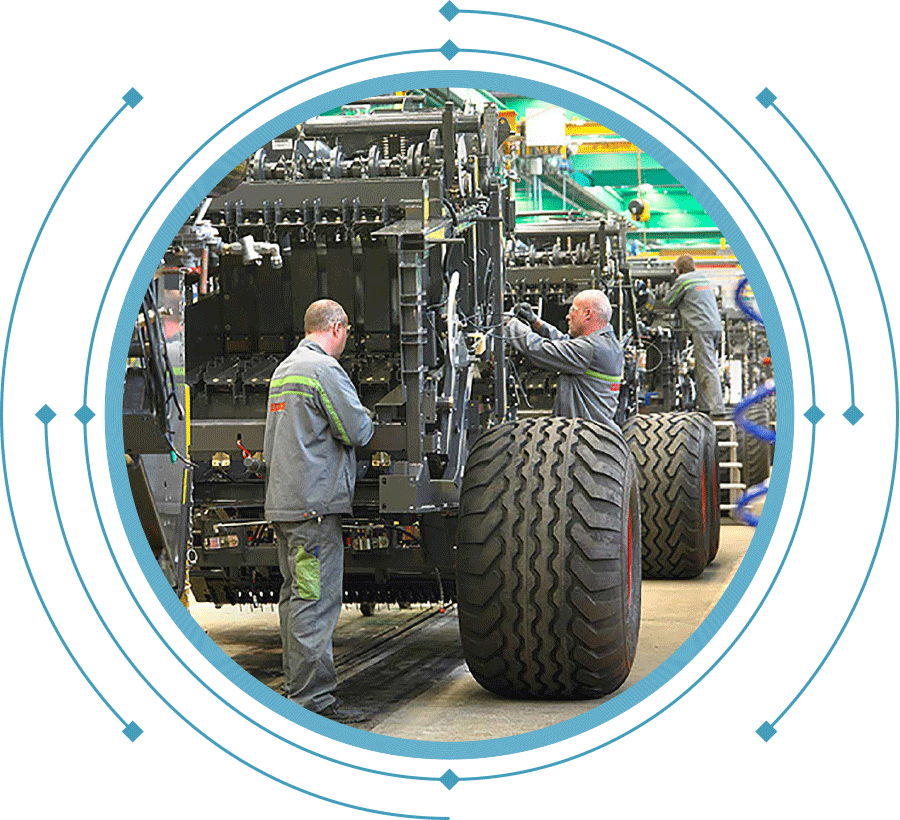

At SEAT’s automotive plant in Martorell, Spain, autonomous mobile robots deliver parts to the line. They don’t follow a track. They’re simply given a load and told where to go. Twenty-three miles away, engineers at Nissan’s assembly plant in Barcelona use additive manufacturing to produce 100 jigs and fixtures each year. At Merit Medical Systems’ factory in West Jordan, UT, the entire manufacturing process, from molding to packaging, is accomplished with almost no manual labor. This eBook details the leading-edge technologies of Industry 4.0.

Smart Factories: Here and Now

Highly automated smart factories are no longer a pie in the sky concept.—John Sprovieri

Automakers don’t need conveyors to transport vehicles on assembly lines—the vehicles can move themselves.—Seog-Chan Oh, Ph.D.

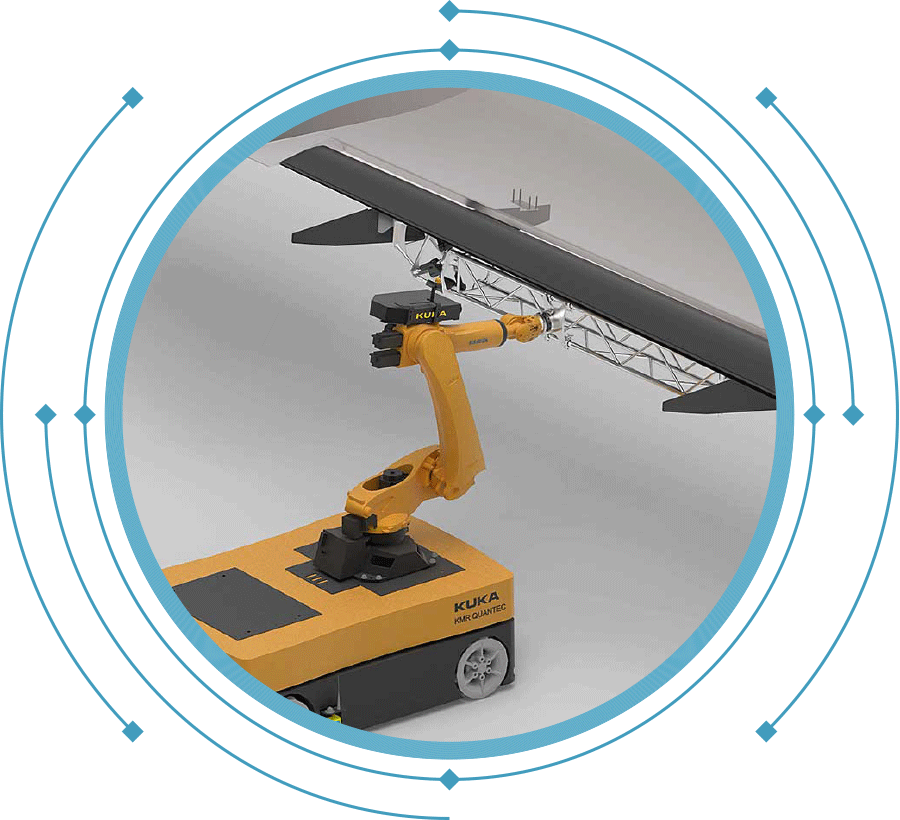

A new approach for assembling composite aerostructures uses autonomous mobile robots and lightweight assembly jigs that compensate for deformation.—Maximilian Neitmann

Researchers have developed a single end-of-arm tool that can simultaneously hold a part in place and install it at the same time.—Sangchul Han, Ph.D.

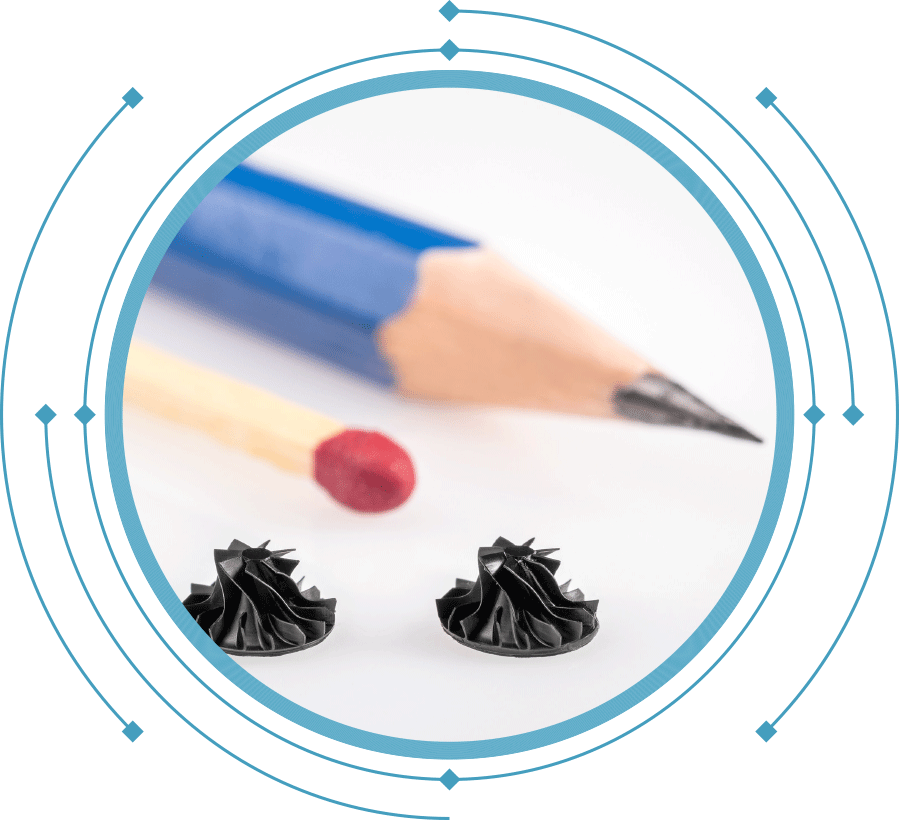

For the first time, additive manufacturing can rival the tolerances that can be achieved via micro molding.—Jon Donner

Manufacturers have made significant progress in digital transformation, but more work remains to be done.—Johannes Winter

DEPARTMENTS

This showcase displays the latest hardware, software, sensors and other technologies to help assemblers implement Industry 4.0.—Jim Camillo

Cover design by Mike Robinson

Animation courtesy HQuality Video, Creatas Video+ / Getty Images Plus

Cover animation courtesy saicle, Creatas Video+ / Getty Images Plus

FACTORY OF THE FUTURE NOVEMBER 2022